Fibrous membrane for aeration and alga type micro-nano aeration biological membrane component for in situ river control

A nano-aeration and fiber membrane technology, applied in water aeration, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of consumption of dissolved oxygen, insignificant effect, and damage to water body functions, so as to improve contact surface area, increase oxygen mass transfer efficiency, and reduce harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A fiber membrane for aeration, one end of the fiber membrane for aeration is a sealing end, the other end is an open end, and the sealing end is specifically made by the following method:

[0040] (1) Insert one end of the hollow fiber membrane into solution A to a depth of 10 mm, and take it out after solution A fills the inserted end of the hollow fiber membrane.

[0041] In other embodiments, the insertion depth of one end of the hollow fiber membrane into the solution A can be selected between 10-15 mm. Generally, the inserted end of the hollow fiber membrane can be filled when the time for inserting solution A is 30-35s.

[0042] (2) Then put the end of the hollow fiber membrane filled with solution A into solution B and react at 31°C for 2.5 hours. After the reaction, dry at 55°C for 45 minutes to complete the sealing end.

[0043] In other embodiments, the above reaction temperature can be selected between 28-45°C, the reaction time can be selected between 1-8 hou...

Embodiment 2

[0048] In the present embodiment, specifically adopt the fibrous membrane for aeration made in embodiment 1 to make the seaweed formula micro-nano aerated biofilm module.

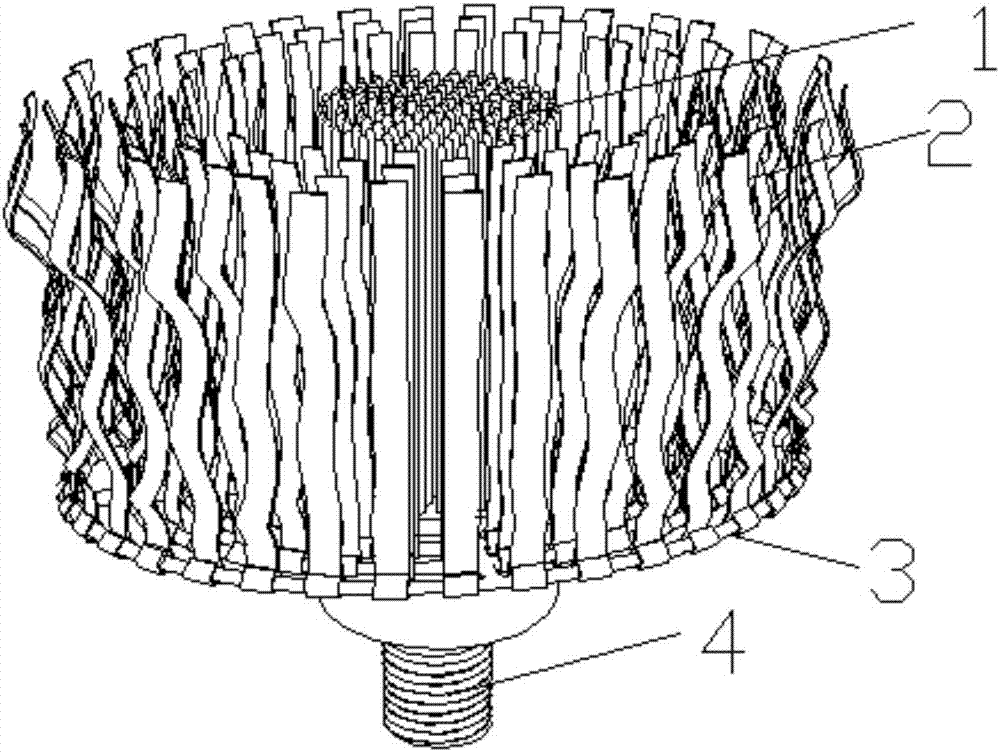

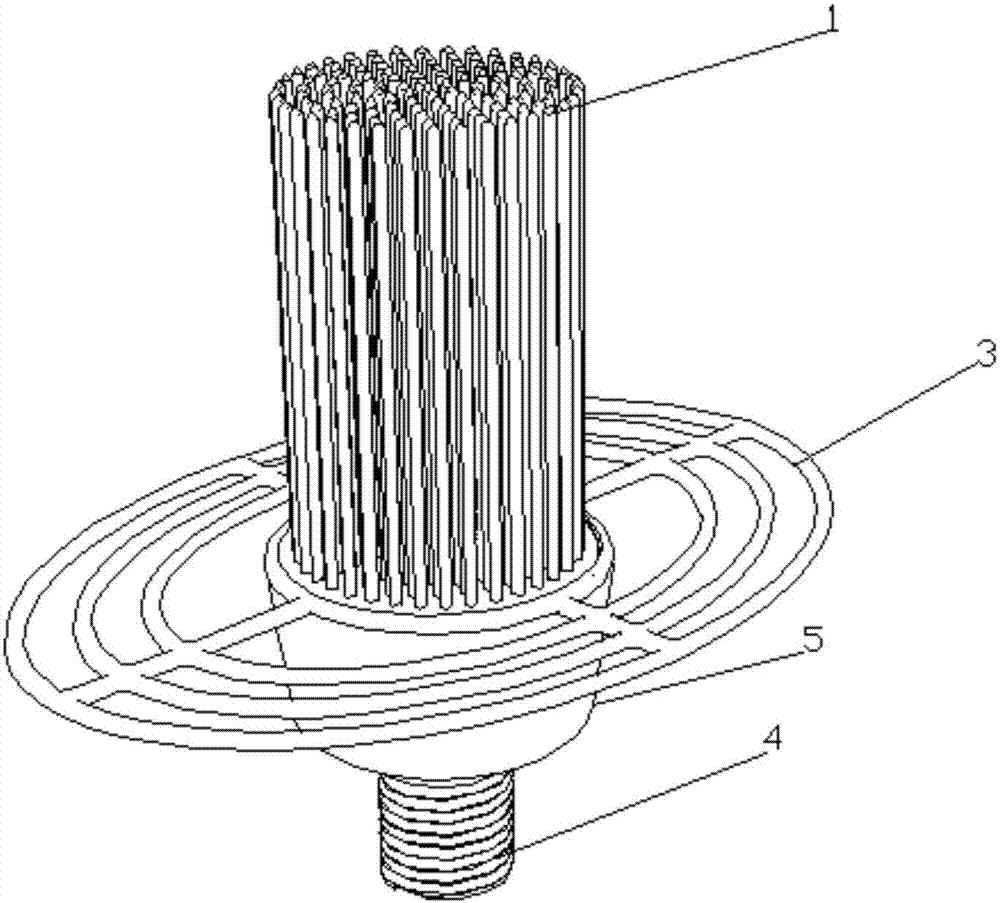

[0049] see Figure 1-Figure 4 , the micro-nano aerated biofilm assembly includes an aerated membrane unit, a biofilm carrier 2 and a terminal.

[0050] The aeration membrane unit comprises a packaging sleeve 6 and a fiber membrane bundle composed of several aeration fiber membranes 1 fixed on the packaging sleeve, and the aeration fiber membranes 1 are fixed on the packaging sleeve 6 through the open end. The aeration membrane unit is fixedly arranged on the end through the packaging sleeve 6.

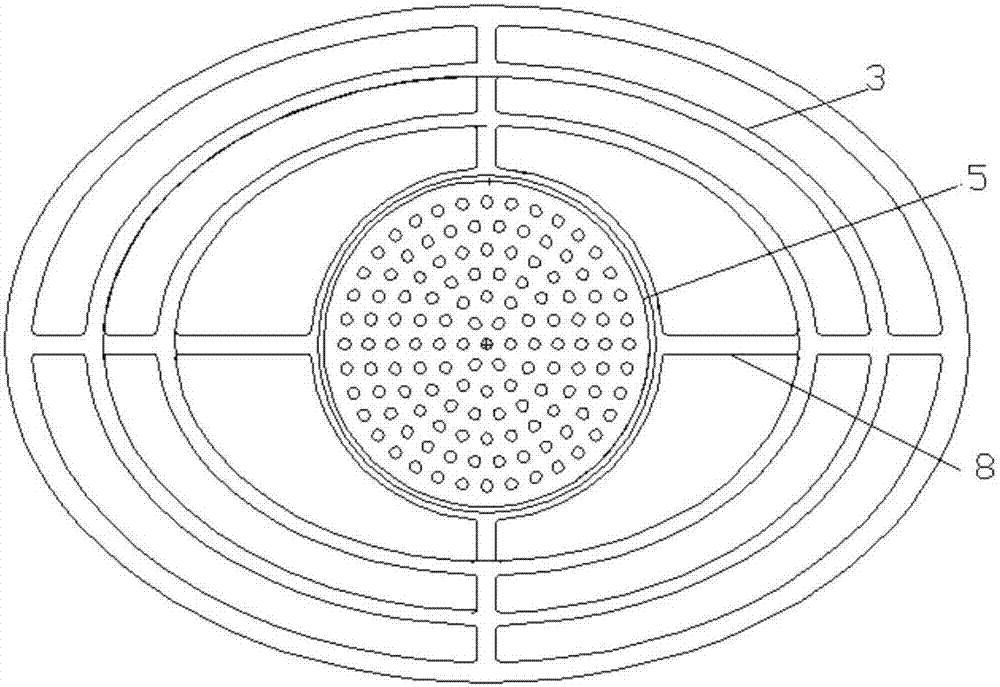

[0051] The end includes a membrane unit fixing part 5 for fixing the aeration membrane unit, a mounting part 4 formed by extending from one end of the membrane unit fixing part 5, and three oval carrier frames 3 for fixing the biofilm carrier 2.

[0052] The membrane unit fixing part 5 is cylindrical, and an inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com