Two-dimensional reticular hairline nanometer fiber material used for air filtration and preparation method of material

A two-dimensional mesh and air filtration technology, which is applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of inability to achieve material filtration performance, low filtration efficiency of small particle size particles, and easy-to-collapse pore structure. Achieve continuous and seamless stacking, facilitate gas passage, and enhance structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A two-dimensional net-like ultra-fine nanofiber material for air filtration and a preparation method thereof, the steps are as follows:

[0030] 1) Dissolve silver nitrate in tetrahydrofuran, stir with a magnetic stirrer for 60 minutes, and ultrasonically perform 20 minutes with a sonicator. The content of silver nitrate is 0.002wt% of the total mass of the polymer solution, and then the granular polystyrene polymer with a molecular weight of 1.0 ×10 7 , added to the tetrahydrofuran solvent dissolved with silver nitrate, stirred at room temperature for 6 hours to obtain a uniform and stable polymer solution, the mass concentration of polystyrene in the solution was 0.01wt%, and the viscosity of the obtained solution was 350mPa·s.

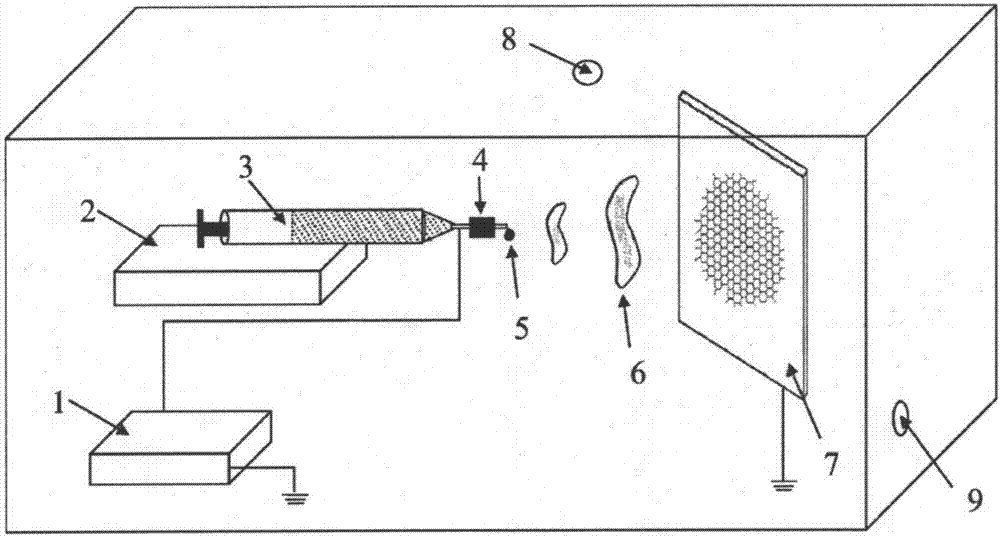

[0031] 2) Using the device shown in the accompanying drawings, the above-mentioned polymer solution obtained is transported to the spinneret of the spraying device 3 through the liquid supply system 2, the spraying device is connected to a DC...

Embodiment 2

[0033] A two-dimensional net-like ultra-fine nanofiber material for air filtration and a preparation method thereof, the steps are as follows:

[0034] 1) Lithium chloride is dissolved in N,N-dimethylacetamide, stirred by a magnetic stirrer for 10min, and ultrasonically ultrasonicated for 15min. The content of lithium chloride is 0.00075wt% of the total mass of the polymer solution, and then the granular Polyurethane polymer with a molecular weight of 1.2×10 7 , was added to the N,N-dimethylacetamide solvent dissolved with lithium chloride, stirred at room temperature for 5h to obtain a uniform and stable polymer solution, the mass concentration of polyurethane in the solution was 0.005wt%, and the viscosity of the resulting solution was 200mPa·s.

[0035] 2) Using the device shown in the accompanying drawings, the above-mentioned obtained polymer solution is transported to the spinneret of the spraying device 3 through the liquid supply system 2, the spraying device is conne...

Embodiment 3

[0037] A two-dimensional net-like ultra-fine nanofiber material for air filtration and a preparation method thereof, the steps are as follows:

[0038] 1) Sodium chloride is dissolved in N,N-dimethylacetamide, stirred by a magnetic stirrer for 40min, supersonicated by an ultrasonic instrument for 10min, the content of sodium chloride is 0.0001wt% of the total mass of the polymer solution, and then the granular Ethylene-vinyl alcohol copolymer, molecular weight 2×10 7 , added to N,N-dimethylacetamide dissolved with sodium chloride, stirred for 2 hours under 60°C water bath conditions, to obtain a uniform and stable polymer solution, the mass concentration of ethylene-vinyl alcohol copolymer in the solution was 0.001wt %, the viscosity of the resulting solution is 100mPa·s.

[0039] 2) Using the device shown in the accompanying drawings, the polymer solution obtained above is transported to the spinneret of the spraying device 3 through the liquid supply system 2, the spraying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Aperture range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com