Method for quickly depositing graphene on glass surface through metal-free catalysis

A metal-free catalysis, glass surface technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve problems such as instability, high price, brittleness, etc., to improve density, improve electrical conductivity, and optimize experimental conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0036] The glass slides were ultrasonically cleaned with acetone, absolute ethanol, and deionized water for 10 min, and then dried with nitrogen gas for later use.

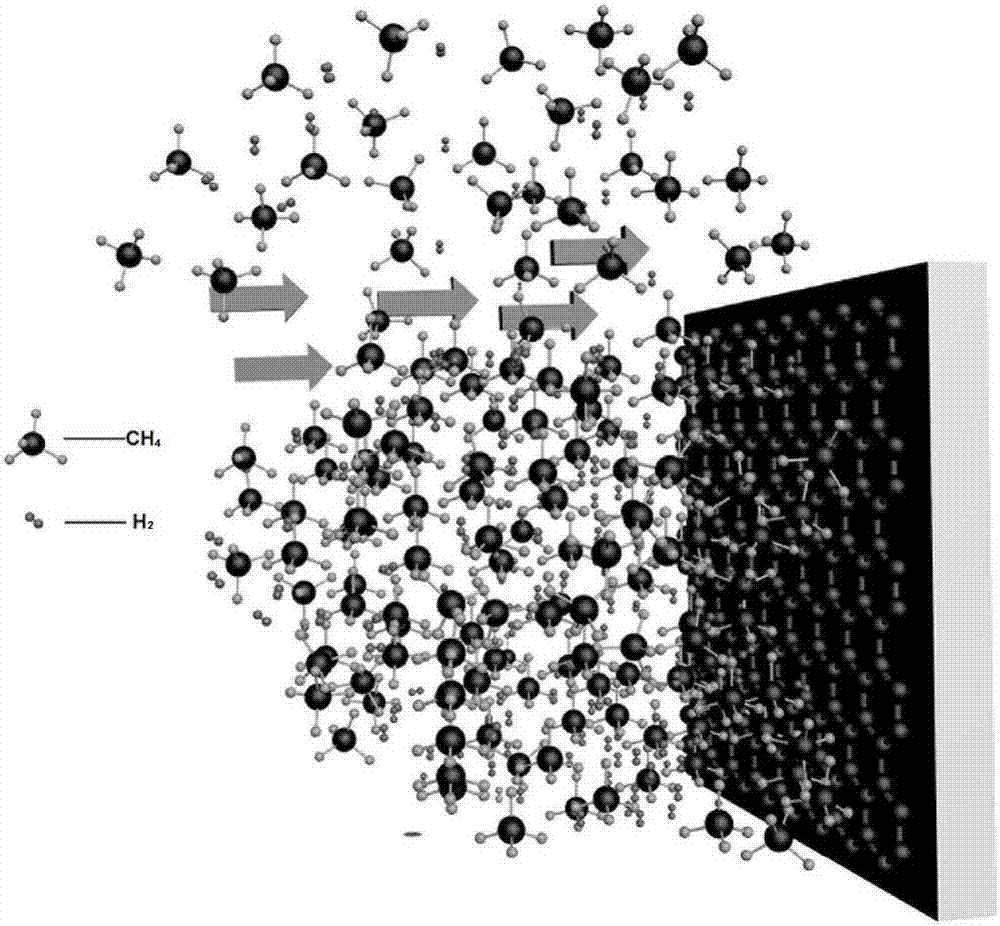

[0037] The dried glass sheet is placed on a special support so that the glass surface is perpendicular to the direction of the horizontal airflow, and then placed in the center of the quartz tube. After sealing, turn on the vacuum pump to evacuate the vacuum in the quartz tube to 20Pa, and finally use argon to backfill the quartz tube to normal pressure.

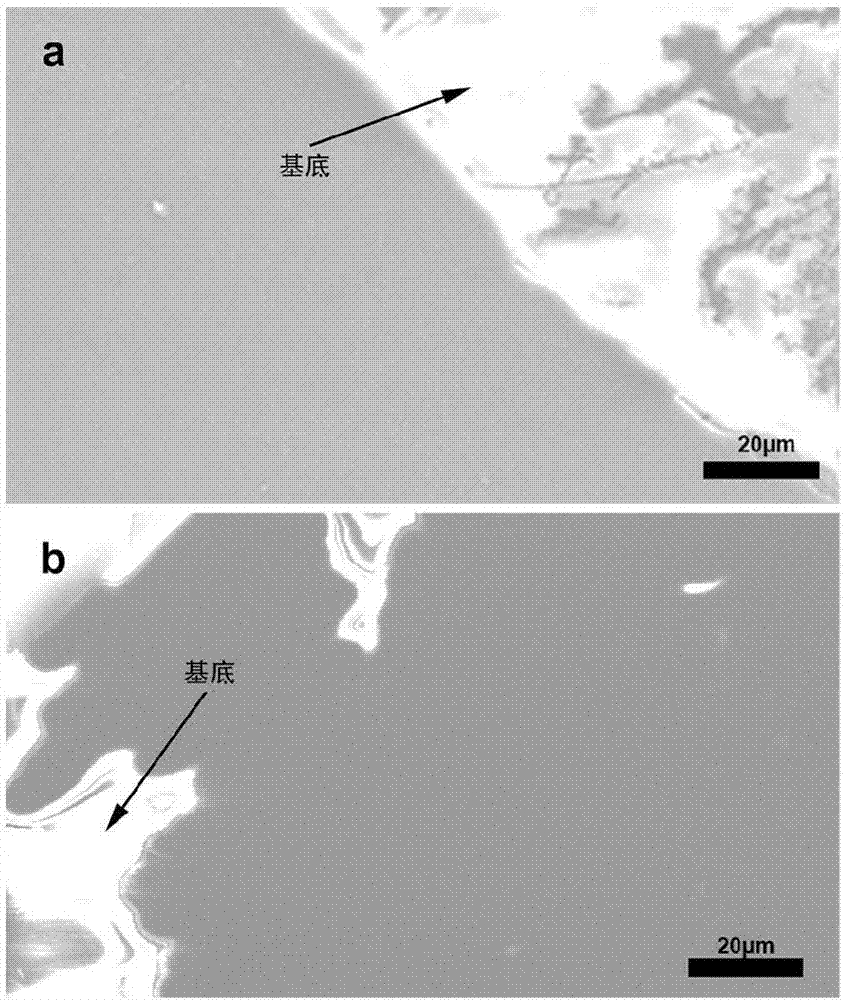

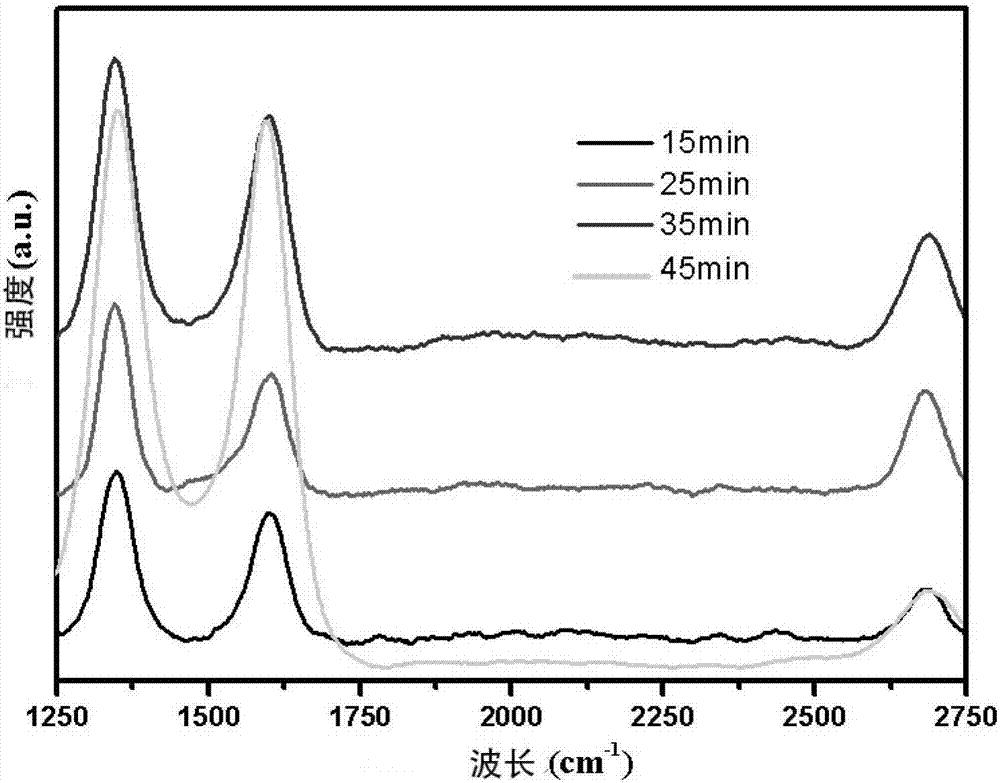

[0038] Heat the quartz tube from room temperature to 1050°C at a heating rate of 15°C / min, keep the flow rates of argon and hydrogen at 150sccm and 30sccm respectively during the process, anneal for 10 minutes after the temperature reaches 1050°C, and introduce 8sccm of methane as the carbon source. Grow for 35min, then turn off the methane, and cool naturally to room temperature under the mixed gas of argon (150sccm) and hydrogen (30sccm), to obtain graphene gl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com