A starch-based microporous hemostatic material with antibacterial properties and its preparation method and application

A hemostatic material, starch-based technology, applied in pharmaceutical formulations, bandages, drug delivery, etc., to achieve good degradation performance, good biocompatibility, and good antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] Preparation method of starch-based microporous hemostatic material

[0066] The preparation method of the starch-based microporous hemostatic material of the present invention comprises the following steps:

[0067] (1) Preparation of microporous starch

[0068] Add starch and enzyme to phosphate buffer, stir at 40-80°C and pH 4-8, carry out enzymolysis reaction, after 3-16 hours, separate by suction filtration, dry to obtain microporous starch; ,

[0069] The mass ratio of the starch and the enzyme is 1: (0.01-0.3);

[0070] The mass volume ratio of the total amount of the starch and enzyme to the phosphate buffer is 100g: (150-1000) mL;

[0071] (2) Cationization of microporous starch

[0072] Mix and stir the microporous starch, cationic modifier, catalyst and water prepared in step (1) according to a certain ratio, keep stirring and insulate for reaction at 30-80°C for 4-30 hours, and mix with water-isopropanol After the mixed solution is centrifuged and washed...

Embodiment 1

[0110] (a) Preparation of microporous starch

[0111] Add 100g of cornstarch and 3g of glucoamylase into 300mL of phosphate disodium hydrogen phosphate aqueous buffer solution with pH=6, stir evenly, carry out enzymolysis reaction at 45°C for 8h, vacuum filter and wash, and freeze-dry Dry in the machine for 20 hours to obtain corn microporous starch.

[0112] (b) Cationization of microporous starch

[0113] Dissolve 10g of corn microporous starch in 45g of water, add 0.25g of potassium hydroxide and 3.0g of methylene dimethylamine hydrochloride, stir well, react at 50°C for 20h, and carry out the reaction with a mixture of water and isopropanol Wash by centrifugation and dry in a freeze dryer for 20 hours to obtain aminated corn microporous starch. Sample form such as figure 1 shown.

Embodiment 2~5

[0115] Examples 2-5 Repeat the experimental steps of Example 1, the difference lies in some experimental conditions, as shown in Table 1-2.

[0116] Table 1 Preparation of microporous starch

[0117]

[0118] Table 2 Cationization of microporous starch

[0119]

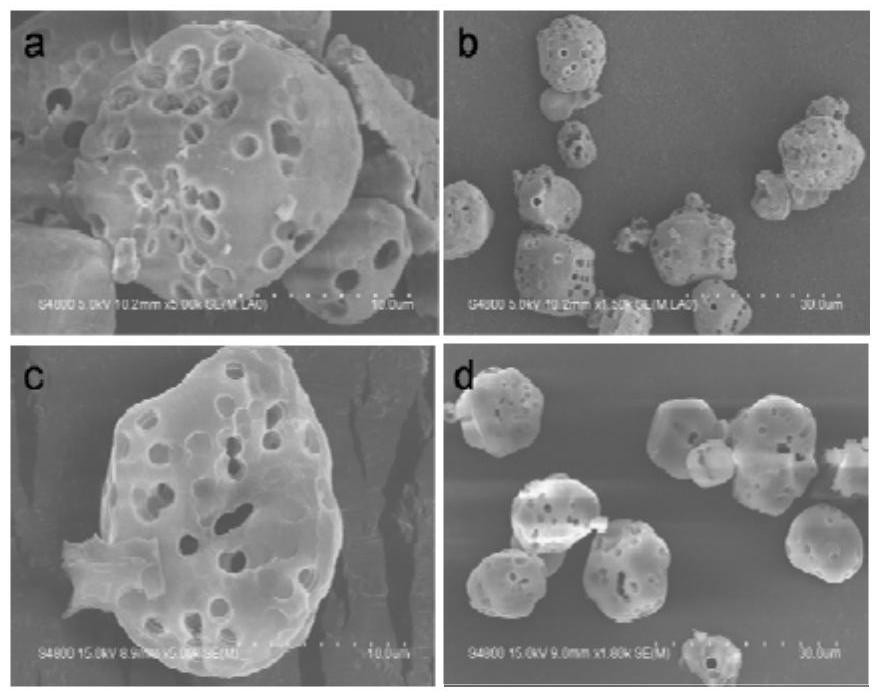

[0120] Adopt scanning electron microscope to observe respectively the microporous starch (see figure 2 (a) and 2 (b)) and the microporous starch (see figure 2 (c) and 2(d)). It can be seen from the figure that the microporous starch without amino groups has a particle diameter of about 10-20 μm and a pore diameter of about 1-4 μm, and the micropores remain intact after amino group modification.

[0121] The amino group-loaded microporous starch prepared in Example 2-5 has a particle diameter of about 9-30 μm and a pore diameter of about 0.5-5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com