Preparation method and application of sunflower seed husk activated carbon

A sunflower seed shell and activated carbon technology, applied in the field of activated carbon, can solve the problems of high cost, difficult zinc chloride recovery, poor adsorption effect, etc., and achieve the effects of convenient operation, good treatment effect and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

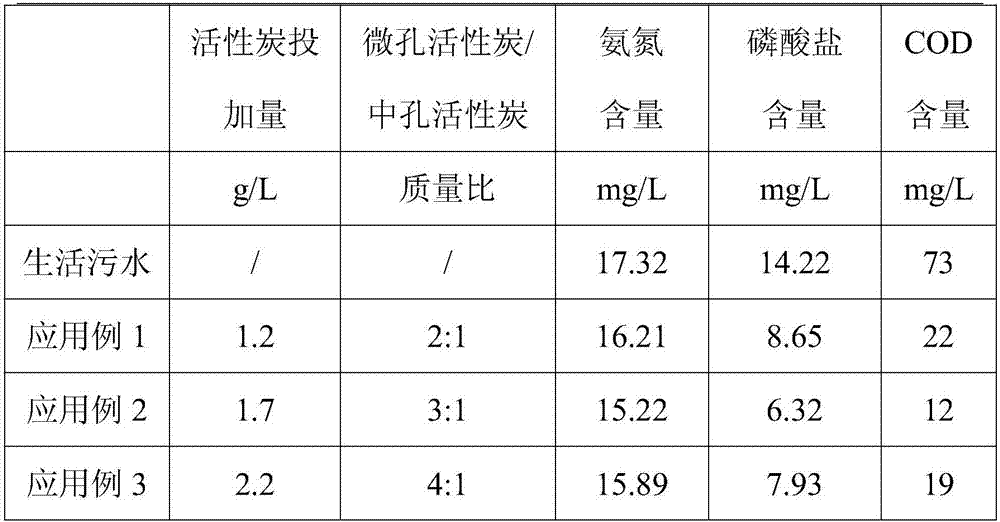

Examples

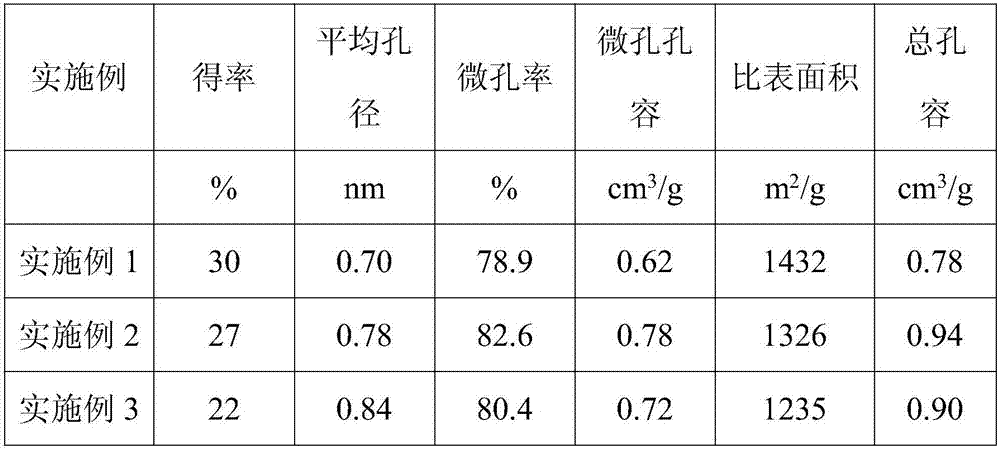

Embodiment 1

[0026] A preparation method of sunflower seed shell activated carbon, comprising the following steps:

[0027] (1) Washing, drying, pulverizing and sieving the sunflower seed husks, the particle size obtained by sieving is 0.5-1mm;

[0028] (2) Mix the crushed sunflower seed hulls with a certain concentration of phosphoric acid according to a certain liquid-solid ratio, place it for 10-12 hours after fully stirring, and then activate it in a vertical tube furnace for 2-4 hours, with a heating rate of 4-8 °C / min, the activation temperature is 550°C, the activation atmosphere condition is 100mL / min of water vapor, the concentration of phosphoric acid is 45%, and the liquid-solid ratio is 1:1;

[0029] (3) Take it out and cool it, wash it with 1% dilute hydrochloric acid or hot water, then wash it with distilled water until the pH value is 5-7, dry it at 110-120°C, grind it, and sieve it with a 200-mesh sieve to obtain the activated carbon product .

Embodiment 2

[0031] A preparation method of sunflower seed shell activated carbon, comprising the following steps:

[0032] (1) Washing, drying, pulverizing and sieving the sunflower seed husks, the particle size obtained by sieving is 0.5-1mm;

[0033] (2) Mix the crushed sunflower seed hulls with a certain concentration of phosphoric acid according to a certain liquid-solid ratio, place it for 10-12 hours after fully stirring, and then activate it in a vertical tube furnace for 2-4 hours, with a heating rate of 4-8 °C / min, the activation temperature is 600°C, the activation atmosphere is 100mL / min of water vapor, the concentration of phosphoric acid is 50%, and the liquid-solid ratio is 1.25:1;

[0034] (3) Take it out and cool it, wash it with 1% dilute hydrochloric acid or hot water, then wash it with distilled water until the pH value is 5-7, dry it at 110-120°C, grind it, and sieve it with a 200-mesh sieve to obtain the activated carbon product .

[0035] Example 1

[0036] A pre...

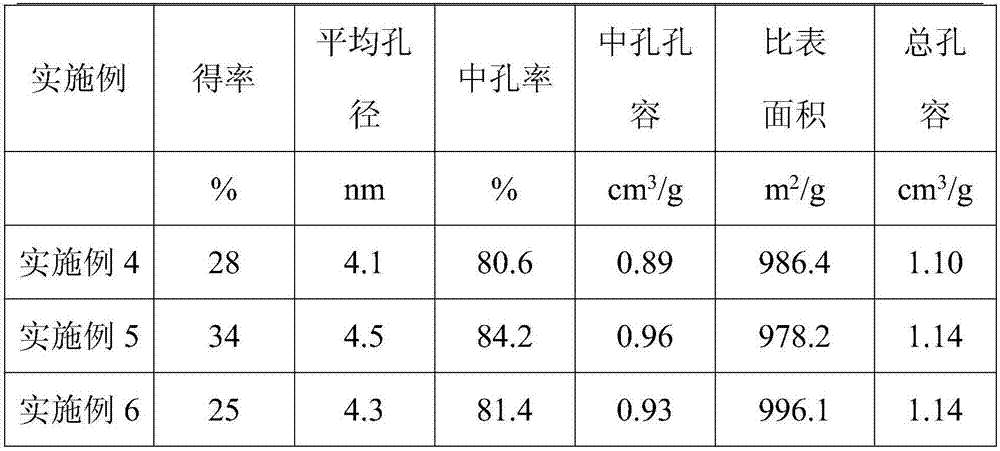

Embodiment 4

[0041] A preparation method of sunflower seed shell activated carbon, comprising the following steps:

[0042] (1) Washing, drying, pulverizing and sieving the sunflower seed husks, the particle size obtained by sieving is 0.5-1mm;

[0043](2) Mix the crushed sunflower seed hulls with a certain concentration of phosphoric acid according to a certain liquid-solid ratio, place it for 10-12 hours after fully stirring, and then activate it in a vertical tube furnace for 2-4 hours, with a heating rate of 4-8 °C / min, the activation temperature is 450°C, the activation atmosphere is 100mL / min of water vapor, the concentration of phosphoric acid is 35%, and the liquid-solid ratio is 1.5:1;

[0044] (3) Take it out and cool it, wash it with 1% dilute hydrochloric acid or hot water, then wash it with distilled water until the pH value is 5-7, dry it at 110-120°C, grind it, and sieve it with a 200-mesh sieve to obtain the activated carbon product .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com