Green preparation method of N-substituted-L-pyroglutamate

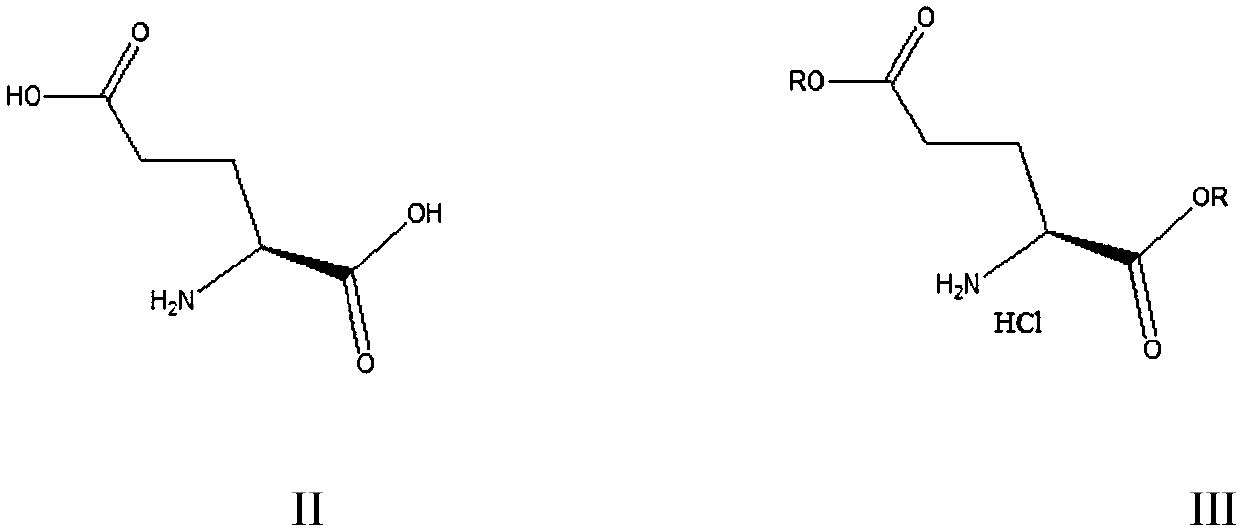

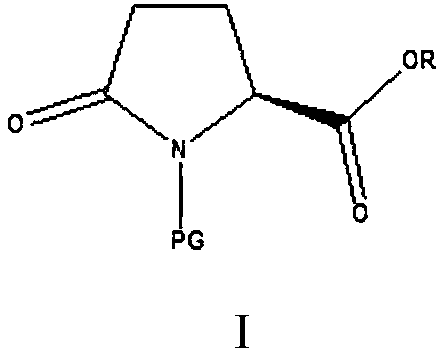

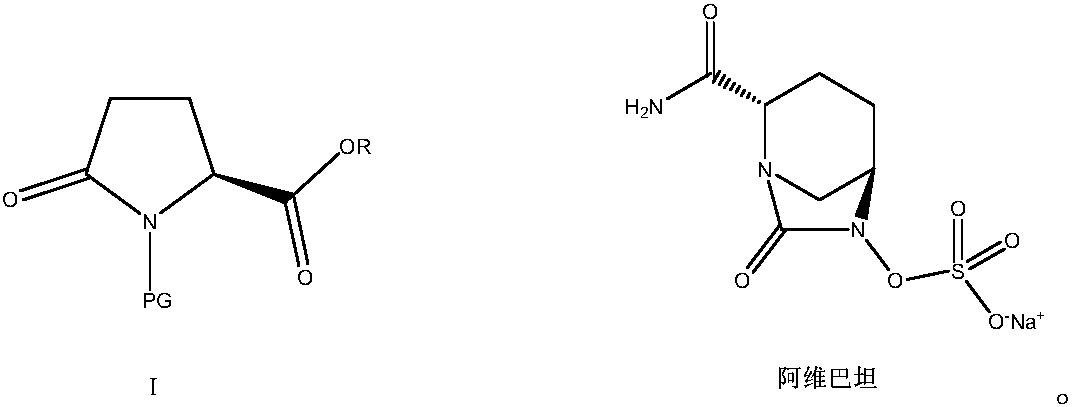

A technology of pyroglutamate and glutamate diester hydrochloride, which is applied in the field of green preparation of N-substituted-L-pyroglutamate, can solve unfavorable green production, cumbersome post-processing, and long process routes and other problems, to achieve the effect of classic reaction type, short process route and high reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: L-glutamic acid dibenzyl ester hydrochloride (Ⅲ 1 ) preparation

[0048] Add 280 grams of benzyl alcohol, 14.7 grams (0.10 moles) of L-glutamic acid, 30.0 grams (0.25 mol) thionyl chloride, heated, reacted at 80-85°C for 5 hours, cooled to 20-25°C, replaced hydrogen chloride gas in the system with nitrogen, and after 30 minutes of replacement, recovered excess thionyl chloride and benzyl alcohol by distillation, and then Add 120 g of methyl tert-butyl ether to the residue, beat, filter, and dry to obtain 35.9 g of white solid L-dibenzyl glutamate hydrochloride with a liquid phase purity of 99.8% and a yield of 98.7%.

Embodiment 2

[0049] Embodiment 2: L-glutamic acid dibenzyl ester hydrochloride (Ⅲ 1 ) preparation

[0050]Add 280 grams of benzyl alcohol, 14.7 grams (0.10 moles) of L-glutamic acid, 30.0 grams (0.15 mol) diphosgene, heated, reacted at 70-75°C for 6 hours, cooled to 20-25°C, and replaced the hydrogen chloride gas in the system with nitrogen for 30 minutes. Recover excessive diphosgene and benzyl alcohol by distillation, then add 120 grams of methyl tert-butyl ether to the residue, make a slurry, filter, and dry to obtain 35.5 grams of white solid L-dibenzyl glutamate hydrochloride, liquid phase The purity is 99.7%, and the yield is 97.6%.

Embodiment 3

[0051] Embodiment 3: L-glutamic acid diethyl ester hydrochloride (Ⅲ 2 ) preparation

[0052] Add 300 grams of ethanol, 14.7 grams (0.10 moles) of L-glutamic acid, 25.0 grams (0.08 moles) ) Triphosgene, heating, reacting at 70-75° C. for 5 hours, cooling to 20-25° C., replacing hydrogen chloride gas in the system with nitrogen, and replacing it for 30 minutes. Recover excess triphosgene and ethanol by distillation, then add 100 grams of methyl tert-butyl ether to the residue, make a slurry, filter, and dry to obtain 23.5 grams of white solid L-diethyl glutamate hydrochloride with a liquid phase purity of 99.7 %, the yield is 98.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com