Comprehensive recovery and treatment method for electrolytic chlorine-containing waste gas

A technology of recycling and exhaust gas recovery, applied in the electrolysis process, electrolysis components, separation methods, etc., can solve the problems of complex catalyst use, high chlorine recovery cost, increase recovery cost, etc. Environmental benefit, low cost control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

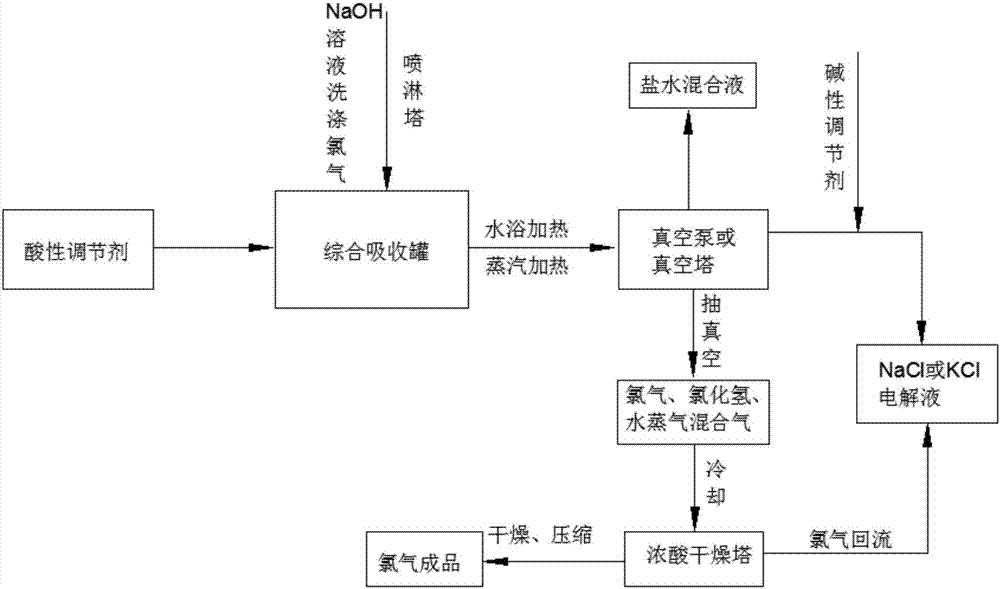

Method used

Image

Examples

Embodiment 1

[0035] In a sponge titanium production line, the waste gas produced by electrolysis of MgCl2 contains 8% chlorine (volume percentage). The chlorine-containing waste gas is collected by the tail gas recovery device. The dust solid particles then flow into the comprehensive absorption tank. The top of the comprehensive absorption tank has a spout and a spray tower. The spray tower is equipped with a NaOH solution with a concentration of 29% by weight. The NaOH solution sprays and washes the chlorine-containing waste gas in the comprehensive absorption tank through the spout on the top of the comprehensive absorption tank. The solution after the chlorine waste gas is measured by the iodometric method to contain 189.5g / l of chlorine in NaClO, and the chlorine content of NaOH is 11.6g / l as measured by the acid-base titration method. Take 500L of the mixed solution after washing, and add hydrochloric acid with a concentration of 12% by weight as an acid regulator to adjust the pH va...

Embodiment 2

[0039]A chemical plant electrolyzes NaCl to produce electrolysis waste gas with a chlorine content of 0.9% (volume percentage). The chlorine-containing waste gas is collected through the tail gas recovery device. When the mixed gas is input into the comprehensive absorption tank through the input pipeline, the dust carried by it is first removed by the dust collector. The solid particles then flow into the comprehensive absorption tank. The top of the comprehensive absorption tank has a spout and a spray tower. The spray tower is equipped with a NaOH solution with a concentration of 32% by weight. The NaOH solution sprays and washes the chlorine-containing waste gas in the comprehensive absorption tank through the spout on the top of the comprehensive absorption tank. The solution after the chlorine waste gas was measured by iodometric method to contain 79.5g / l of chlorine in NaClO, and the chlorine content of NaOH was 65.3g / l as measured by acid-base titration. Get the mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com