Kraft paper

A kraft cardboard and kraft technology, applied in the field of papermaking, can solve the problems of peeling off the surface layer, prone to blooming in printing, low bonding strength, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

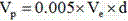

[0024]Pour the rice husk and water into the fermenter at a mass ratio of 1:20, then add distiller's grains 0.4 times the mass of the rice husk, stir and mix with a wooden stick for 20 minutes, seal the fermenter, leave it to stand for 15 days in a closed fermentation, filter, Obtain a filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to a freeze pulverizer, use liquid nitrogen as a grinding medium, freeze and pulverize for 40 min, discharge, and obtain rice husk scraps, and then Rice husk fragments and 15% hydrogen peroxide were poured into the reaction kettle at a mass ratio of 1:80, and stirred at a constant temperature for 6 hours at a temperature of 50°C and a rotation speed of 500r / min, and then filtered to obtain a filter residue, which was used to Wash the filter residue 5 times with deionized water, then transfer the washed filter residue to an oven, and dry it to a constant weight at a temperature of 110°C to o...

example 2

[0026] Pour the rice husk and water into the fermenter at a mass ratio of 1:20, then add distiller's grains 0.4 times the mass of the rice husk, stir and mix with a wooden stick for 20 minutes, seal the fermenter, leave it to stand for 15 days in a closed fermentation, filter, Obtain a filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to a freeze pulverizer, use liquid nitrogen as a grinding medium, freeze and pulverize for 40 min, discharge, and obtain rice husk scraps, and then Rice husk fragments and 15% hydrogen peroxide were poured into the reaction kettle at a mass ratio of 1:80, and stirred at a constant temperature for 6 hours at a temperature of 50°C and a rotation speed of 500r / min, and then filtered to obtain a filter residue, which was used to Wash the filter residue 5 times with deionized water, then transfer the washed filter residue to an oven, and dry it to a constant weight at a temperature of 110°C to ...

example 3

[0028] Pour the rice husk and water into the fermenter at a mass ratio of 1:20, then add distiller's grains 0.4 times the mass of the rice husk, stir and mix with a wooden stick for 20 minutes, seal the fermenter, leave it to stand for 15 days in a closed fermentation, filter, Obtain a filter cake, and wash the filter cake with deionized water for 5 times, then transfer the washed filter cake to a freeze pulverizer, use liquid nitrogen as a grinding medium, freeze and pulverize for 40 min, discharge, and obtain rice husk scraps, and then Rice husk fragments and 15% hydrogen peroxide were poured into the reaction kettle at a mass ratio of 1:80, and stirred at a constant temperature for 6 hours at a temperature of 50°C and a rotation speed of 500r / min, and then filtered to obtain a filter residue, which was used to Wash the filter residue 5 times with deionized water, then transfer the washed filter residue to an oven, and dry it to a constant weight at a temperature of 110°C to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com