Method for preparing carboxylic acid/sulfonic acid mixed waterborne polyurethane with high solid content with solvent-free process

A technology of water-based polyurethane with high solid content, which is applied in the field of water-based polyurethane resin, which can solve the problems of consuming organic solvents and energy, increasing the process flow, and high equipment requirements, and achieves the effects of easy control of the production process, low transportation costs, and high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

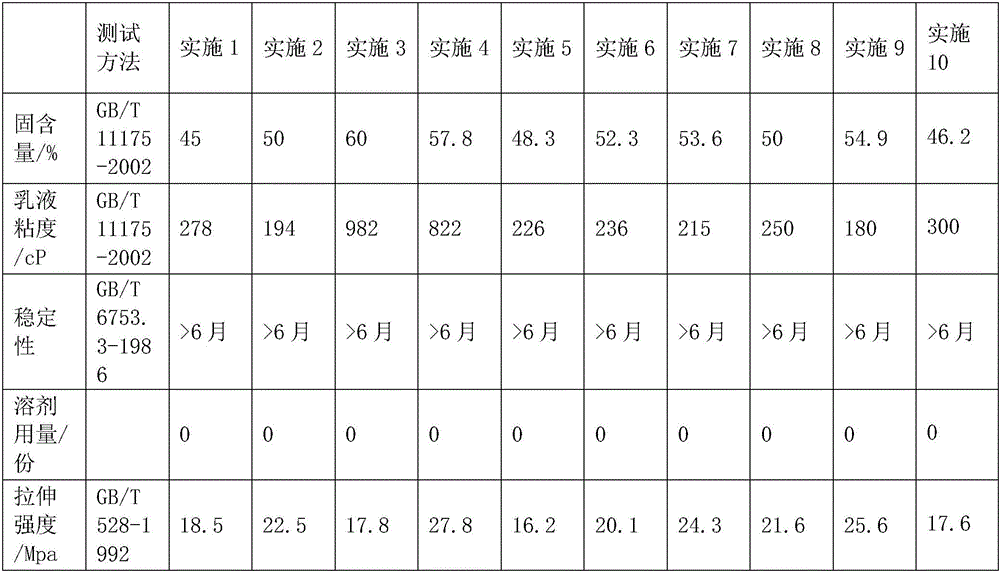

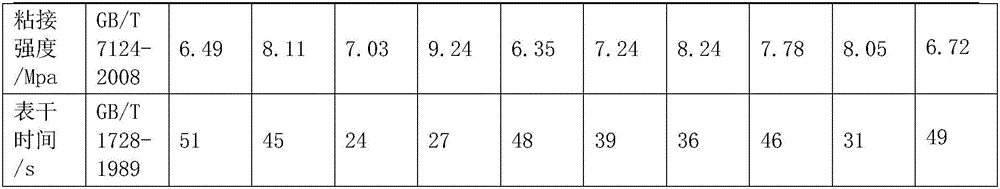

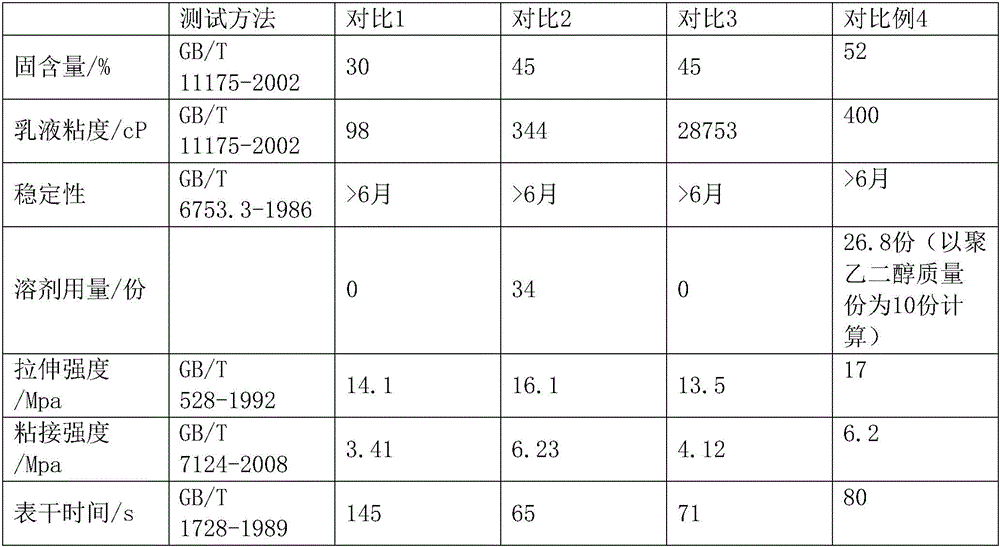

Examples

Embodiment 1

[0024] Embodiment 1: A method for preparing carboxylic acid / sulfonic acid mixed type high-solid-content aqueous polyurethane by a solvent-free method comprises the following steps, and the following parts are in parts by mass:

[0025] Add 10 parts of polybutylene adipate with a relative molecular weight of 1000, 2 parts of butanediol, 20 parts of isophorone diisocyanate and 0.1 part of organic bismuth catalyst into the reaction vessel, and react at 90°C for 2 hours . Then, 1.2 parts of dimethylolpropionic acid was added and reacted at 90° C. for 2 hours. The temperature was lowered to below 60°C, and 0.9 parts of triethylamine was added to react for 45 minutes to obtain an ionomer. Next, with vigorous stirring, 44.1 parts of water were added to the ionomer, which was then stirred for 5 minutes. Finally, 2 parts of sodium ethylenediaminoethanesulfonate were added and reacted for 60 minutes to obtain a carboxylic acid / sulfonic acid mixed type high-solid-content waterborne pol...

Embodiment 2

[0026] Embodiment 2: A method for preparing carboxylic acid / sulfonic acid mixed type high-solid-content aqueous polyurethane by a solvent-free method comprises the following steps, and the following parts are in parts by mass:

[0027] Add 30 parts of polypropylene glycol with relative molecular weight of 3000, 6 parts of hexamethylene diisocyanate and 0.5 part of organic zinc catalyst into the reaction vessel, and react at 70°C for 4 hours. Then add 0.3 parts of dimethylolpropionic acid, and react at 70° C. for 4 hours. The temperature was lowered to below 60°C, and 0.2 parts of triethylamine was added to react for 5 minutes to obtain an ionomer. Next, with vigorous stirring, 39.5 parts of water were added to the ionomer, which was then stirred for 3 minutes. Finally, 3 parts of sodium ethylenediaminoethanesulfonate were added and reacted for 30 minutes to obtain a carboxylic acid / sulfonic acid mixed type high-solid-content water-based polyurethane with a solid content of 50...

Embodiment 3

[0028] Embodiment 3: A method for preparing carboxylic acid / sulfonic acid mixed type high-solid-content aqueous polyurethane by a solvent-free method comprises the following steps, and the following parts are in parts by mass:

[0029] Add 30 parts of polytetrahydrofuran ether diol with a relative molecular weight of 1000, 0.3 parts of ethylene glycol, 0.1 part of trimethylolpropane, and 20 parts of toluene diisocyanate into the reaction vessel, and react at 60° C. for 3 hours. Then add 2.5 parts of dimethylol butyric acid, and react at 60° C. for 4 hours. Cool down to below 60°C, add 2.5 parts of triethanolamine and react for 5 minutes to obtain an ionomer. Next, with vigorous stirring, 38.9 parts of water were added to the ionomer and stirred for 1 minute. Finally, 3 parts of sodium ethylenediaminopropane sulfonate were added and reacted for 5 minutes to obtain a carboxylic acid / sulfonic acid mixed type high-solid content waterborne polyurethane with a solid content of 60%,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com