Tiamulin famarate soluble powder

A tiamulin fumarate soluble technology is applied in the field of tiamulin fumarate soluble powder, which can solve the problems affecting the drug compliance of animals, the granulation method is not suitable for use, and it is difficult to extrude and spheronize, so as to improve bioavailability degree, no bad taste, and the effect of improving the package and sex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

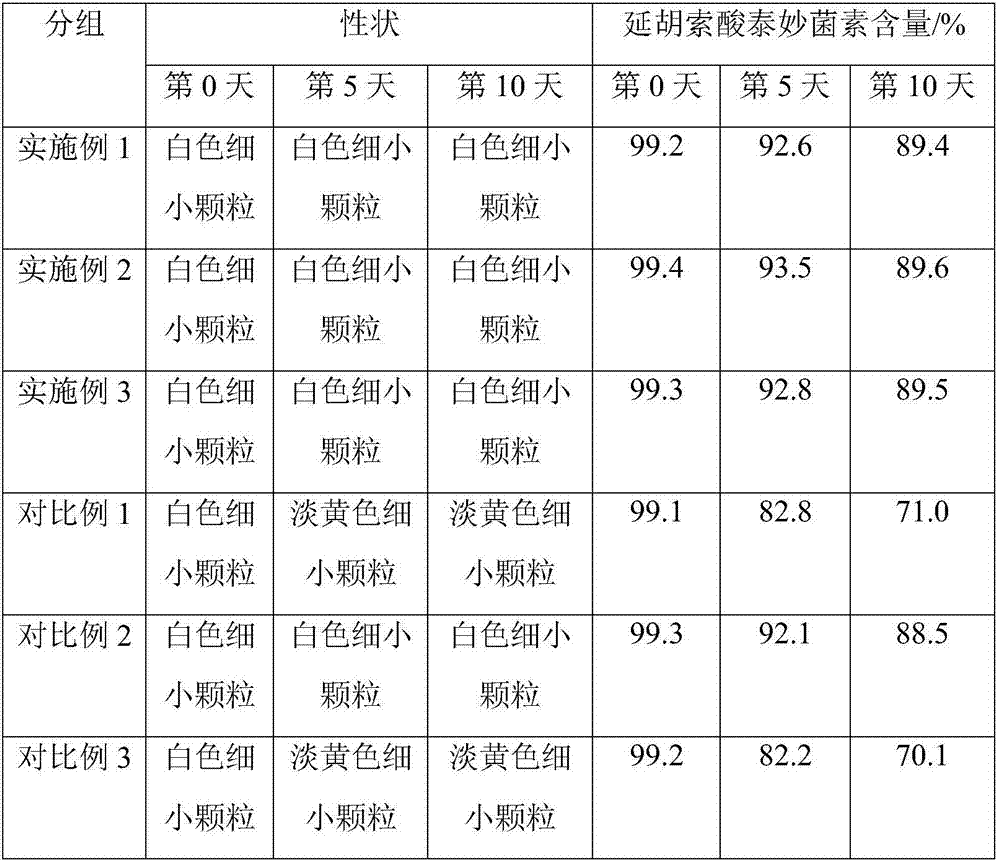

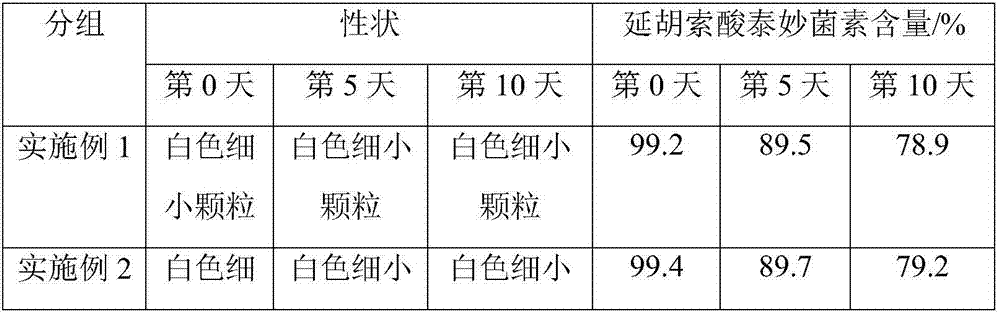

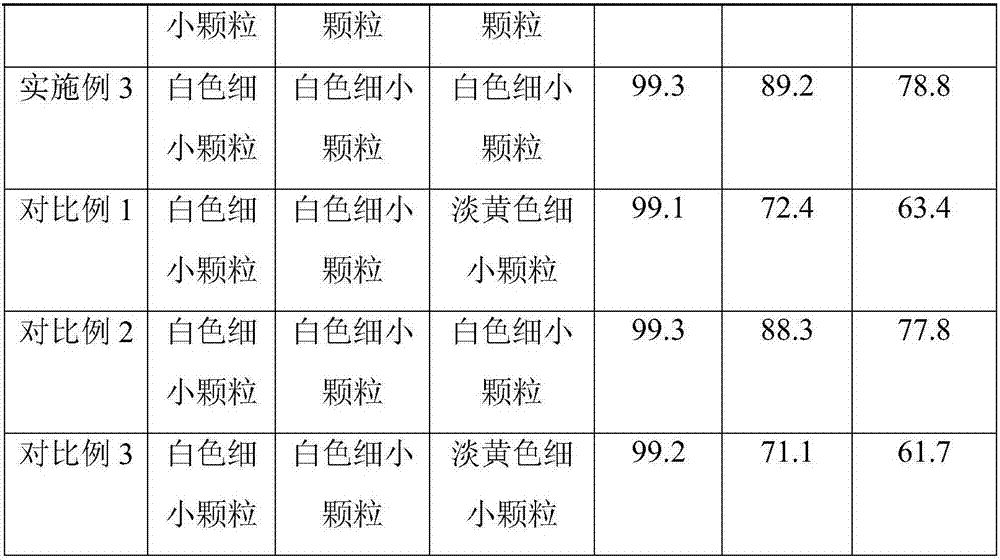

Examples

Embodiment 1

[0032] A soluble tiamulin fumarate powder is prepared from the following raw materials in parts by weight: 60 parts of tiamulin fumarate, 20 parts of pullulan-polyglutamic acid cross-linked polymer, garlic polysaccharide solid dispersion 10 parts, 9 parts of soluble starch, 4 parts of sodium alginate, 3 parts of sodium tripolyphosphate, 1.6 parts of disodium edetate, and 0.3 parts of citric acid.

[0033] As described, the pullulan-polyglutamic acid cross-linked polymer is prepared by the following method: the pullulan solution is added dropwise to the polyglutamic acid solution at a rate of 5 drops / s, at 30°C Stir and react for 2 hours under the same conditions, precipitate the mixed solution with absolute ethanol, collect the precipitate by vacuum filtration, dissolve the precipitate with deionized water, place it in a dialysis bag for dialysis for 2 hours, and freeze-dry the dialysis retentate to obtain pullulan-polygu Amino Acid Crosslinked Polymer.

[0034] Described, th...

Embodiment 2

[0050] A soluble tiamulin fumarate powder is prepared from the following raw materials in parts by weight: 55 parts of tiamulin fumarate, 25 parts of pullulan-polyglutamic acid cross-linked polymer, garlic polysaccharide solid dispersion 13 parts, 7 parts of soluble starch, 5 parts of sodium alginate, 2.5 parts of sodium tripolyphosphate, 1.3 parts of disodium edetate, and 0.4 parts of citric acid.

[0051] As described, the pullulan-polyglutamic acid cross-linked polymer is prepared by the following method: the pullulan solution is added dropwise to the polyglutamic acid solution at a rate of 5 drops / s, at 30°C Stir and react for 2 hours under the same conditions, precipitate the mixed solution with absolute ethanol, collect the precipitate by vacuum filtration, dissolve the precipitate with deionized water, place it in a dialysis bag for dialysis for 2 hours, and freeze-dry the dialysis retentate to obtain pullulan-polygu Amino Acid Crosslinked Polymer.

[0052] Described, ...

Embodiment 3

[0068] A soluble tiamulin fumarate powder is prepared from the following raw materials in parts by weight: 50 parts of tiamulin fumarate, 30 parts of pullulan-polyglutamic acid cross-linked polymer, garlic polysaccharide solid dispersion 15 parts, 5 parts of soluble starch, 6 parts of sodium alginate, 2 parts of sodium tripolyphosphate, 1 part of disodium edetate, and 0.5 part of citric acid.

[0069] As described, the pullulan-polyglutamic acid cross-linked polymer is prepared by the following method: the pullulan solution is added dropwise to the polyglutamic acid solution at a rate of 5 drops / s, at 30°C Stir and react for 2 hours under the same conditions, precipitate the mixed solution with absolute ethanol, collect the precipitate by vacuum filtration, dissolve the precipitate with deionized water, place it in a dialysis bag for dialysis for 2 hours, and freeze-dry the dialysis retentate to obtain pullulan-polygu Amino Acid Crosslinked Polymer.

[0070] Described, the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com