Polynitrate/graphene/nanoparticle shaped composite phase-change heat storage material and preparation method thereof

A nanoparticle, composite phase change technology, applied in the direction of heat exchange materials, chemical instruments and methods, can solve the problem of increasing the thermal resistance of heat transfer medium and phase change material, unable to meet the requirements of high temperature heat transfer and heat storage, molten salt The problem of high melting point is to improve the latent heat energy storage of phase change, good thermal stability and chemical stability, and high energy storage density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

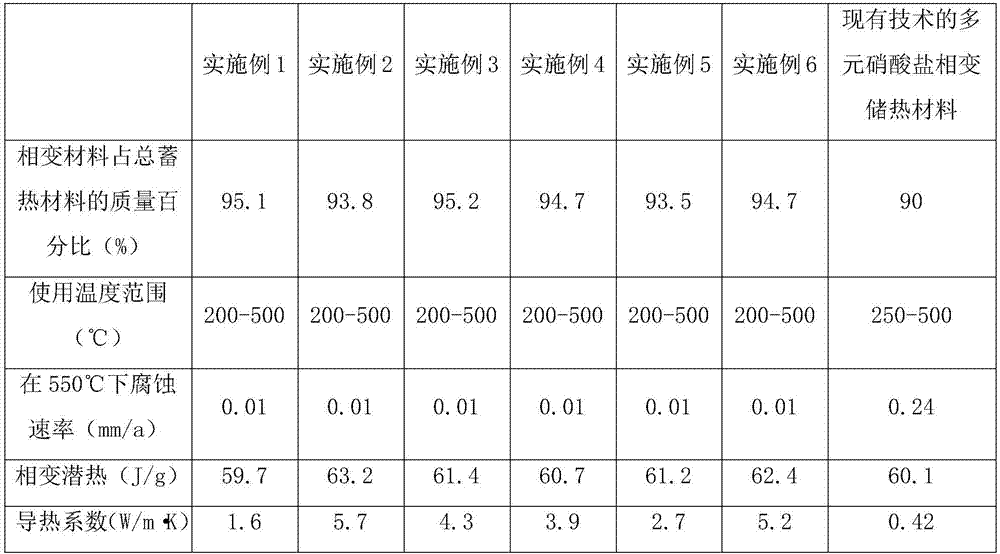

Examples

Embodiment 1

[0027] (1) Add vermicular expanded graphite to the mixed solution of sulfuric acid and phosphoric acid with a volume ratio of 1:8, stir at 0°C at low temperature, add potassium permanganate for oxidation, continue stirring at 50°C for 10h, wash and centrifugally dry , and then reduced by hydrazine hydrate at 180 °C for 10 h to obtain modified network expanded graphene.

[0028] (2) According to the weight ratio of the nitrate mixture and the modified network expanded graphene is 1:0.005, the mixture of calcium nitrate and sodium nitrate with a molar mass ratio of 3:7 is mixed with the modified network expanded graphene, add water Stir to form a suspension, evaporate and dry at 98°C for 3h, place in a muffle furnace for pre-sintering at 280°C for 2h, and cool to room temperature to obtain a granular nitrate-loaded graphene composite.

[0029] (3) After the granular nitrate-loaded graphene composite material and nano-silica ball milled for 1 hour, it was molded under a pressure ...

Embodiment 2

[0031] (1) Add worm-like expanded graphite to a mixed solution of sulfuric acid and phosphoric acid with a volume ratio of 1:9, stir at 5°C at low temperature, add hydrogen peroxide for oxidation, continue stirring at 55°C for 12h, wash and centrifugally dry, Then, it was reduced by hydrazine hydrate at 200°C for 12 hours to obtain modified network-shaped expanded graphene.

[0032] (2) According to the weight ratio of the nitrate mixture and the modified network expanded graphene is 1:0.15, the mixture of calcium nitrate and potassium nitrate with a molar ratio of 6:4 is mixed with the modified network expanded graphene, add water and stir , forming a suspension, evaporated and dried at 102° C. for 3 h, placed in a muffle furnace for pre-sintering at 260° C. for 1.5 h, and cooled to room temperature to obtain a granular graphene composite material loaded with nitrate.

[0033] (3) After the granular nitrate-loaded graphene composite material and nano-titanium dioxide ball mil...

Embodiment 3

[0035] (1) Add worm-like expanded graphite to a mixed solution of sulfuric acid and phosphoric acid with a volume ratio of 1:8.5, stir at 2°C at low temperature, add potassium permanganate for oxidation, continue stirring at 52°C for 11 hours, wash and centrifugally dry , and then reduced by hydrazine hydrate at 190 ° C for 11 h to obtain modified network expanded graphene.

[0036](2) According to the weight ratio of the nitrate mixture and the modified network expanded graphene is 1:0.01, the mixture of calcium nitrate, sodium nitrate and potassium nitrate and the modified network expanded graphite with a molar ratio of 5:3:2 Graphene mixed with water, stirred with water to form a suspension, evaporated and dried at 100°C for 2h, placed in a muffle furnace for pre-sintering at 320°C for 2.5h, cooled to room temperature to obtain a granular nitrate-loaded graphene composite material.

[0037] (3) After the granular nitrate-loaded graphene composite material and nano-silica ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com