Water-ethanol type fire resistant hydraulic fluid for hydraulic system of underground coal mine and preparation method of water-ethanol type fire resistant hydraulic fluid

A technology of hydraulic system and hydraulic fluid, applied in the petroleum industry, lubricating composition, etc., can solve the performance water-glycol type viscosity, flame resistance, oil film bearing capacity, anti-rust performance, lubricating performance, viscosity-temperature index It can achieve the effect of good high temperature thermal stability and high pressure mechanical shear stability, ensuring safe production and efficient operation, and good oil film bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

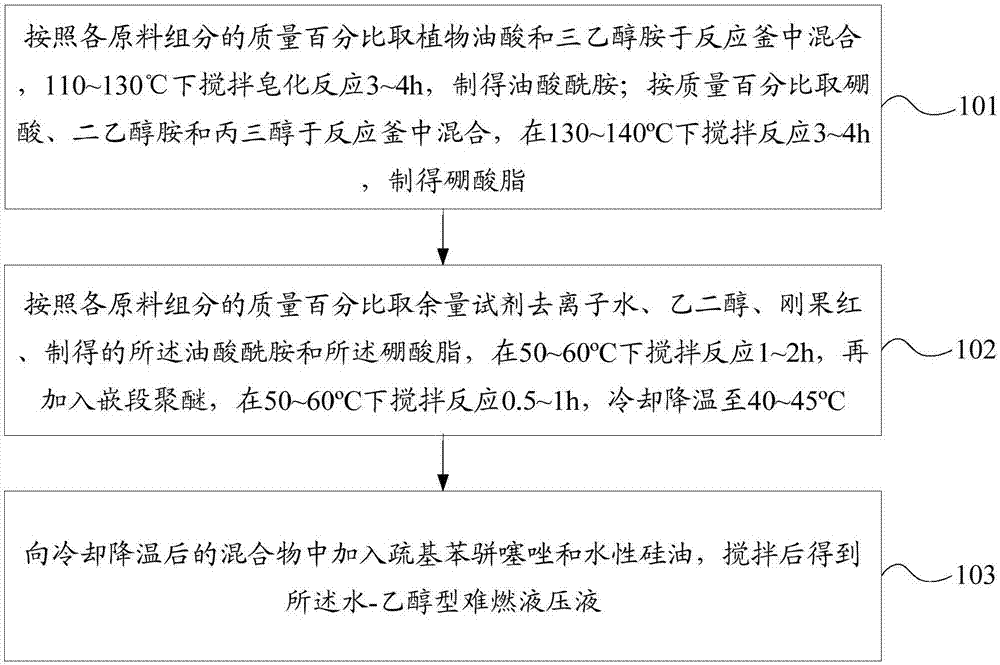

[0038] refer to figure 1 , which shows a flow chart of a method for preparing a water-ethanol type flame retardant hydraulic fluid for a coal mine underground hydraulic system according to an embodiment of the present invention, and the method specifically includes:

[0039] Step 101, mix vegetable oleic acid and triethanolamine in a reaction kettle according to the mass percentage of each raw material component, stir and saponify at 110-130°C for 3-4 hours to obtain oleic acid amide; take boric acid, diethanolamine and triethanolamine according to the mass percentage Mix glycerol in a reaction kettle, stir and react at 130-140°C for 3-4 hours to obtain boric acid ester.

[0040] Step 102, according to the mass percentage of each raw material component, take the remaining reagent deionized water, ethylene glycol, Congo red, the prepared oleic acid amide and boric acid ester, stir and react at 50-60°C for 1-2 hours, and then add Block polyether, stir and react at 50-60°C for 0.5...

Embodiment 1

[0045] According to the mass percentage of each raw material component, take 0.1% vegetable oleic acid and 0.5% triethanolamine and mix them in a reaction kettle, stir and saponify at 110°C for 4 hours to obtain oleic acid amide; take 0.3% boric acid and 0.5% diethanolamine according to the mass percentage Mix it with 1% glycerol in a reaction kettle, stir and react at 130°C for 4 hours to obtain boric acid ester.

[0046] According to the mass percentage of each raw material component, take the remaining reagent deionized water, 40% ethylene glycol, 0.01% Congo red, the prepared oleic acid amide and the prepared boric acid ester, stir and react at 50°C for 2h, and then add 15% block polyether, stirred and reacted at 50°C for 1h, cooled down to 40°C.

[0047] Add 0.5% mercaptobenzothiazole and 0.1% aqueous silicone oil to the cooled mixture, and stir for 30 minutes to obtain the water-ethanol type flame retardant hydraulic fluid.

Embodiment 2

[0049] According to the mass percentage of each raw material component, take 0.2% vegetable oleic acid and 1% triethanolamine and mix them in a reaction kettle, stir and saponify at 130°C for 34 hours to obtain oleic acid amide; take 0.5% boric acid and 0.8% diethanolamine according to the mass percentage Mix it with 1.5% glycerol in a reaction kettle, stir and react at 140°C for 3 hours to obtain boric acid ester.

[0050] According to the mass percentage of each raw material component, take the remaining reagent deionized water, 42% ethylene glycol, 0.02% Congo red, the prepared oleic acid amide and the prepared boric acid ester, stir and react at 60°C for 1h, and then add 17% block polyether, stirred and reacted at 60°C for 0.5h, cooled down to 45°C.

[0051] Add 1% mercaptobenzothiazole and 0.3% aqueous silicone oil to the cooled mixture, and stir for 40 minutes to obtain the water-ethanol type flame retardant hydraulic fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com