Preparation method for graphene/nylon 6 nano composite material

A nanocomposite material and graphene technology, which is applied in the field of preparation of graphene/nylon 6 nanocomposite materials, can solve the problems of unfavorable large-scale preparation of graphene/nylon 6, increase in molecular weight, difficulty in polymerization, etc., and achieve large lateral size , comprehensive performance improvement, and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

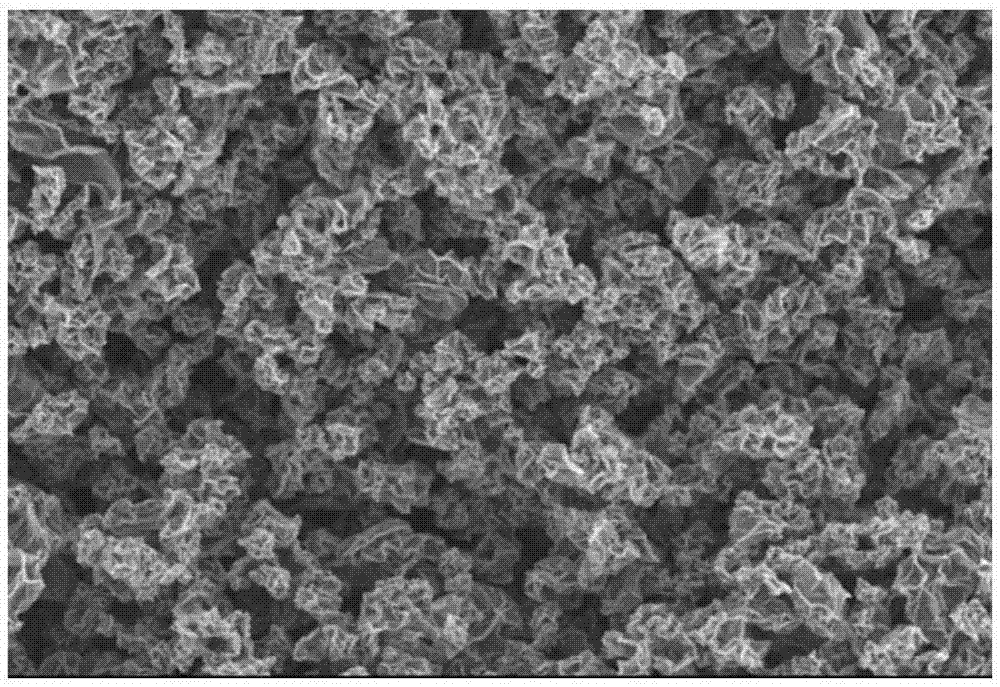

[0022] (1) Dry the single-layer graphene oxide dispersion by atomization drying method to obtain pleated spherical graphene oxide. Oxygen ratio is 5, water content is less than 0.1%;

[0023] (2) Add 3.5 parts by mass of pleated spherical graphene oxide and 2 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and stir and mix at a high speed (400 rpm) at 80° C. to form a dispersion;

[0024] (3) Under the protection of nitrogen, add the above dispersion into the polycondensation reactor, and raise the temperature to 250-270°C, and react at 0.5-1MPa for 3 hours; then react under vacuum for 4 hours to obtain a polymer melt; finally The polymer melt is water-cooled and granulated to obtain a graphene / nylon 6 nanocomposite material.

[0025] Using this material for high-speed spinning, such as Figure 4 Silk rolls shown. Due to the high amount of graphene added, the silk is highly UV resistant and has an extremely low percolation threshold.

[0026] T...

Embodiment 2

[0028] (1) drying the single-layer graphene oxide dispersion by the atomization drying method to obtain pleated spherical graphene oxide, the atomization temperature is 130°C, the size of the graphene oxide sheet is 1 to 20 microns, and the average size is 10 microns, The carbon-oxygen ratio is 4.2, and the moisture content is less than 0.1%;

[0029] (2) Add 2 parts by mass of pleated spherical graphene oxide and 2 parts by mass of deionized water into 100 parts by mass of caprolactam melt, and stir and mix at a high speed (400 rpm) at 80° C. to form a dispersion;

[0030] (3) Under the protection of nitrogen, add the above dispersion into the polycondensation reactor, and raise the temperature to 250-270°C, and react at 0.5-1MPa for 3 hours; then react under vacuum for 4 hours to obtain a polymer melt; finally The polymer melt is water-cooled and granulated to obtain a graphene / nylon 6 nanocomposite material.

[0031] The performance of gained graphene / nylon 6 nanocomposite...

Embodiment 3

[0033] (1) drying the single-layer graphene oxide dispersion by atomization drying method to obtain pleated spherical graphene oxide, the atomization temperature is 130°C, the size of the graphene oxide sheet is 1 to 40 microns, and the average size is 20 microns, The carbon-oxygen ratio is 3.9, and the moisture content is less than 0.1%;

[0034] (2) Add 0.5 parts by mass of pleated spherical graphene oxide and 2 parts by mass of deionized water to 100 parts by mass of caprolactam melt, stir and mix at 80°C at high speed (400rpm) to form a dispersion;

[0035] (3) Under the protection of nitrogen, add the above dispersion into the polycondensation reactor, and raise the temperature to 250-270°C, and react at 0.5-1MPa for 3 hours; then react under vacuum for 4 hours to obtain a polymer melt; finally The polymer melt is water-cooled and granulated to obtain a graphene / nylon 6 nanocomposite material.

[0036] The performance of gained graphene / nylon 6 nanocomposite material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com