Preparation method of niobium-doped stannic oxide monocrystal film with high migration rate

A single crystal thin film and tin oxide technology, which is applied in the field of preparation of high mobility niobium doped tin oxide single crystal thin film, can solve the problems that are difficult to meet the application standards of devices, high mobility and low defect density, and affect the electrical properties of materials, etc. , to achieve the effect of excellent photoelectric performance, excellent electrical and optical performance, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

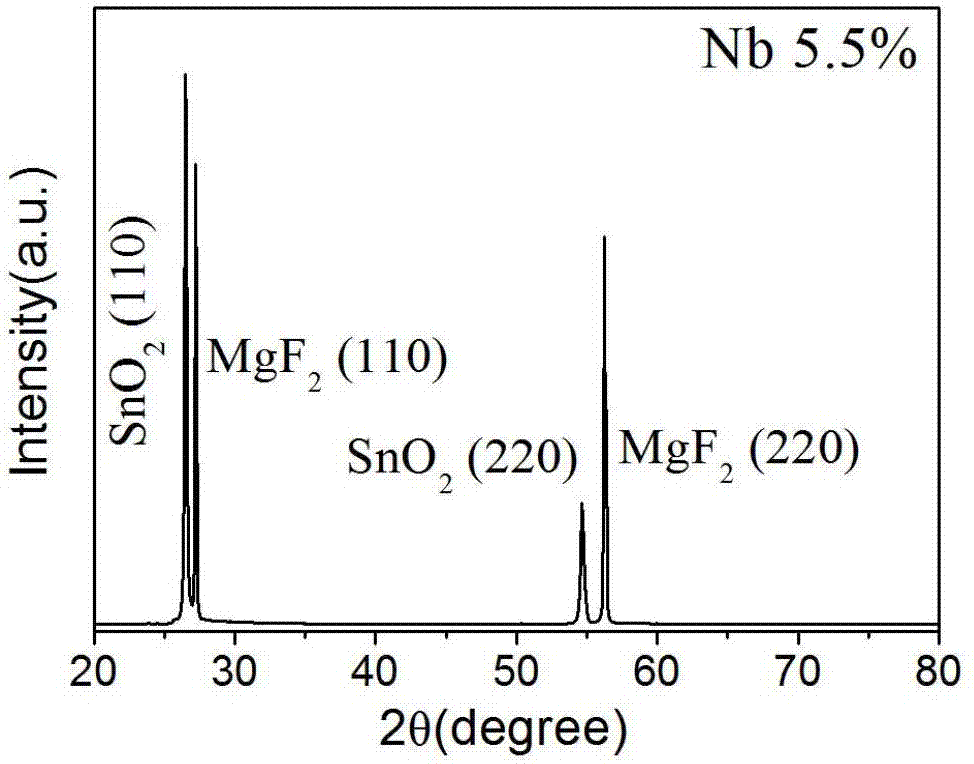

[0061] Example 1: Nb doping ratio is 5.5%

[0062] Nb-doped tin oxide thin film materials were prepared by MOCVD technology. The polished magnesium fluoride (110) surface was used as the substrate, and Sn(C 2 h 5 ) 4 As an organometallic tin source, Nb(C 2 h 5 O) 5 As an organometallic niobium source, the steps are as follows:

[0063] (1) First pump the reaction chamber of the MOCVD equipment to a high vacuum state of 5×10 -4 Pa, heat the substrate to 660°C;

[0064] (2) Open the valve of the nitrogen cylinder and feed nitrogen into the reaction chamber (background N 2 )500sccm, 30 minutes, make the reaction chamber pressure

[0065] The strong is 30Torr;

[0066] (3) Open the valve of the oxygen cylinder, adjust the flow rate of oxygen to 50 sccm, and keep it for 10 minutes;

[0067] (4) Open the valve of the organometallic Sn source bottle and adjust the carrier gas N 2 Flow 20sccm, keep for 10 minutes;

[0068] (5) open the organometallic Nb source bottle valve...

Embodiment 2

[0076] Example 2: Preparation of niobium-doped single crystal tin oxide thin film material by MOCVD technology, changing the Nb doping ratio

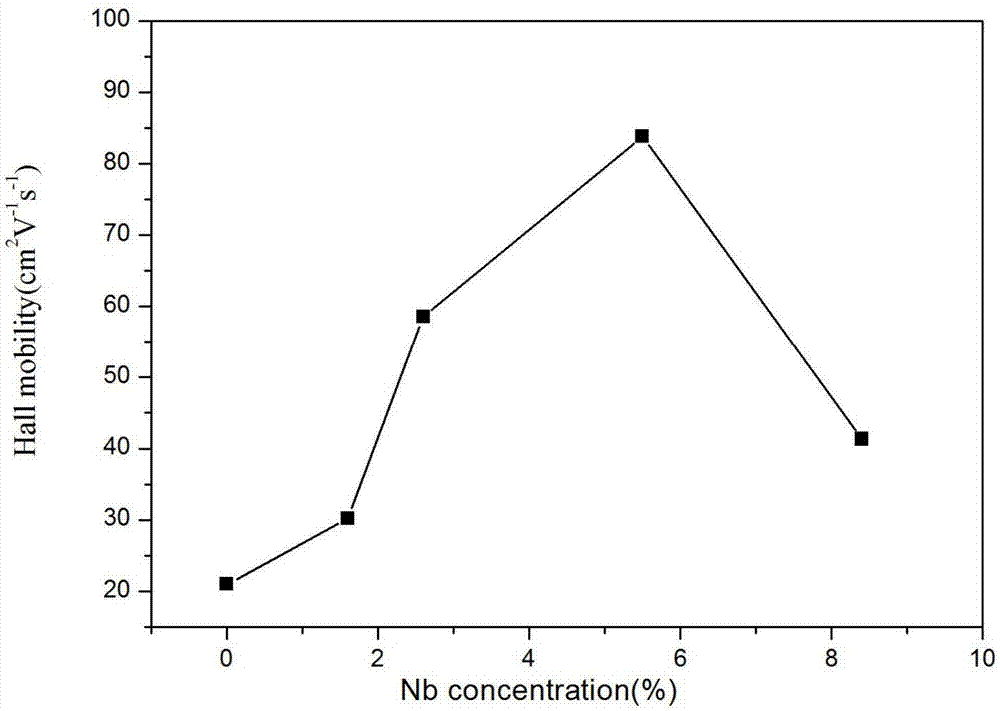

[0077] The preparation steps are as described in Example 1, the difference is that the flow rate of the Nb source is changed, so that the Nb doping ratio is 1.6%, 2.6% and 8.4%, and the prepared films are all single crystal structures, and the carrier migration of the films Rate is 30.2cm 2 V -1 the s -1 、58.5cm 2 V -1 the s -1 and 41.3cm 2 V -1 the s -1 , with the increase of Nb doping ratio, the Hall shift of the film first increases and then decreases, as image 3 shown. The average relative transmittance in the visible light range is 74%, 80% and 68%, respectively, such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| optical band gap | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com