A copper-silver-zinc alloy with micro-nano hole structure and its preparation method and application

A zinc alloy and hole technology, which is applied in the field of copper-silver-zinc alloy and its preparation, can solve the problems of single antibacterial, difficult to recycle, easy to reunite, etc., and achieve the effect of high antibacterial and antibacterial effect improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

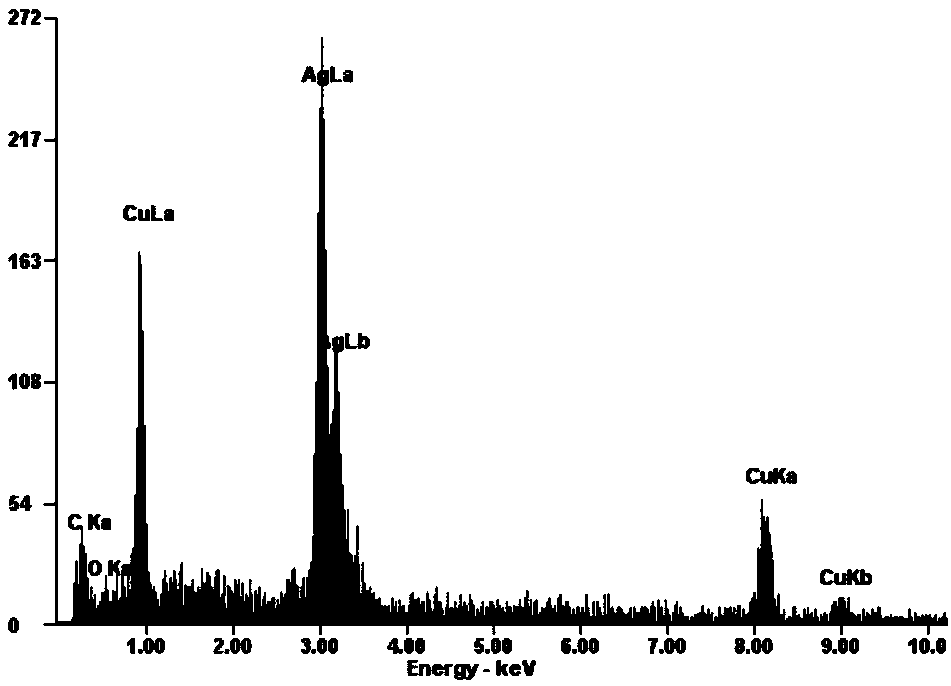

[0043] Select alloy composition Cu 45 Zr 40 Ag 10 Zn 5 , according to the atomic percentage of each element in the target alloy: Cu is 45at.%, Zr is 40at.%, Ag is 10at.%, Zn is 5at.%, and the high-purity copper sheet (7.226g that weighs mass fraction is 99.99%) ), zirconium grain (9.221g), silver grain (2.727g) and zinc grain (0.826g) obtain master alloy raw material 20g; Master alloy raw material is placed in vacuum arc melting furnace (put into 99.9wt% pure titanium before smelting granules as the oxygen-scavenging material), under the protection of high-purity argon with a purity of 99.99%, repeated melting 4 times (to ensure the uniformity of the alloy), each time about 40s. Cool down to room temperature with the furnace to get Cu 45 Zr 40 Ag 10 Zn 5 alloy ingot.

[0044] Take 2-3g of the polished and cleaned alloy ingot and place it in a quartz test tube, put the quartz test tube into a vacuum belt throwing machine and fix it in the induction coil, conduct inducti...

Embodiment 2

[0054] Select alloy composition Cu 40 Zr 35 Ag 20 Zn 5 , according to the atomic percentages of each element in the target alloy: Cu is 40at.%, Zr is 35at.%, Ag is 20at.%, Zn is 5at.%, and the mass fraction is 99.99% high-purity copper sheet (6.185g ), zirconium grain (7.769g), silver grain (5.250g) and zinc grain (0.796g) obtain master alloy raw material 20g; Master alloy raw material is placed in vacuum arc melting furnace (put into 99.9wt% pure titanium before smelting granules as the oxygen-scavenging material), under the protection of high-purity argon with a purity of 99.99%, repeated melting 4 times (to ensure the uniformity of the alloy), each time about 40s. Cool down to room temperature with the furnace to get Cu 40 Zr 35 Ag 20 Zn 5 alloy ingot.

[0055] Take 2-3g of the polished and cleaned alloy ingot and place it in a quartz test tube, put the quartz test tube into a vacuum belt throwing machine and fix it in the induction coil, conduct induction melting u...

Embodiment 3

[0061] Select alloy composition Cu 35 Zr 30 Ag 30 Zn 5 , according to the atomic percentages of each element in the target alloy: Cu is 35at.%, Zr is 30at.%, Ag is 30at.%, Zn is 5at.%, and the mass fraction is 99.99% high-purity copper sheet (5.219g ), zirconium grains (6.421g), silver grains (7.593g) and zinc grains (0.767g) to obtain 20g of the master alloy raw material; the master alloy raw material is placed in a vacuum arc melting furnace (99.9wt.% pure Titanium particles are used as oxygen-scavenging materials), and they are repeatedly smelted 4 times under the protection of high-purity argon gas with a purity of 99.99% (to ensure the uniformity of the alloy), each time for about 40s. Cool down to room temperature with the furnace to get Cu 35 Zr 30 Ag 30 Zn 5 alloy ingot.

[0062] Take 2-3g of the polished and cleaned alloy ingot and place it in a quartz test tube, put the quartz test tube into a vacuum belt throwing machine and fix it in the induction coil, con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com