Method for selectively separating perrhenic acid radical through two-section capacitive deionization process

A capacitive deionization and perrhenate technology, applied in the direction of improving process efficiency, can solve the problems of complex recovery process, increase production cost, poor operating environment, etc., achieve easy adsorption process control, save industrial costs, and reduce implementation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

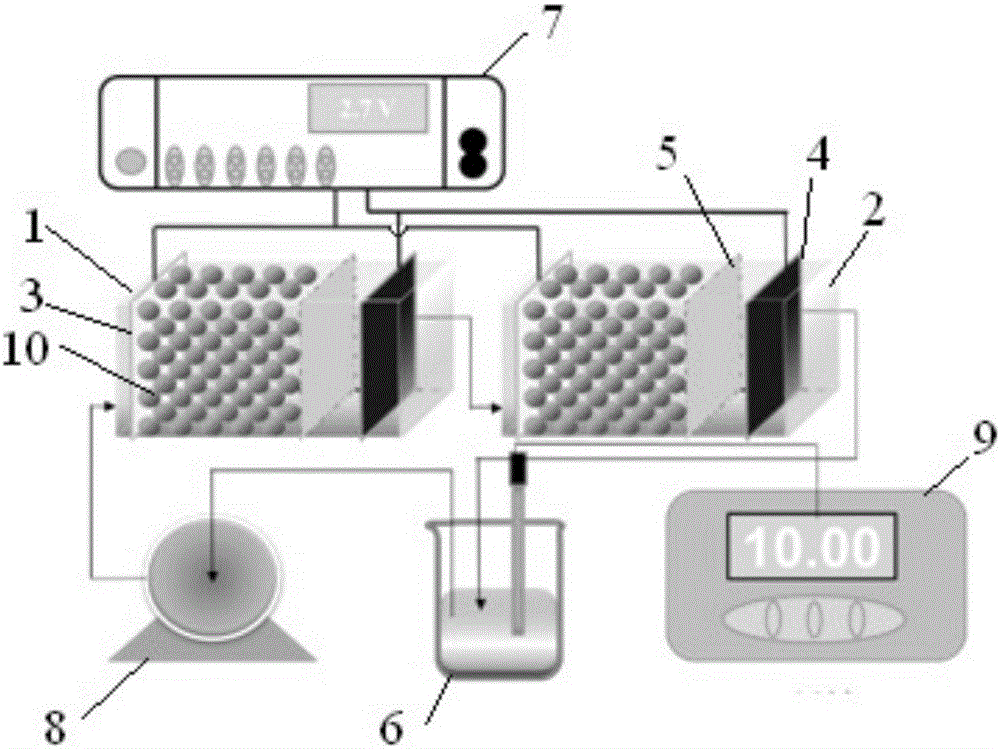

[0032] Apparatus for the selective separation of perrhenate by two-stage capacitive deionization, see image 3 , including the first capacitor 1 and the second capacitor 2, there is a solution channel between the two capacitors; the first capacitor 1 and the second capacitor 2 both use graphite as the anode 3, and the lead plate as the cathode 4; the first A separator 5 is arranged between the anode and the cathode in the segment capacitor and the second segment capacitor, and activated carbon 10 is filled in the anode region.

[0033] The device also includes a DC power supply 7 and a solution container to be adsorbed 6, the positive pole of the power supply is connected to the anode of the two-stage capacitor, the negative electrode is connected to the cathode of the two-stage capacitor, and the solution container to be adsorbed 6 is connected to the inlet of the first stage capacitor through a pipeline and the outlet of the second capacitor, the pipeline is provided with a ...

Embodiment 2

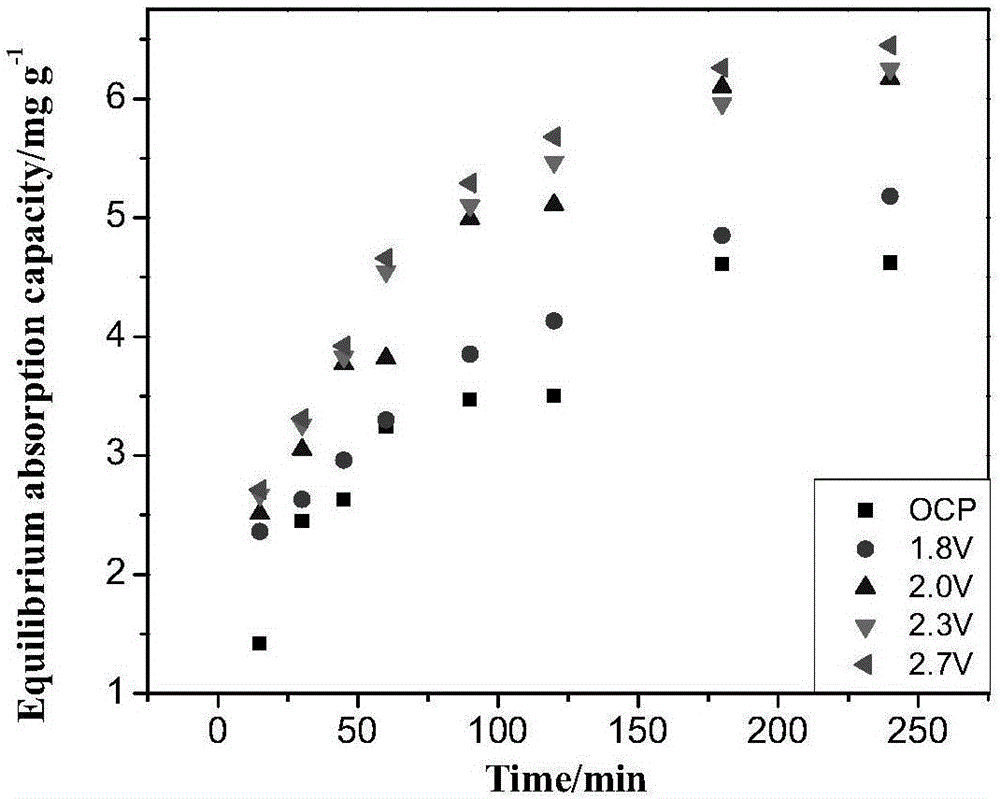

[0039] Embodiment 2: the influence of electric potential on extraction rate

[0040] The potential effect experiment in this embodiment only studies the adsorption effect in the first stage. The device used in this embodiment has only one capacitor, and other settings are the same as in Embodiment 1.

[0041] Fill the anode area of the three-dimensional electrode with 42g of activated carbon. The thickness of the material layer is 3.5cm. The anode uses graphite and the cathode uses lead plates. The size of the cathode and anode plates is 5cm×4.5cm×2mm. Adsorption solution ReO 4 - , SO 4 2- , Cl - and NO 3 - The concentration of the four ions is 100mg L -1 , the pH is controlled to be 10 during the adsorption process, the circulation speed of the peristaltic pump is 55rpm, and the voltage of the control tank is 1.8V, 2.0V, 2.3V, 2.7V ( figure 2 OCP is the open circuit potential), after 4 hours of adsorption, filter the adsorbed solution with a 0.22 μm filter head, u...

Embodiment 3

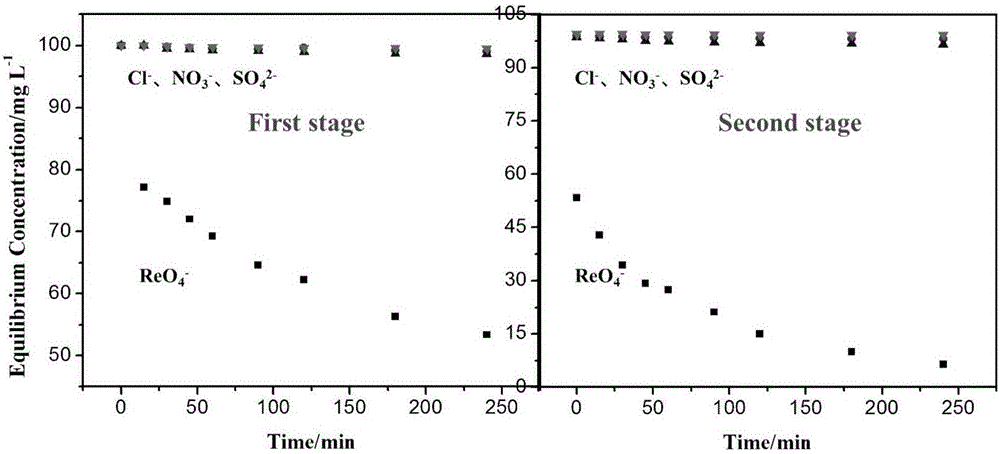

[0043] Embodiment 3: capacitive deionization technology to ReO in actual waste water 4 - extraction of

[0044] Fill the anode area of the three-dimensional electrode with 42g of activated carbon. The thickness of the material layer is 3.5cm. The anode uses graphite and the cathode uses lead plates. The size of the cathode and anode plates is 5cm×4.5cm×2mm. Adsorption solution ReO 4 - The concentration is 7.92mg L -1 , SO 4 2- , Cl - and NO 3 - The concentrations of the three ions are 3953.21 mg L respectively -1 , 120.09 mg L -1 、601.28mg L -1 (The cations in the actual wastewater are mainly Na + and K + ), the pH was controlled to be 10 during the adsorption process, the peristaltic pump circulation speed was 55rpm, and the tank voltage was 2.7V. After adsorption for 4h, the solution after adsorption was filtered with a 0.22μm filter head, and the Re Content analysis, 883 Metrohm ion chromatography for SO 4 2- , Cl - and NO 3 - content analysis.

[0045...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com