A kind of preparation method of high-performance porous co-mn-o nano sheet material and its obtained material and application

A technology of co-mn-o and nanosheets, which is applied in the preparation and application of high-performance porous Co-Mn-O nanosheets, can solve the rare research and optimization of Co-Mn-O two-dimensional nanosheets, Co- Mn-O two-dimensional nanosheet series research has not been reported and other problems, to achieve the effect of good industrialization prospects, improved electrochemical performance, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

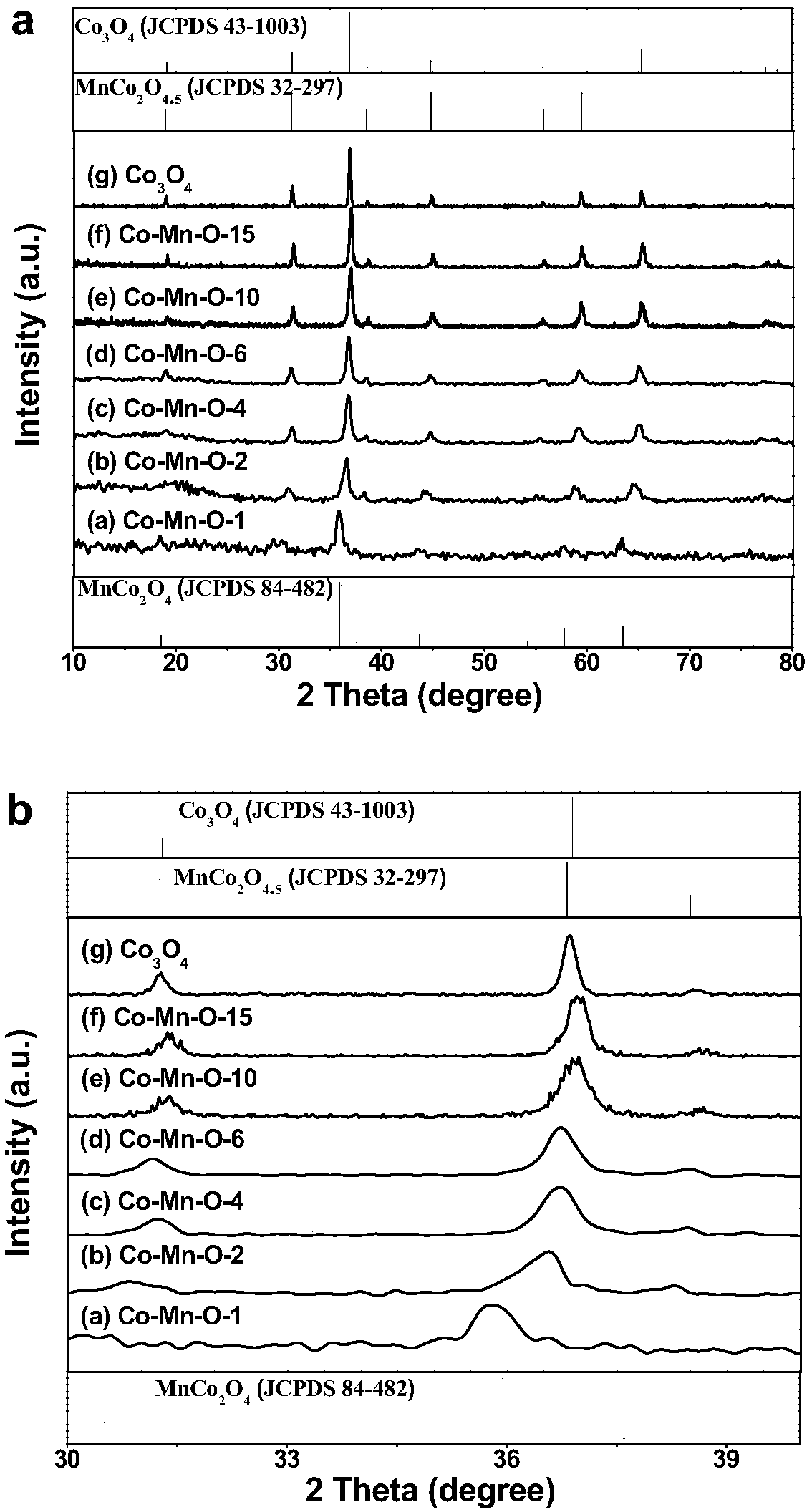

Method used

Image

Examples

Embodiment 1

[0032] 1) Prepare a mixed solution with 13mL absolute ethanol, 13mL ethylene glycol and 1ml water.

[0033] 2) Add 0.2g P-123 to the above mixed solution, and dissolve it evenly by ultrasonic;

[0034] 3) Add 0.0921g C 4 h 6 MnO 4 4H 2 O and 0.09375g C 4 h 6 CoO 4 4H 2 O is dispersed in the above mixed solution (cobalt acetate: manganese acetate molar ratio is 1 / 1), after ultrasonic dissolution is complete, aging for 72h;

[0035] 4) Put the above-mentioned aged solution into a 50mL polytetrafluoroethylene substrate, and put it on the shell of a stainless steel reaction kettle for hydrothermal reaction at 170°C for 5h.

[0036] 5) After collecting, washing and vacuum-drying the material after the hydrothermal reaction, the powder was sintered in a muffle furnace at 600 ° C for 5 h to obtain a black powder, which is a porous Co-Mn-O nanosheet (denoted as Co-Mn -O-1);

[0037]6) Fully grind the dried composite material as the lithium ion electrode negative electrode ma...

Embodiment 2

[0039] Same operation as Example 1, except that the cobalt acetate: the manganese acetate mol ratio is 2 / 1). (Denoted as Co-Mn-O-2)

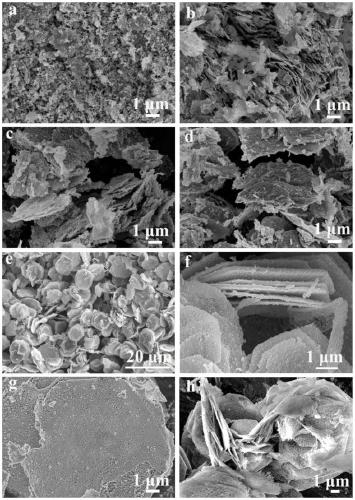

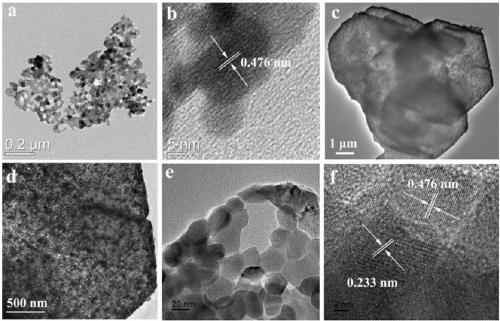

[0040] Adopt TEM to characterize the morphology of the prepared sample in this embodiment, as Figure 4 shown. The Si nanoparticles are evenly and effectively covered by the carbon coating.

Embodiment 3

[0042] Same operation as Example 1, except that cobalt acetate: manganese acetate mol ratio is 4 / 1). (Denoted as Co-Mn-O-4).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com