A preparation method of flexible film based on graphene micro-cylindrical array

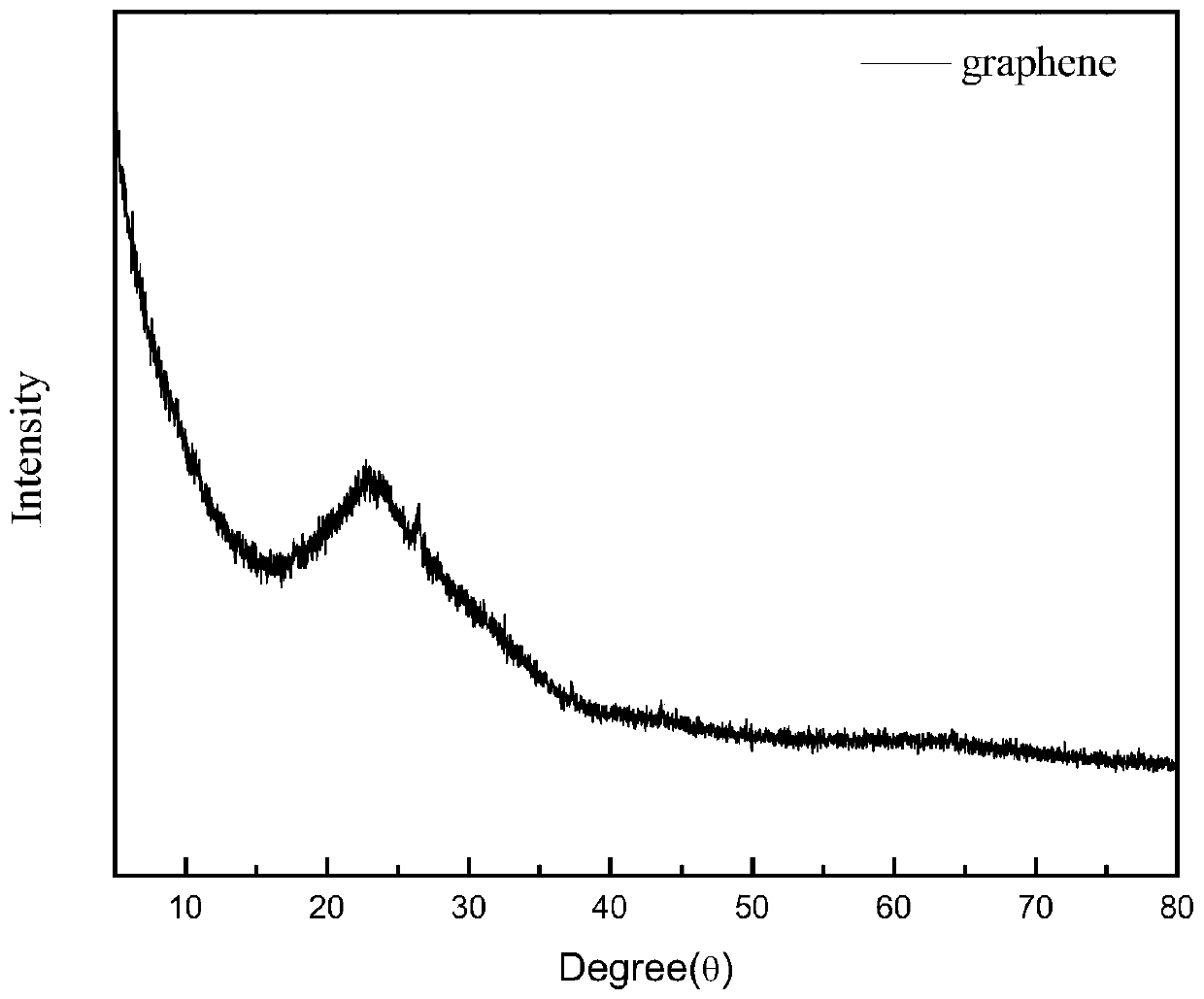

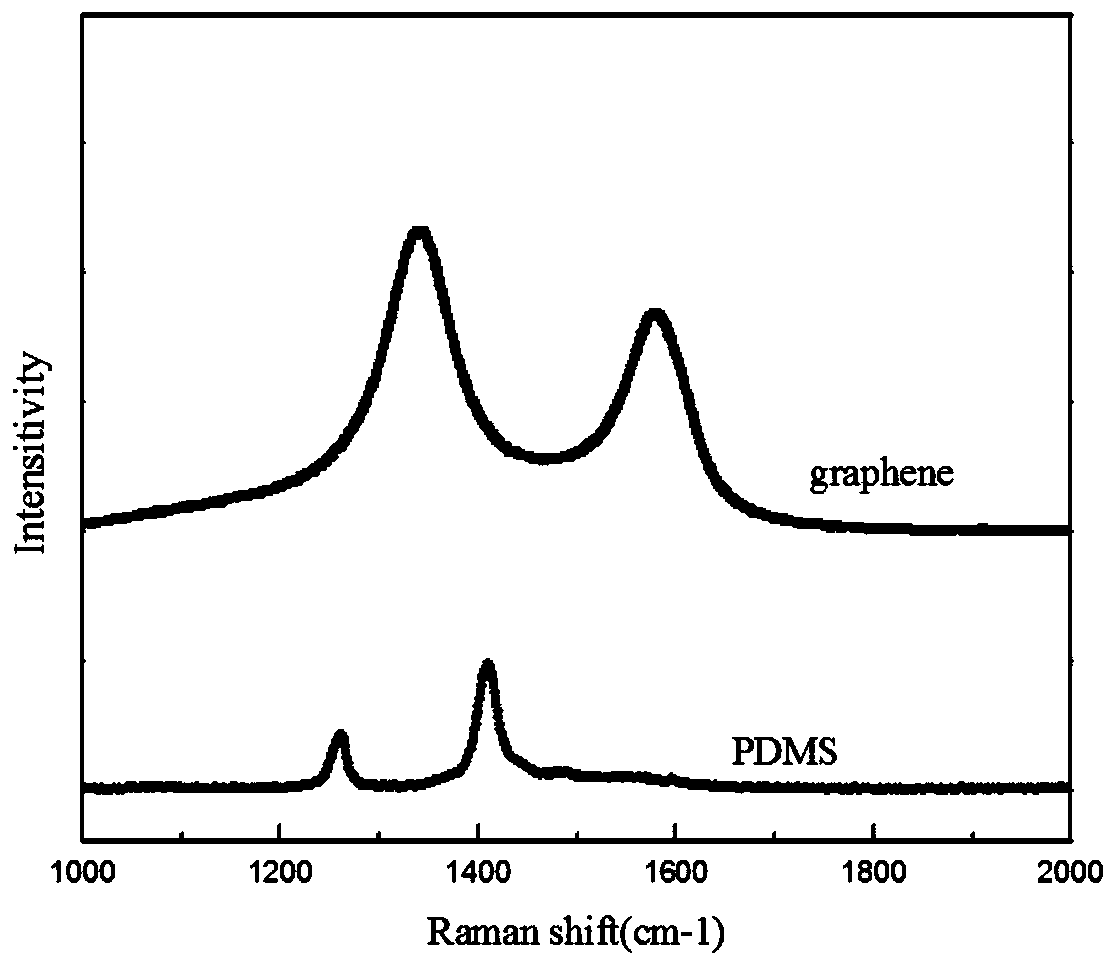

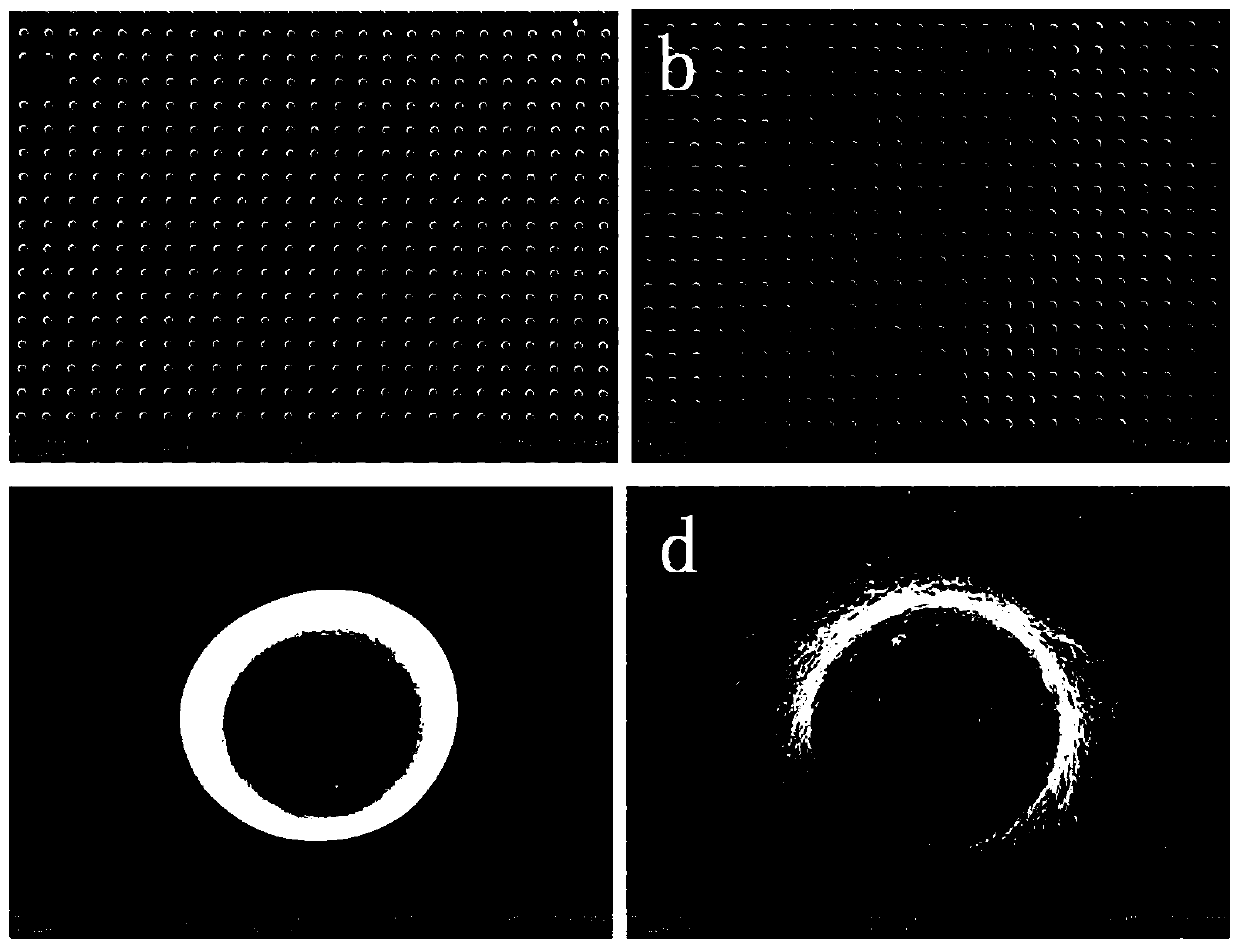

A flexible film, graphene technology, applied in the field of graphene film preparation, advanced graphene-based micro-nano processing film, can solve the problem of difficult to achieve dynamic pressure repeatability, conductivity depends on temperature, electric field, easily affected by external conditions, etc. problems, to achieve the effect of enhancing hydrophilicity and binding force, avoiding photolithography methods, and improving conductivity and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Treat a silicon template (1.5cm*1cm) with a microarray with sulfuric acid and hydrogen peroxide at a volume ratio of 3:1 in a water bath at 90°C for 1 hour, then wash with deionized water and dry.

[0020] (2) Soak the cleaned silicon template in 93wt% n-heptane, 2wt% octadecyltrimethoxysilane and 5wt% ethyl acetate mixed solution for 1h, and seal and isolate the moisture in the air with a parafilm to prevent The long chain of octadecyltrimethoxysilane is hydrolyzed into silica, which blocks the micro-cylindrical template, and then the silicon template is rinsed with n-heptane to remove the trace amount of silica hydrolyzed in the micro-cylindrical array, and finally the silicon template is Dry in an oven at 100°C to 120°C for 1 hour.

[0021] (3) Weigh dimethylsiloxane and crosslinking agent in a beaker according to the mass ratio of 10:1, stir for 20 minutes, remove air bubbles in vacuum, place it upside down on a template with a microarray, and place it in a vacu...

Embodiment 2

[0031] This embodiment aims to study the influence of different plasma oxygen etching times on the properties of the film.

[0032] (1) Treat a silicon template (1.5cm*1cm) with a microcolumn array with sulfuric acid and hydrogen peroxide at a volume ratio of 3:1 in a water bath at 90°C for 1 hour, then wash with deionized water and dry.

[0033] (2) Soak the cleaned silicon template in 93wt% n-heptane, 2wt% octadecyltrimethoxysilane and 5wt% ethyl acetate mixed solution for 1h, and seal and isolate the moisture in the air with a parafilm to prevent The long chain of octadecyltrimethoxysilane is hydrolyzed into silica to block the micro-cylindrical template, and then the silicon template is rinsed with n-heptane to remove the trace amount of silica hydrolyzed in the micro-cylindrical array, and finally the silicon template is Dry in an oven at 100°C to 120°C for 1 hour.

[0034](3) Weigh dimethylsiloxane and crosslinking agent in a beaker according to the mass ratio of 10:1, ...

Embodiment 3

[0042] This example aims to study the influence of different graphene dispensing amounts on film properties.

[0043] (1) Treat a silicon template (1.5cm*1cm) with a microcolumn array with sulfuric acid and hydrogen peroxide at a volume ratio of 3:1 in a water bath at 90°C for 1 hour, then wash with deionized water and dry.

[0044] (2) Soak the cleaned silicon template in 93wt% n-heptane, 2wt% octadecyltrimethoxysilane and 5wt% ethyl acetate mixed solution for 1h, and seal and isolate the moisture in the air with a parafilm to prevent The long chain of octadecyltrimethoxysilane is hydrolyzed into silica, which blocks the micro-cylindrical template, and then the silicon template is rinsed with n-heptane to remove the trace amount of silica hydrolyzed in the micro-cylindrical array, and finally the silicon template is Dry in an oven at 100°C to 120°C for 1 hour.

[0045] (3) Weigh dimethylsiloxane and crosslinking agent in a beaker according to the mass ratio of 10:1, stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com