A synthetic method of a nanometer HZSM-5 molecular sieve catalyst

A synthesis method, ZSM-5 technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of small-grain ZSM-5 molecular sieve catalysts with long time, low silicon-aluminum ratio, etc. Problems such as serious agglomeration of small grains, to achieve the effect of clear components, easy operation, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

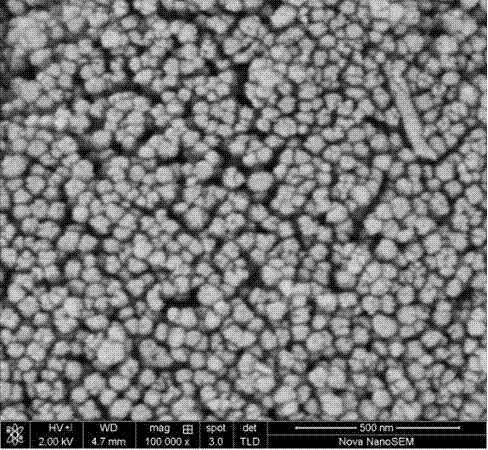

Embodiment 1

[0038] A kind of synthetic method of nanometer HZSM-5 molecular sieve catalyst, take tetraethyl orthosilicate as silicon source, take aluminum nitrate nonahydrate, sodium aluminate or aluminum isopropoxide as aluminum source, use tetrapropyl ammonium hydroxide and tetrapropyl ammonium Ammonium bromide is template agent, is inorganic base with sodium hydroxide, adopts deionized water, and its concrete steps are:

[0039] (1) aging

[0040] A certain amount of templating agent tetrapropyl hydroxide is mixed with a certain amount of deionized water to form a mixture, and silicon source orthosilicate ethyl ester is added dropwise to the mixture, and the molar composition of the synthetic system formed is: 1 di Silicon oxide (SiO 2 ): 1 / 300 Aluminum Oxide (Al 2 o 3 ): 0.10 template agent (TPA): 0.05 sodium oxide (Na 2 O): 8.3 deionized water (H2 O); the resulting synthesis system was heated and stirred at 50° C. to obtain a gel.

[0041] (2) Crystallization

[0042] Dissolve ...

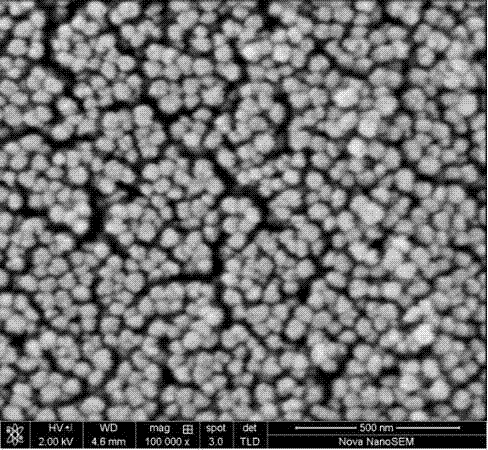

Embodiment 2

[0055] A kind of synthetic method of nanometer HZSM-5 molecular sieve catalyst, take tetraethyl orthosilicate as silicon source, take aluminum nitrate nonahydrate, sodium aluminate or aluminum isopropoxide as aluminum source, use tetrapropyl ammonium hydroxide and tetrapropyl ammonium Ammonium bromide is template agent, is inorganic base with sodium hydroxide, adopts deionized water, and its concrete steps are:

[0056] (1) aging

[0057] Mix a certain amount of templating agents tetrapropylammonium hydroxide and tetrapropylammonium bromide with a certain amount of deionized water to form a mixture, and then add silicon source tetraethyl orthosilicate dropwise into the mixture to form a synthetic The molar composition of the system is: 1 silicon dioxide: 1 / 200 aluminum oxide: 0.25 template agent: 0.05 sodium oxide: 50 deionized water; the obtained synthesis system is heated and stirred at 80° C. to obtain a gel.

[0058] (2) Crystallization

[0059] Dissolve aluminum source ...

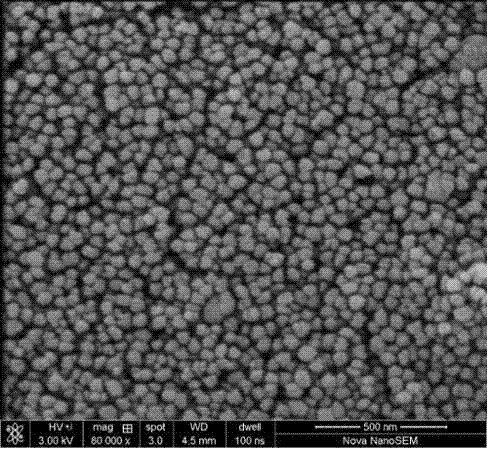

Embodiment 3

[0072] A kind of synthetic method of nanometer HZSM-5 molecular sieve catalyst, take tetraethyl orthosilicate as silicon source, take aluminum nitrate nonahydrate, sodium aluminate or aluminum isopropoxide as aluminum source, use tetrapropyl ammonium hydroxide and tetrapropyl ammonium Ammonium bromide is template agent, is inorganic base with sodium hydroxide, adopts deionized water, and its concrete steps are:

[0073] (1) aging

[0074] Mix a certain amount of templating agents tetrapropylammonium hydroxide and tetrapropylammonium bromide with a certain amount of deionized water to form a mixture, and then add silicon source tetraethyl orthosilicate dropwise into the mixture to form a synthetic The molar composition of the system is: 1 silica: 1 / 100 alumina: 0.35 template: 0.05 sodium oxide: 100 deionized water; the obtained synthesis system is heated and stirred at 100°C to obtain a gel.

[0075] (2) Crystallization

[0076] Dissolve the aluminum source aluminum isopropox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com