Aluminum alloy cutting fluid and preparation method thereof

A technology of cutting fluid and aluminum alloy, applied in lubricating composition, petroleum industry, etc., can solve the problems of endangering human health, chronic poisoning, etc., and achieve the effect of strong antibacterial and bactericidal ability, low toxicity, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

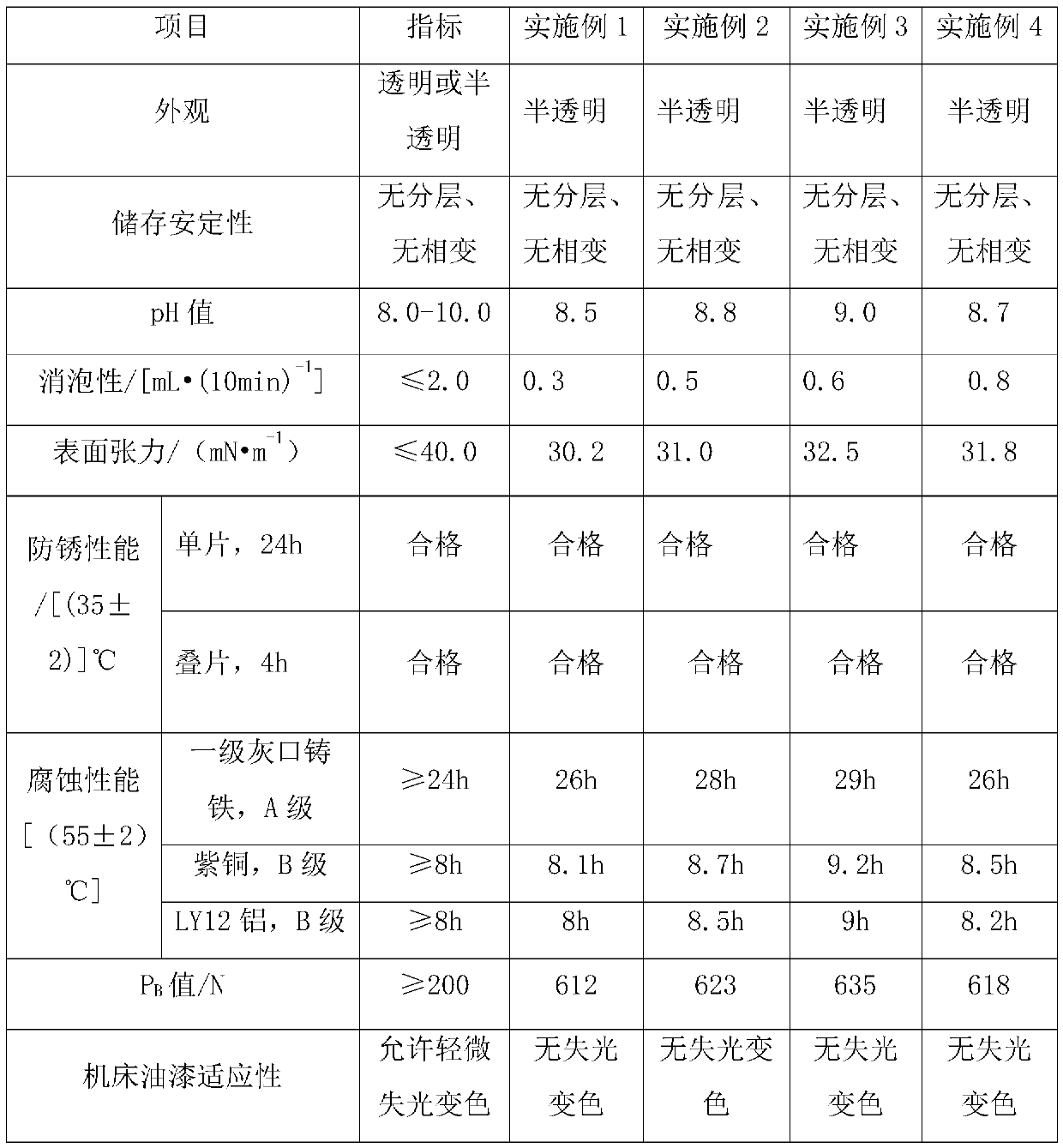

Examples

Embodiment 1

[0026] Raw materials of aluminum alloy cutting fluid (by weight): naphthenic oil 15%, sulfur-nitrogen borate 5%, potassium borate 3%, triethanolamine oleate 2%, nonionic surfactant 4%, anionic surface Active agent 2%, corrosion inhibitor 1%, rust inhibitor 1%, stabilizer 0.5%, defoamer 0.1%, compound bactericide 0.1%, and the balance is deionized water.

[0027] Anionic surfactant is composed of fatty alcohol polyoxyethylene ether sodium sulfate and polyoxyethylene ether disodium sulfosuccinate, and the weight ratio of fatty alcohol polyoxyethylene ether sodium sulfate to polyoxyethylene ether disodium sulfosuccinate is 1 -2:1.

[0028] The corrosion inhibitor is polyaspartic acid.

[0029] The rust inhibitor is a water-based rust inhibitor, and the water-based rust inhibitor is composed of diethylene glycol monobutyl ether, sorbitol, triethanolamine, diethanolamine borate, acrylate and deionized water. The weight ratio of butyl ether, sorbitol, triethanolamine, diethanolami...

Embodiment 2

[0036] Raw materials of aluminum alloy cutting fluid (by weight): naphthenic oil 20%, sulfur-nitrogen borate 6%, potassium borate 4%, triethanolamine oleate 3%, nonionic surfactant 5%, anionic surface Active agent 3%, corrosion inhibitor 2%, rust inhibitor 2%, stabilizer 1.0%, defoamer 0.5%, compound bactericide 0.2%, and the balance is deionized water.

[0037] Anionic surfactant is composed of fatty alcohol polyoxyethylene ether sodium sulfate and polyoxyethylene ether disodium sulfosuccinate, and the weight ratio of fatty alcohol polyoxyethylene ether sodium sulfate to polyoxyethylene ether disodium sulfosuccinate is 1 -2:1.

[0038] The corrosion inhibitor is a mixture of polyaspartic acid and benzotriazole.

[0039] The rust inhibitor is a water-based rust inhibitor, and the water-based rust inhibitor is composed of diethylene glycol monobutyl ether, sorbitol, triethanolamine, diethanolamine borate, acrylate and deionized water. The weight ratio of butyl ether, sorbitol...

Embodiment 3

[0044] Raw materials of aluminum alloy cutting fluid (by weight): naphthenic oil 30%, sulfur-nitrogen borate 8%, potassium borate 5%, triethanolamine oleate 4%, nonionic surfactant 8%, anionic surface Active agent 4%, corrosion inhibitor 3%, rust inhibitor 3%, stabilizer 2%, defoamer 1.0%, compound fungicide 0.5%, and the balance is deionized water.

[0045]Anionic surfactant is composed of fatty alcohol polyoxyethylene ether sodium sulfate and polyoxyethylene ether disodium sulfosuccinate, and the weight ratio of fatty alcohol polyoxyethylene ether sodium sulfate to polyoxyethylene ether disodium sulfosuccinate is 1 -2:1.

[0046] The corrosion inhibitor is a mixture of sodium metasilicate, tetraethoxysilane and methyltrimethoxysilane.

[0047] The rust inhibitor is a water-based rust inhibitor, and the water-based rust inhibitor is composed of diethylene glycol monobutyl ether, sorbitol, triethanolamine, diethanolamine borate, acrylate and deionized water. The weight ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com