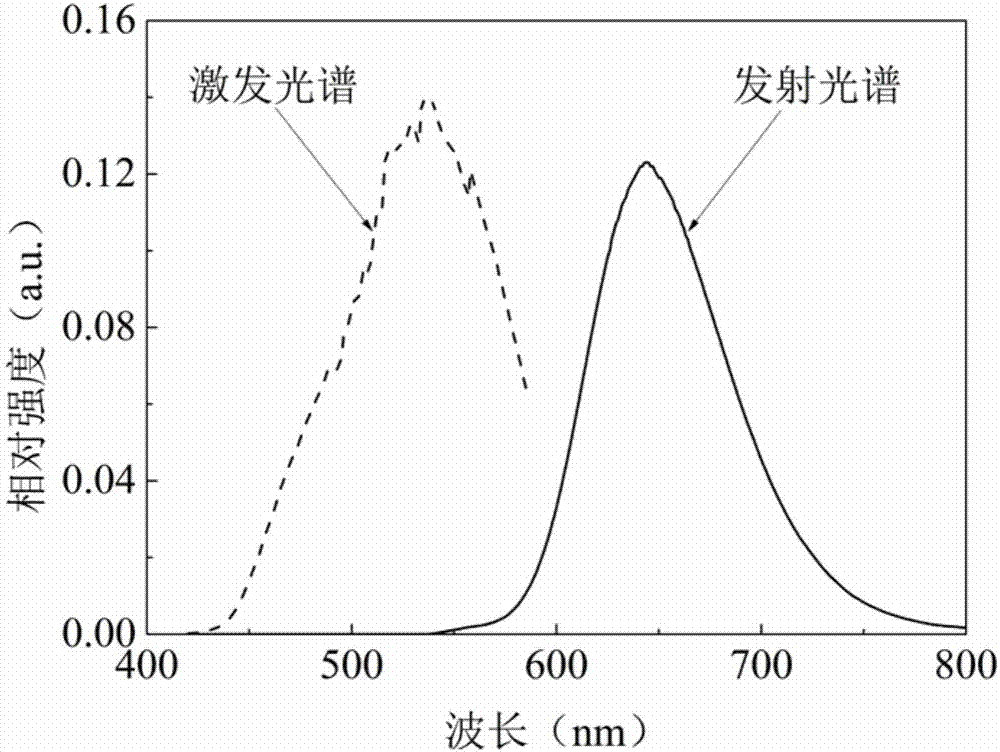

Light conversion agent and preparation method thereof, green light-to-red light greenhouse film and preparation method thereof

A light-transforming agent and thin-film technology, which is applied in botanical equipment and methods, chemical instruments and methods, and luminescent materials, can solve problems such as poor spectral matching, low luminous intensity, and poor photostability, and achieve green light High red light conversion efficiency, high luminous efficiency, not easy to deliquescence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of light conversion agent: first, use high-purity NaCO 3 , MgCO 3 , ZrO 2 and Eu 2 o 3 As raw material, according to the chemical formula Na 2 Mg 0.98 Zr 2 o 6 : 0.02Eu 2+ The stoichiometric ratio of each raw material was weighed, fully ground and mixed in an agate mortar; then the mixture was put into a corundum crucible, and burned in a high-temperature tube furnace with a burning temperature of 1000 °C and a burning time of 6 hours, the sintering atmosphere is a mixture of 5% hydrogen and 95% nitrogen. After the burning is completed, the sample is cooled to room temperature with the furnace, and finally the sintered body is taken out and ball milled, washed and dried to obtain a light-changing agent. .

[0018] Film blowing: Weigh 40 parts of polyethylene resin by weight percentage, 20 parts of light-changing agent, and strengthening agents are respectively 10 parts of glyceryl stearate, 10 parts of tricresol phosphate, 10 parts of phenyl salicyl...

Embodiment 2

[0027] Preparation of light conversion agent: first, use high-purity NaCO 3 , MgCO 3 , ZrO 2 and Eu 2 o 3 As raw material, according to the chemical formula Na 3 Mg 0.499 Zr 2 o 6 : 0.001Eu 2+The stoichiometric ratio of each raw material was weighed, fully ground and mixed in an agate mortar; then the mixture was put into a corundum crucible, and burned in a high-temperature tube furnace with a burning temperature of 1100°C and a burning time of 5 hours, the sintering atmosphere is a mixture of 5% hydrogen and 95% nitrogen. After the burning is completed, the sample is cooled to room temperature with the furnace, and finally the sintered body is taken out and ball milled, washed and dried to obtain a light-changing agent. .

[0028] Film blowing: Weigh 45 parts of polyethylene resin, 30 parts of light-changing agent, 10 parts of glycerol stearate, 5 parts of tricresol phosphate, 5 parts of phenyl salicylate, 5 parts of stearic acid 5 parts of zinc; then mix uniformly...

Embodiment 3

[0030] Preparation of light conversion agent: first, use high-purity NaCO 3 , CaCO 3 , ZrO 2 and Eu 2 o 3 As raw material, according to the chemical formula Na 2 Ca 0.96 Zr 2 o 6 : 0.04Eu 2+ The stoichiometric ratio of each raw material was weighed, fully ground and mixed in an agate mortar; then the mixture was put into a corundum crucible, and burned in a high-temperature tube furnace with a burning temperature of 1200 °C and a burning time of 4 hours, the sintering atmosphere is a mixture of 5% hydrogen and 95% nitrogen. After the burning is completed, the sample is cooled to room temperature with the furnace, and finally the sintered body is taken out and ball milled, washed and dried to obtain a light-changing agent. .

[0031] Film blowing: Weigh 50 parts of polyvinyl chloride resin by weight percentage, 25 parts of light-changing agent, and strengthening agents are respectively 5 parts of glyceryl stearate, 10 parts of tricresol phosphate, 5 parts of phenyl sal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com