Antibiosis acrylic fiber and preparation method thereof

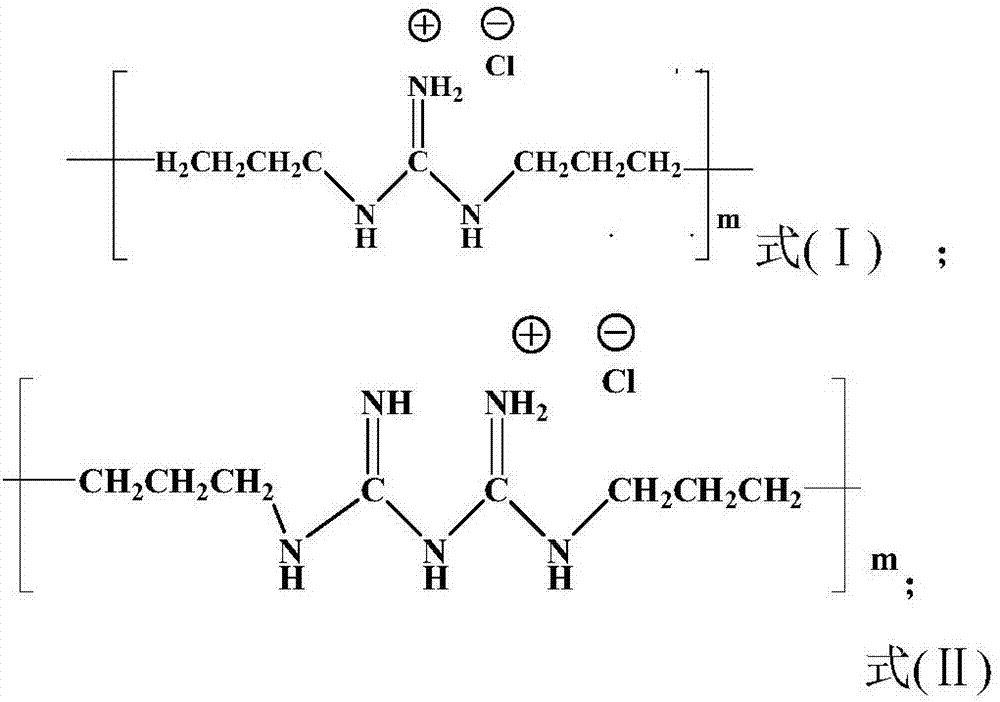

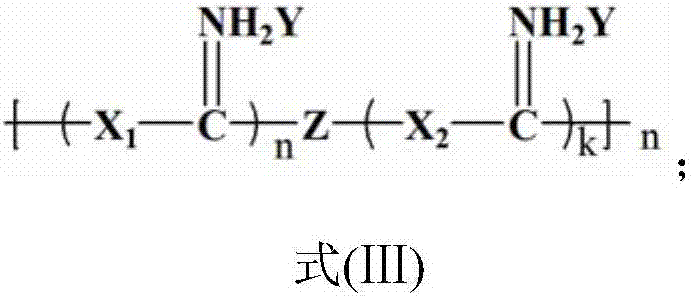

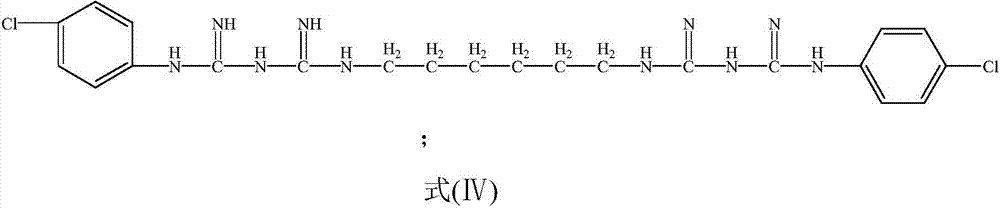

An acrylic fiber and antibacterial agent technology, which is applied in the field of fiber manufacturing, can solve the problems of poor antibacterial and antibacterial washing resistance of fibers, long technical route of antibacterial acrylic fiber, and difficulty in solvent recycling, and achieves good antibacterial washing resistance and antibacterial washing resistance. Excellent, broad-spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A kind of preparation method of antibacterial acrylic fiber, its step is as follows:

[0047] (1) Preparation of acrylic fiber: acrylic fiber spinning solution is extruded through spinneret, solidified at 5°C, water-bath stretching and washing at 80°C to obtain acrylic fiber, wherein acrylic fiber is a copolymer with acrylonitrile content of 80.1wt%. The viscosity-average molecular weight of acrylic fiber is 22,000, and the content of the third monomer itaconic acid in the acrylic fiber is 0.5wt%, and the mass concentration of solvent in the acrylic fiber spinning solution is 90%, and the solvent is 9wt% sodium thiocyanate aqueous solution, spinning The extruding temperature of the head is 70°C, the velocity is 5m / s, the solidified coagulation bath is composed of water and dimethylacetamide, the mass concentration of dimethylacetamide in the coagulation bath is 5%, and the temperature of the water bath stretching is 60°C, stretching ratio is 2;

[0048] (2) Bath immers...

Embodiment 2

[0052] A kind of preparation method of antibacterial acrylic fiber, its step is as follows:

[0053] (1) Preparation of acrylic fiber: the acrylic fiber is extruded through the spinneret, solidified at 30°C, stretched in a water bath and washed at 98°C to obtain the acrylic fiber, wherein the acrylic fiber is a copolymer with an acrylonitrile content of 81wt%. The viscosity-average molecular weight is 100,000, the content of the third monomer sodium propylene sulfonate in the acrylic fiber is 1.5wt%, the mass concentration of the solvent in the acrylic fiber spinning solution is 90%, the solvent is dimethyl sulfoxide, and the spinneret extrudes The temperature is 30°C, the speed is 10m / s, the coagulation bath is composed of water and N,N-dimethylformamide, the mass concentration of N,N-dimethylformamide in the coagulation bath is 40%, the water bath The stretching temperature is 98°C, and the stretching ratio is 15;

[0054] (2) bath immersion: the acrylic fiber bath is immer...

Embodiment 3

[0058] A kind of preparation method of antibacterial acrylic fiber, its step is as follows:

[0059] (1) Preparation of acrylic fiber: the acrylic fiber is extruded through the spinneret, coagulated at 17°C, stretched in a water bath and washed at 89°C to obtain the acrylic fiber, wherein the acrylic fiber is a copolymer with an acrylonitrile content of 88wt%. The viscosity-average molecular weight is 61,000, the content of the third monomer sodium methacrylate sulfonate in the acrylic fiber is 1.0wt%, the mass concentration of the solvent in the acrylic fiber spinning solution is 80%, the solvent is N-methylmorpholine, and the spinning The temperature of head extrusion is 50°C, the velocity is 7.5m / s, the solidified coagulation bath is composed of water and dimethylamine, the mass concentration of dimethylamine in the coagulation bath is 22.5%, the temperature of water bath stretching is 79°C, The stretching factor is 8;

[0060] (2) Bath immersion: acrylic fiber bath is imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com