Method for preparing controlled-release nano-pesticide preparation

A nano-pesticide and preparation technology, applied in the field of pesticides, can solve problems such as agglomeration, unstable release rate, and easy crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

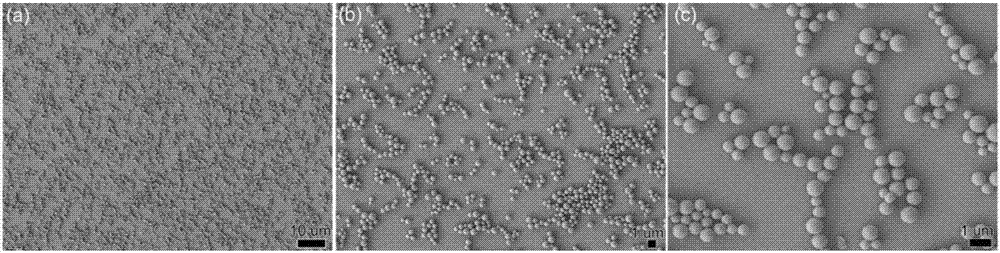

[0134] The preparation of embodiment 1 nanopesticide solid powder 1

[0135] Dissolve 2g of pesticide active ingredient avermectin in 50ml of organic solvent methylene chloride, add 2g of capsule wall material cellulose to obtain an oil phase, and dissolve 2g of emulsifying dispersant (1g of polyvinyl alcohol and 1g of agricultural milk 1601) in 200ml of water After the water phase was obtained, the oil phase and the water phase were mixed, and ultrasonically emulsified at 585W for 15 minutes using an ultrasonic pulverizer to obtain an O / W type primary emulsion, wherein the droplet size of the primary emulsion was 600nm.

[0136] The above-mentioned O / W primary emulsion was homogenized under high pressure at 900 Pa for 10 min by using a high-pressure homogenizer to obtain a miniemulsion, wherein the droplet size of the miniemulsion is 400 nm.

[0137] Stir the above-mentioned miniemulsion for 24 hours at 1500 rpm with an electric stirrer to volatilize the organic solvent to ob...

Embodiment 2

[0139] The preparation of embodiment 2 nanopesticide aqueous suspension concentrate 2

[0140] Dissolve 2g of pesticide active ingredient avermectin in 50ml of organic solvent methylene chloride, add 2g of capsule wall material cellulose to obtain an oil phase, and dissolve 2g of emulsifying dispersant (1g of polyvinyl alcohol and 1g of agricultural milk 1601) in 200ml of water After the water phase was obtained, the oil phase and the water phase were mixed, and ultrasonically emulsified at 585W for 15 minutes using an ultrasonic pulverizer to obtain an O / W type primary emulsion, wherein the droplet size of the primary emulsion was 600nm.

[0141] The above-mentioned O / W primary emulsion was homogenized under high pressure at 900 Pa for 10 min by using a high-pressure homogenizer to obtain a miniemulsion, wherein the droplet size of the miniemulsion is 400 nm.

[0142] Stir the above-mentioned miniemulsion for 24 hours at 1500 rpm with an electric stirrer to volatilize the org...

Embodiment 3

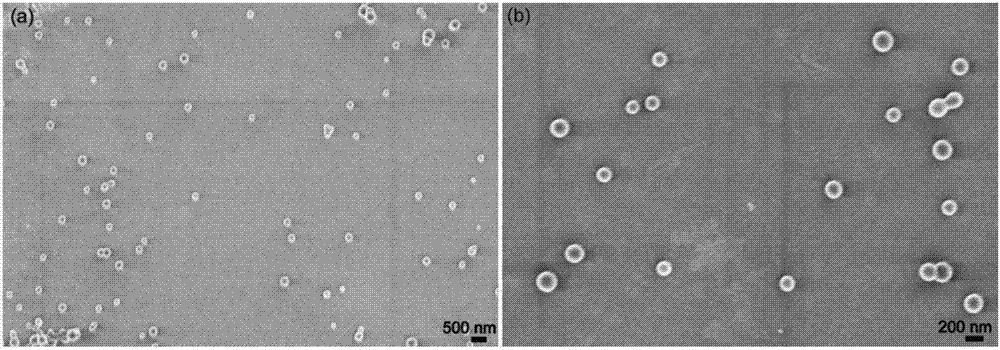

[0144] The preparation of embodiment 3 nanopesticide solid powder 3

[0145] Dissolve 2g of the pesticide active ingredient avermectin in 50ml of organic solvent methylene chloride, add 2g of polylactic acid, the capsule wall material, to obtain an oil phase, and dissolve 1g of emulsifying dispersant (0.5g of polyvinyl alcohol and 0.5g of agricultural milk 1601) in The water phase was obtained in 200ml of water, and after the oil phase and the water phase were mixed, they were sheared and emulsified at 28,000rmp for 15 minutes with a high-speed shearing machine to obtain an O / W type primary emulsion, wherein the droplet size of the primary emulsion was 300nm.

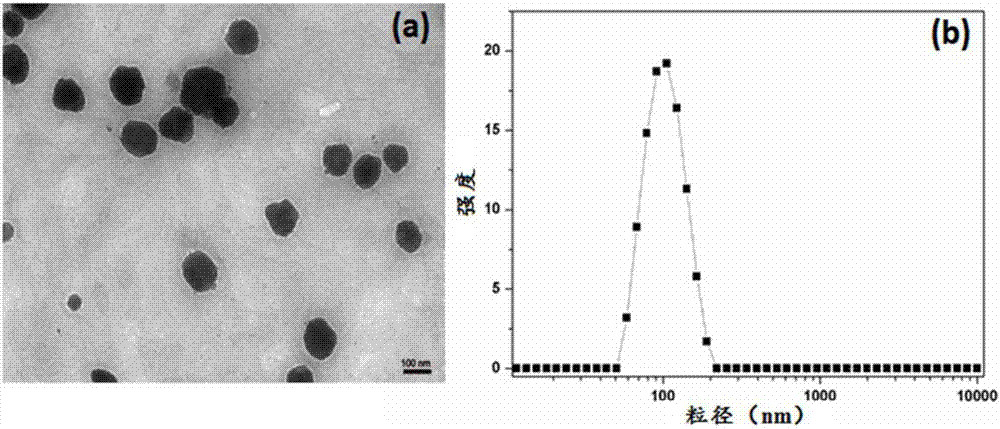

[0146] The above O / W primary emulsion was homogenized under high pressure at 900 Pa for 10 min by using a high-pressure homogenizer to obtain a mini-emulsion, wherein the droplet size of the mini-emulsion was 100 nm.

[0147] Stir the above-mentioned miniemulsion for 24 hours at 1500 rpm with an electric stirrer to vola...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com