Adsorption photocatalytic hydrogel material and application thereof in synergistic photocatalytic sewage hydrogen generation capable of reversing heavy metal pollution

A photocatalytic and hydrogel technology, applied in the direction of adsorption of water/sewage treatment, alkali metal oxides/hydroxides, alkali metal compounds, etc., can solve the problems of quenching photogenerated electrons and affecting the hydrogen production performance of photocatalysts, etc. Achieve the effects of reversing the poisonous effect, good light transmission, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

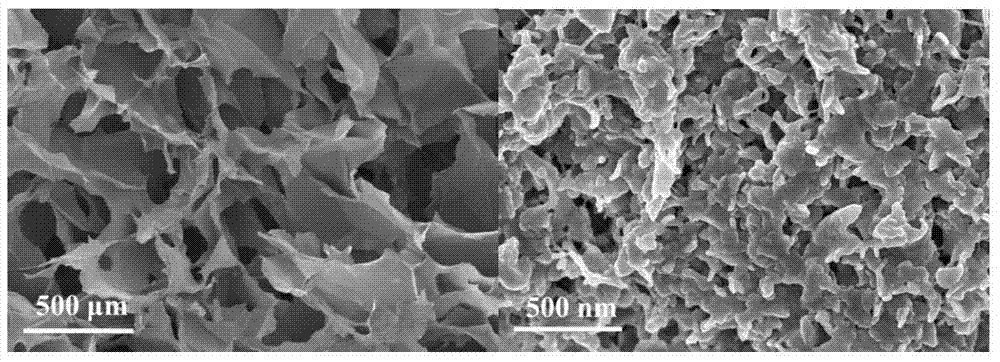

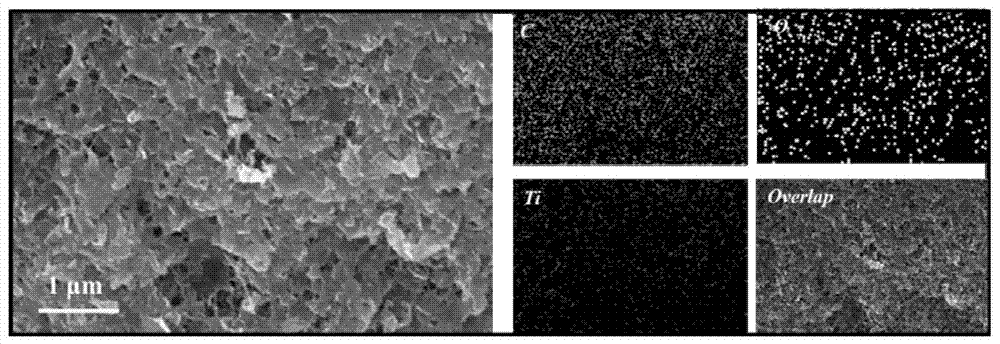

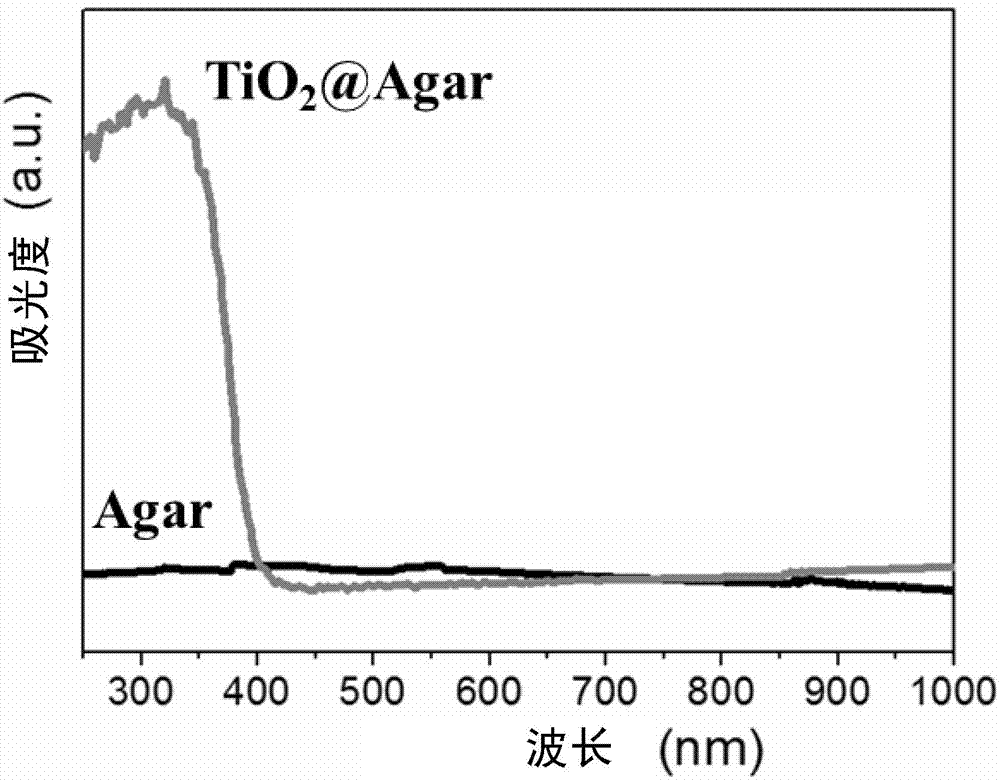

[0054] 20mg of photocatalytic nanomaterial TiO prepared by sol-hydrothermal method 2 Disperse in 10ml of deionized water and ultrasonicate for 1 hour to prepare a uniform mixed solution. 150 mg of agarose (G-10, EEO 0.1) was added to the mixed solution after ultrasonic dispersion, heated to 90° C., and kept for 5 minutes. Pour the mixed solution into a watch glass with a diameter of 10 cm, quickly cool it to room temperature, and take it out after solidification to obtain the designed adsorption photocatalytic hydrogel material (TiO 2 @Agar).

[0055] After that, the TiO 2 @Agar hydrogel immersed in the metal ion solution, after 6 hours of light, the TiO adsorbed with heavy metal ions 2 @Agar Take it out, immerse it in 50ml of sodium sulfide solution (0.5mg / ml), stir, so that the adsorbed heavy metal ions fully react with the sulfur ions in the solution, and transform into corresponding metal sulfide semiconductors. After half an hour, take out the TiO after vulcanization ...

Embodiment 2

[0057] 10 mg of photocatalytic nanomaterial carbon nitride (C 3 N 4 ) was dispersed in 10ml of deionized water and ultrasonicated for 1 hour to prepare a uniform mixed solution. Add 100 mg of agarose (G-10, EEO 0.1) to the mixed solution after ultrasonic dispersion, heat to 90° C., and keep warm for 2 minutes. Pour the mixed solution into a watch glass with a diameter of 10 cm, quickly cool it to room temperature, take it out after solidification, and obtain another adsorption photocatalytic hydrogel material (denoted as C 3 N 4 @Agar).

[0058] After that, put C 3 N 4 @Agar hydrogel immersed in the metal ion solution, after 6 hours of light, the C adsorbed with heavy metal ions 3 N 4 @Agar Take it out, immerse it in 50ml of potassium sulfide solution (0.5mg / ml), stir, so that the adsorbed heavy metal ions fully react with the sulfur ions in the solution, and transform into corresponding metal sulfide semiconductors. After 10 minutes, remove the vulcanized C 3 N 4 @Aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com