A recycling method for waste varistors

A varistor and processing method technology, applied in the field of electronic waste resource utilization, can solve problems such as endangering the health of operators, insufficient solder removal, polluting the surrounding environment, etc., achieving objective economic value, less labor-intensive operation, and recycling. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

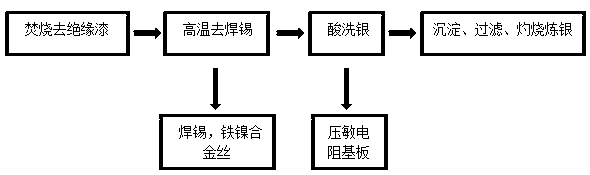

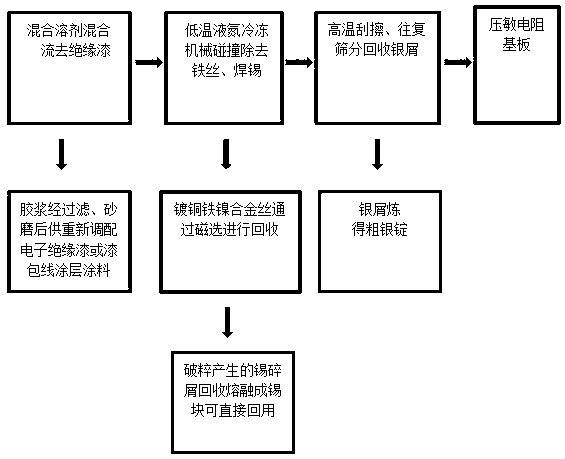

Method used

Image

Examples

Embodiment

[0020] After washing and drying 200Kg of recycled material with skin, use 300Kg of mixed solvent for reflux washing. The proportion of mixed solvent is as follows: N-methylpyrrolidone 120Kg, propylene glycol methyl ether butyrate 50Kg, methyl cyclohexyl ester 50Kg and 120 # Petroleum ether 80Kg, heat the mixed solvent in an oil bath to 160°C and reflux until the recycled material completely turns into glue, filter the glue while it is hot, grind it in a sand mill after cooling, adjust the solid content to 40%, seal it and store it for later use, the obtained The weight of the material after washing off the insulating paint is 147Kg, and it enters the next step of the process;

[0021] Add 147Kg of insulating paint leather material to the double-layer closed horizontal mixing drum with a safety release valve, then add 6Kg of liquid nitrogen, close the horizontal mixing drum and let it stand for 20 minutes, then stir for 60 minutes, then add 3Kg of liquid nitrogen, and close the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com