A kind of non-woven fabric based forward osmosis membrane and its preparation method and application

A forward osmosis membrane and non-woven fabric-based technology, which is applied in the field of non-woven fabric-based forward osmosis membrane and its preparation, can solve the problems of water flux and permeability that need to be further improved, and achieve high strength, good physical properties, and improved flux effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

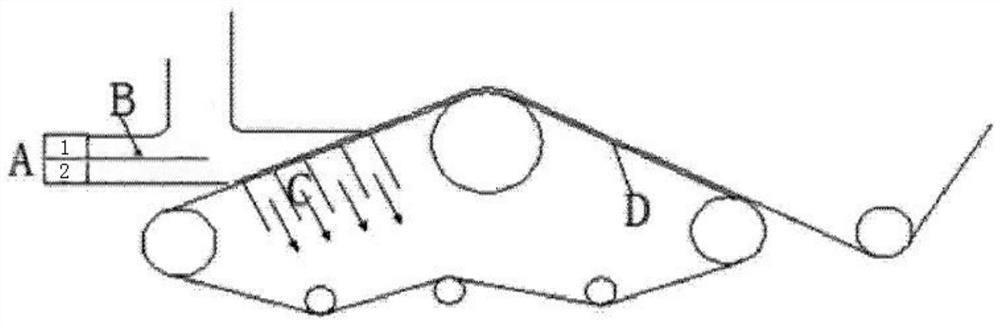

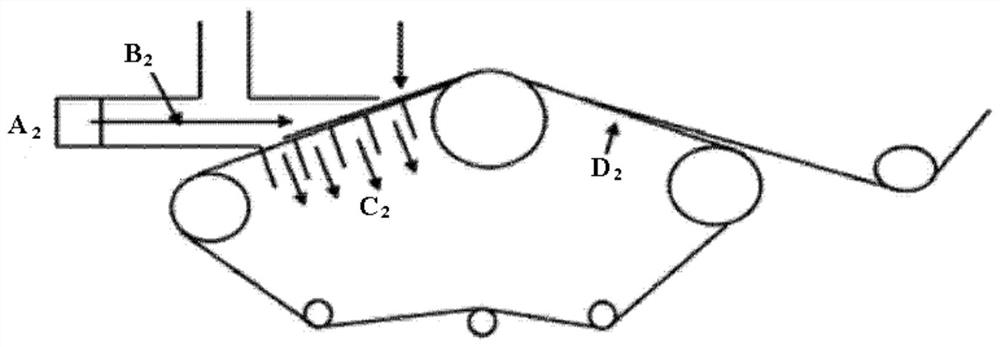

[0035] (1) Preparation of non-woven fabric support layer: the fiber raw material is mixed with water according to the fiber composition listed in Table 1, beating, and diluted to 0.05wt%, to obtain a slurry, and the gained slurry is loaded into an inclined wire paper machine, and passed through a wet process The papermaking process is used to form a non-woven fabric support layer. The basic properties of the resulting nonwoven support layer are shown in Table 2.

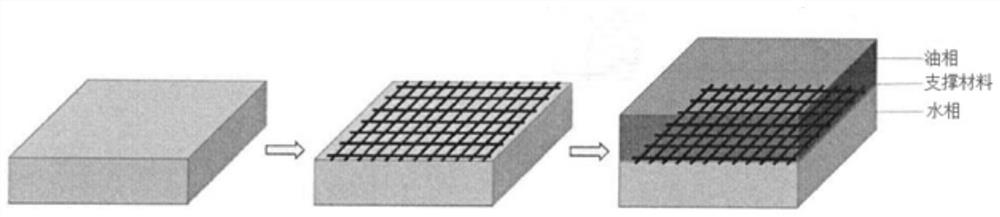

[0036] (2) Preparation of aqueous phase solution and oil phase solution: the aqueous phase solution solvent is deionized water, the solute is m-phenylenediamine and polyethyleneimine, and the concentration is 20g / L and 1.0g / L respectively, and the pH value of the aqueous phase solution adjusted to 10.5; the solvent of the oil phase solution is n-hexane, the solute is trimesoyl chloride, and the concentration is 1.0g / L.

[0037](3) Interfacial polymerization to obtain the polyamide active layer: add an appropriate am...

Embodiment 2

[0039] Compared with Example 1, the preparation method of a non-woven fabric-based forward osmosis membrane in this example is different in that the concentration of polyethyleneimine in the aqueous phase solution is 2.0 g / L, and the remaining steps and parameters are exactly the same .

Embodiment 3

[0041] Compared with Example 1, the method for preparing a non-woven fabric-based forward osmosis membrane in this example differs in that the concentration of phenylenediamine in the aqueous phase solution is 25 g / L, and the rest of the steps and parameters are identical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com