Salt tolerant anion exchange membrane chromatography medium, preparation method and uses thereof

An anion exchange membrane and anion technology, applied in the field of separation membranes, to achieve the effects of reducing non-specific adsorption and membrane fouling, low cost, and improving pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

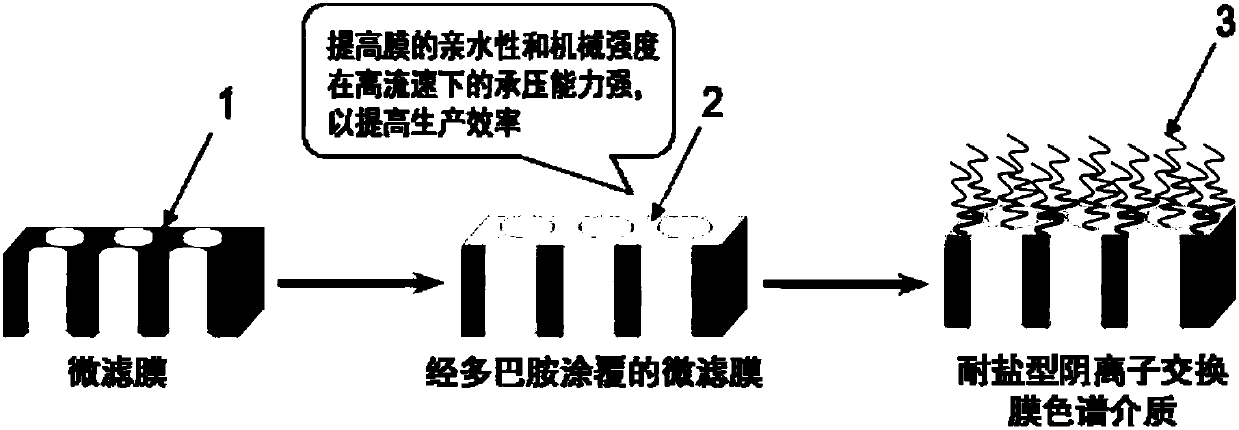

[0052] In the present embodiment, the preparation method of the salt-tolerant anion-exchange membrane chromatographic medium is as follows (the preparation process can be visualized as figure 1 shown in the schematic diagram), specifically include the following steps:

[0053] Add 160 mg of dopamine molecules into 20 mL of 30 mM Tris-HCl buffer (pH 9.5), and at the same time place a piece of polypropylene membrane with a pore size of 2.0 microns ( figure 1 Middle mark 1) Immerse in the dopamine solution, then react in a shaker at 200 rpm at room temperature for 24 hours. After the reaction, the diaphragm was taken out and washed three times with deionized water. Then, the dopamine-coated membrane ( figure 1 Mark 2) Immerse in 2mg / mL agmatine and 0.5mg / mL polyallylamine ( figure 1 Mark 3) Tris-HCl buffer solution (pH = 9.0, 50 mL), react in a shaker at 200 rpm for 24 hours (30°C). After the reaction, rinse the membrane with deionized water. Finally, blow dry with nitrogen ...

Embodiment 2

[0059] In the present embodiment, the preparation method of the salt-tolerant anion-exchange membrane chromatographic medium is as follows (the preparation process can be visualized as figure 1 shown in the schematic diagram), specifically include the following steps:

[0060] Add 0.45mg of dopamine molecules into 45mL of 30mM sodium carbonate-sodium bicarbonate buffer (pH10.5), and at the same time put a piece of polyethersulfone membrane with a pore size of 1.0 micron ( figure 1 Middle mark 1) Immerse in the dopamine solution, then react in a shaker at 400 rpm at room temperature for 1 hour. After the reaction, the diaphragm was taken out and washed three times with deionized water. Then, the dopamine-coated membrane ( figure 1 Mark 2) Immerse in 2.0mg / mL tris(2-aminoethyl)amine and 40.0mg / mL polypropylene amine ( figure 1 The sodium carbonate-sodium bicarbonate buffer solution (pH=11.0, 40mL) marked in 3) was reacted in a shaker at 400 rpm for 1 hour (15°C). After the r...

Embodiment 3

[0066] In this embodiment, the preparation method of the salt-tolerant anion-exchange membrane chromatographic medium (its preparation process can be visualized as figure 1 The shown schematic diagram) specifically includes the following steps:

[0067] Add 90 mg of dopamine molecules into 50 mL of 30 mM Tris-HCl buffer (pH 7.2), and at the same time place a piece of polyvinylidene fluoride membrane with a pore size of 5.0 microns ( figure 1 Middle mark 1) Immerse in the dopamine solution, then react at room temperature for 36 hours with a rotating speed of 20 rpm in a shaker. After the reaction, the diaphragm was taken out and washed three times with deionized water. Then, the dopamine-coated membrane ( figure 1 Mark 2) immersed in 2.5mg / mL agmatine and 0.1mg / mL polyhexamethylene biguanide ( figure 1 The Tris-HCl buffer solution (pH=7.0, 50 mL) indicated in 3) was reacted in a shaker at a speed of 20 rpm for 48 hours (80° C.). After the reaction, rinse the membrane with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com