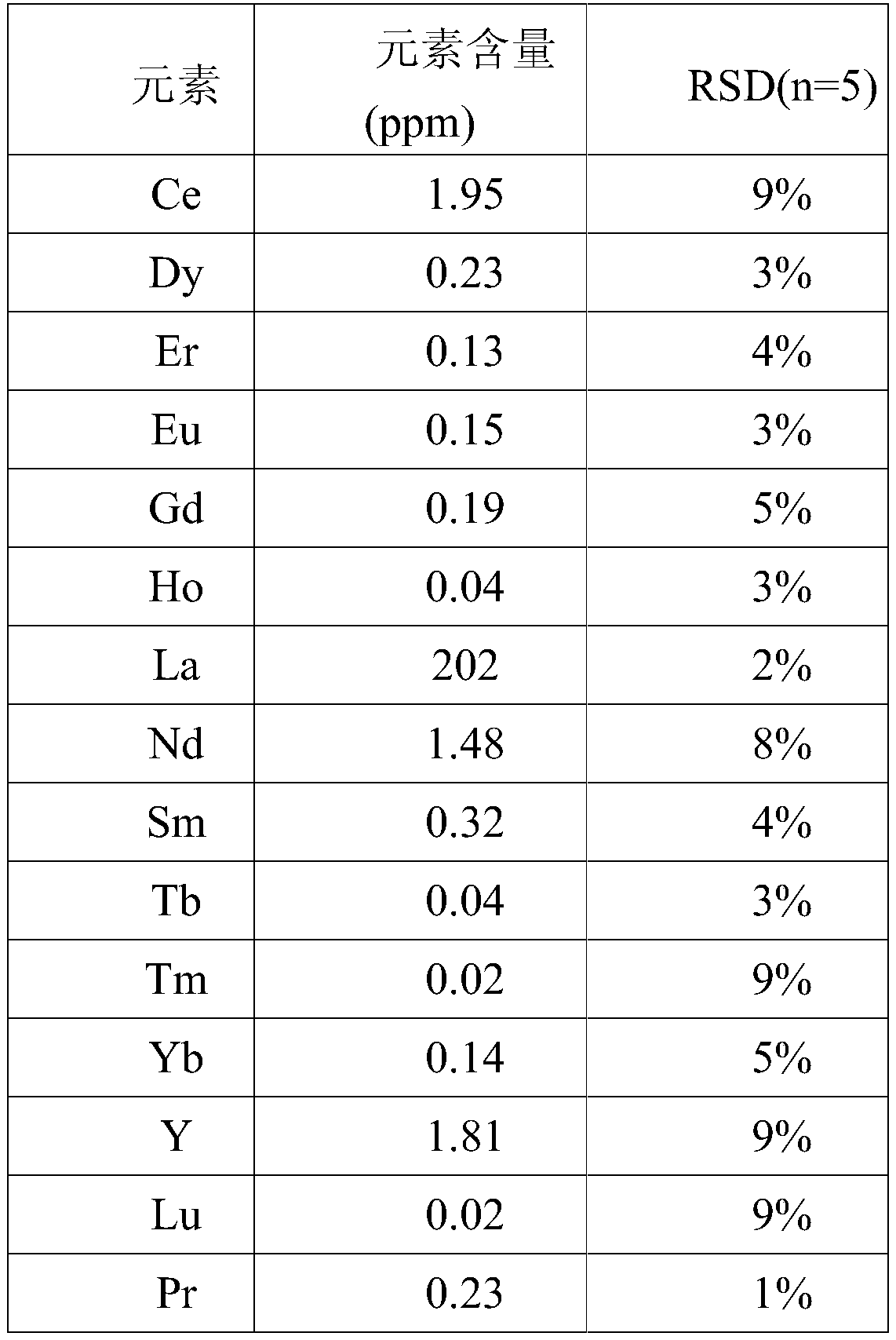

A kind of analysis method of rare earth element content in thorium tetrafluoride

An analytical method and technology of thorium tetrafluoride, which is applied in the field of chemical detection, can solve the problems of many spectral interference, long analysis process and high total dissolved solid content, achieve mild reaction conditions, solve the effect of matrix effect and reduce interference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of sample solution

[0023] Weigh 0.1000g of thorium tetrafluoride powder (accurate to 0.0001g), put it in a 60mL polytetrafluoroethylene tank with a cover, add 1.5g of analytically pure ammonium carbonate and 3mL of high-purity water. Put the polytetrafluoroethylene tank on the electrothermal digestion instrument and heat it at 80°C for 4 hours, the sample is dissolved and clarified, and then removed after cooling.

[0024] Transfer the clarified liquid into a 15mL plastic centrifuge tube, add 1mL of hydrogen peroxide into the plastic centrifuge tube, shake the solution, add hot water at about 60°C to increase the solution to about 12mL.

[0025] Place the above-mentioned plastic centrifuge tube in a water temperature of 60° C. to sonicate until there are basically no bubbles, place it on a centrifuge for 5 minutes, and transfer the water phase to a polytetrafluoroethylene beaker. Place the polytetrafluoroethylene beaker on an electric heating plate an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com