Preparation method of carbon-coated ferroferric oxide nanometer core-shell microspheres for lithium battery

A carbon coating technology of ferric oxide and ferric tetroxide, applied in the field of electrochemical materials, can solve problems such as electrochemical performance attenuation, volume change, etc., to prevent unfavorable oxidation, uniform particle size distribution, and improve material conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

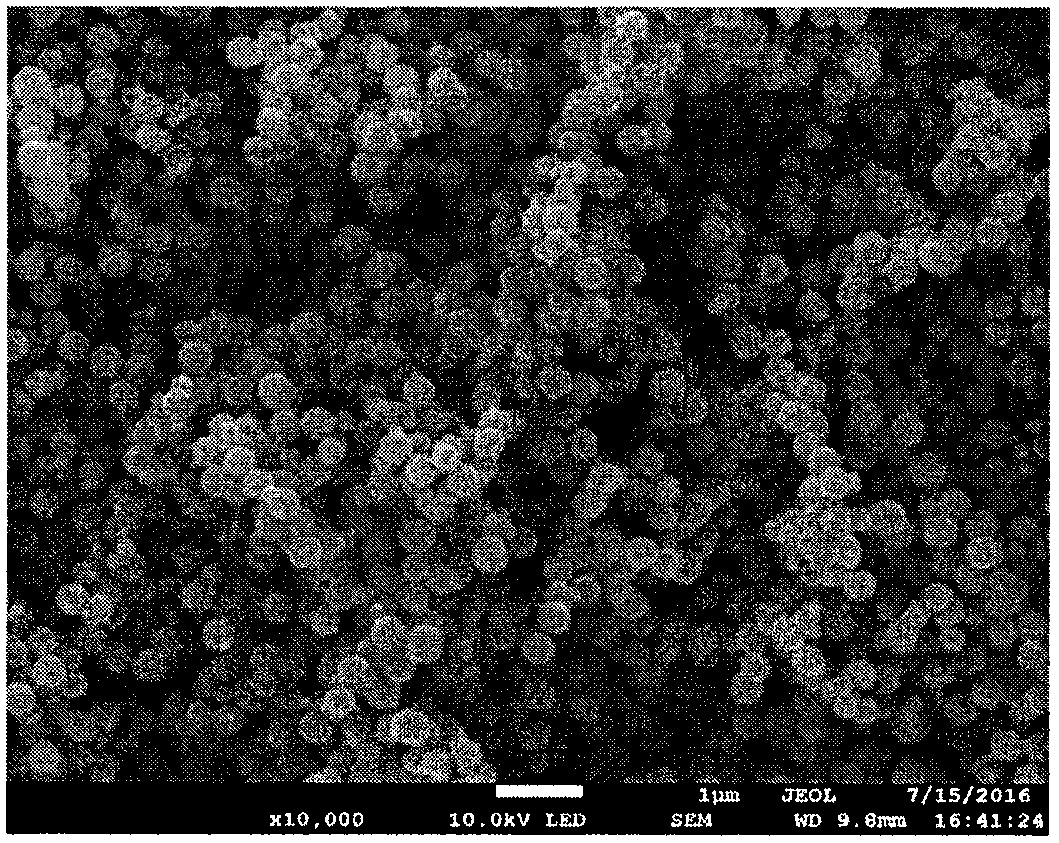

[0031] Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 (O) 4.8g as iron source, join in 60mL ethylene glycol (EG), carry out ultrasonic dispersion 20min; Then, weigh 9.6g of anhydrous sodium acetate, wherein 3 ·6H 2 O) the ratio with anhydrous sodium acetate is 1: 2, joins above-mentioned solution, magnetically stirs 30min; The above-mentioned solution is transferred in the reactor of polytetrafluoroethylene liner, reacts 24h at 180 ℃; Treat that reaction finishes, After naturally cooling to room temperature, the reaction product was washed by centrifugation with distilled water and absolute ethanol in sequence; and then dried in vacuum at 60°C for 12 hours to obtain nano-ferric oxide, and its scanning electron microscope picture is as follows figure 1 shown.

[0032] Weigh 0.025g of phenolic resin as a carbon source, add a little absolute ethanol dropwise, and dissolve by ultrasonic or stirring; 3 o 4 5% of the mass, continue to ultrasonically disperse for 20 minutes; af...

Embodiment 2

[0035] Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 (O) 4.8g as iron source, join in 80mL ethylene glycol (EG), carry out ultrasonic dispersion 20min; Then, take by weighing 4.8g of anhydrous sodium acetate, wherein 3 ·6H 2 O) the ratio with anhydrous sodium acetate is 1: 1, joins above-mentioned solution, magnetically stirs 30min; The above-mentioned solution is transferred in the reactor of polytetrafluoroethylene liner, reacts 16h at 200 ℃; Treat that reaction finishes, After naturally cooling to room temperature, the reaction liquid was successively washed by centrifugation with distilled water and absolute ethanol; and then dried in vacuum at 60° C. for 12 hours to obtain nanometer ferric oxide.

[0036] Weigh 0.05g of epoxy resin as a carbon source, add a little toluene dropwise, and dissolve by ultrasonic or stirring; 3 o 4 10% of the mass, continue to ultrasonically disperse for 20 minutes; after that, pour the mixture into an agate mortar, use toluene as solven...

Embodiment 3

[0039] Weigh ferric chloride hexahydrate (FeCl 3 ·6H 2 (O) 4.8g is used as iron source, join in 100mL ethylene glycol (EG), carry out ultrasonic dispersion 20min; 3 ·6H 2O) and the ratio of anhydrous sodium acetate is 2: 1, joins above-mentioned solution, magnetically stirs 30min; The above-mentioned solution is transferred in the reactor of polytetrafluoroethylene lining, reacts 12h at 220 ℃; Treat that reaction finishes, After naturally cooling to room temperature, the reaction solution was successively washed by centrifugation with distilled water and absolute ethanol, and then dried in vacuum at 60° C. for 12 hours to obtain nanometer ferric oxide.

[0040] Weigh 0.1g of Copna resin as a carbon source, add a little tetrahydrofuran dropwise, and dissolve by ultrasonication or stirring; 3 o 4 20% of the mass, continue to ultrasonically disperse for 20 minutes; after that, pour the mixture into an agate mortar, use tetrahydrofuran as a solvent, add a little to grind until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com