Sm-Gd-Dy tri-rare-earth ion tantalate and preparation method and application thereof

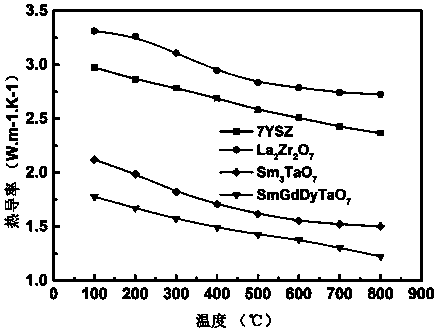

A technology of rare earth ions and tantalate, applied in the field of tantalate, can solve the problems of low temperature, coating failure, high melting point, etc., and achieve the effect of small grain size, less defects such as cracks, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments 1-8.

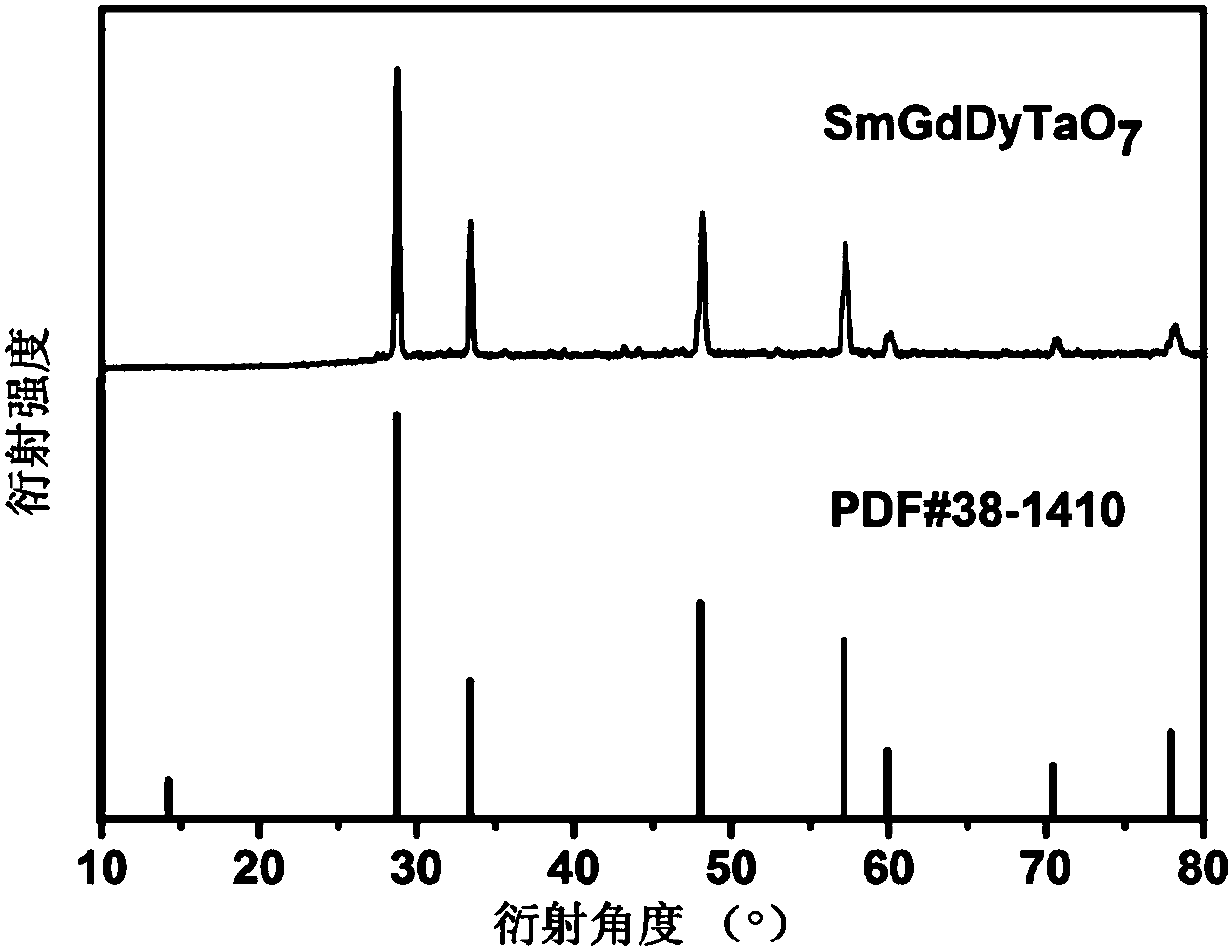

[0028] The Sm-Gd-Dy triple rare earth ion tantalate provided by the present invention has a general chemical formula of Sm a Gd b Dy c TaO 7 , wherein, a+b+c=3, a, b, c=0.8~1.2. In each embodiment, the coefficients of Sm, Gd, and Dy are shown in Table 1 for details.

[0029] The preparation steps of the above-mentioned Sm-Gd-Dy triple rare earth ion tantalate are as follows:

[0030] (1) Take samarium nitrate (Sm(NO 3 ) 3 ), gadolinium nitrate (Gd(NO 3 ) 3 ), dysprosium nitrate (Dy(NO 3 ) 3 ) and tantalum oxalate (Ta 2 (C 2 o 4 ) 5 ), added to citric acid (C 6 h 8 o 7 ), the specific additions of each embodiment are shown in Table 1 (need to be converted into mass when weighing, and in the present invention, the stoichiometric ratio is conveniently expressed so the moles are used for measurement). Incubate at 135...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com