Filiform corrosion resistant coating for aluminum alloy materials used for aviation

A filiform corrosion, aluminum alloy technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems that cannot meet the requirements of aviation aluminum alloy materials for filiform corrosion resistance, and achieve excellent comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

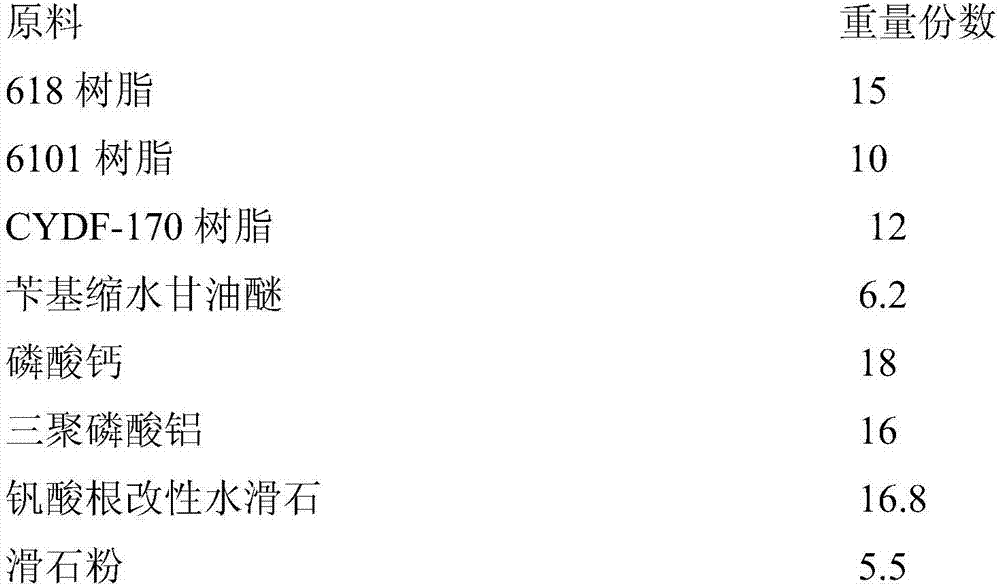

[0057] The bisphenol A type epoxy resin is selected from 618 resin and 6101 resin, and the bisphenol F type epoxy resin is selected from CYDF-170 resin; the active diluent is benzyl glycidyl ether; the antirust pigment is calcium phosphate and aluminum tripolyphosphate. The anti-settling hydrotalcite is vanadate modified hydrotalcite, the anti-settling agent is Degussa A200, the defoamer is AFCONA-2040; the wetting and dispersing agent is TEGO-671; the leveling agent is EFKA3239; the silane coupling agent is KH570; The polyamide curing agent is SF-115 produced by Changzhou Shanfeng and SF-125 produced by Changzhou Shanfeng.

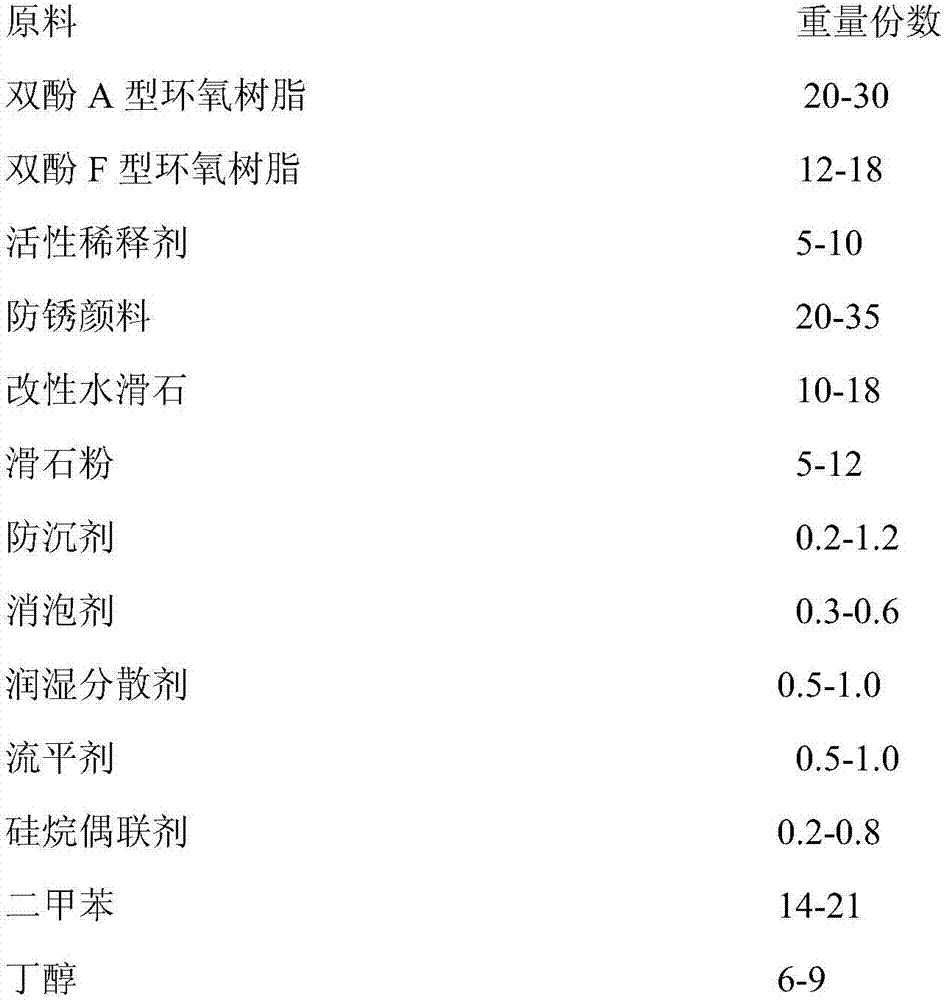

[0058] A component formula is as follows according to weight part:

[0059]

[0060]

[0061] B component formula is as follows according to weight part:

[0062]

[0063] The preparation method is as follows:

[0064] 1) The preparation method of component A is: put resin, reactive diluent, wetting and dispersing agent, defoamer, leveling agen...

Embodiment 2

[0086] In embodiment 2, bisphenol A type epoxy resin is 618 resin and 6101 resin, and bisphenol F type epoxy resin is NPEF resin; Reactive diluent is benzyl glycidyl ether; Antirust pigment is zinc phosphate and tripolymer Aluminum phosphate, modified hydrotalcite is molybdate modified hydrotalcite, anti-settling agent is Degussa A200, defoamer is AFCONA-2040; wetting and dispersing agent is TEGO-671; leveling agent is EFKA3239; silane coupling The curing agent is Deqian 1121; the polyamide curing agent is SF-115 produced by Changzhou Shanfeng and HK-125 produced by Jining Huakai.

[0087] A component formula is as follows according to weight part:

[0088]

[0089] B component formula is as follows according to weight part:

[0090]

[0091] Preparation method is the same as embodiment 1

[0092] The two components A and B are mixed evenly at a weight ratio of 5:1, and are applied by air spraying or high-pressure airless spraying.

[0093] Example 2 is prepared by co...

Embodiment 3

[0112] In embodiment 3, bisphenol A type epoxy resin is 618 resin and 6101 resin, and bisphenol F type epoxy resin is Epikote862 resin; Reactive diluent is benzyl glycidyl ether; Antirust pigment is barium borate and trimer Aluminum phosphate, modified hydrotalcite is molybdate modified hydrotalcite, anti-settling agent is Degussa A200, defoamer is AFCONA-2040; wetting and dispersing agent is TEGO-671; leveling agent is EFKA3239; silane coupling The curing agent is Deqian 1121; the polyamide curing agent is SF-115 produced by Changzhou Shanfeng and HK-125 produced by Jining Huakai.

[0113] A component formula is as follows according to weight part:

[0114]

[0115] B component formula is as follows according to weight part:

[0116]

[0117]

[0118] The preparation method is the same as in Example 1.

[0119] The two components A and B are mixed evenly at a weight ratio of 5:1, and are applied by air spraying or high-pressure airless spraying.

[0120] Example 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salt spray resistance | aaaaa | aaaaa |

| Salt spray resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com