Nitro-compound fertilizer and preparation method thereof

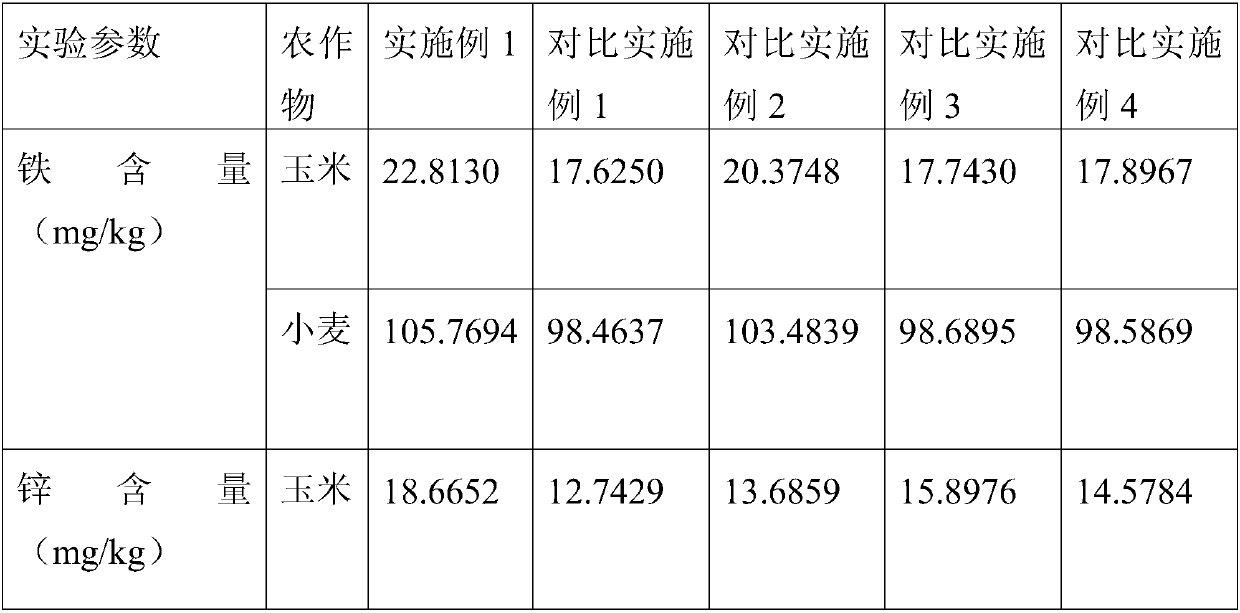

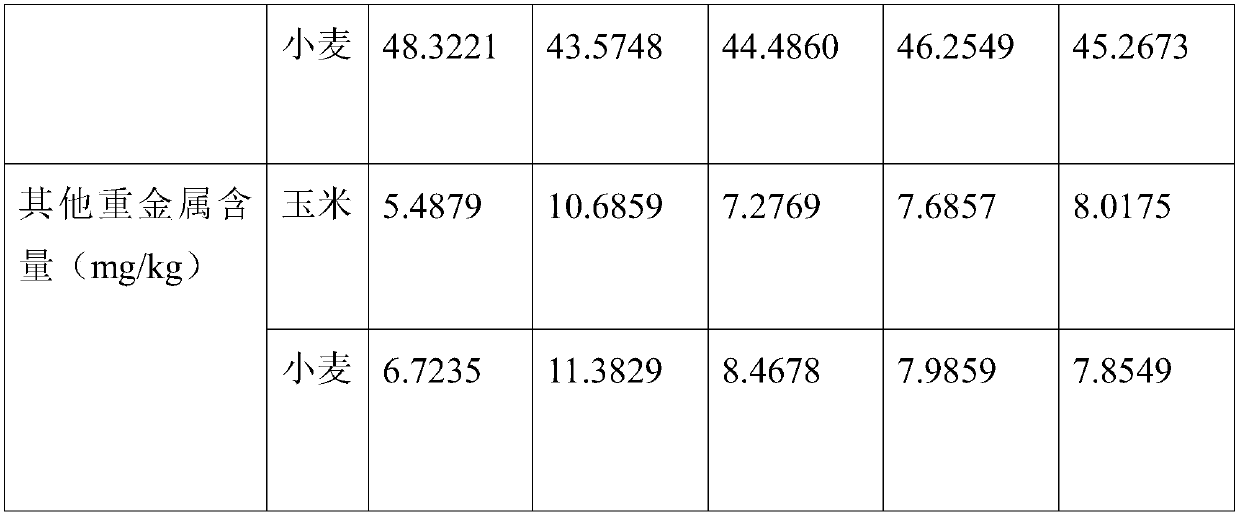

A technology of nitro compound fertilizer and phosphate fertilizer, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of reducing the quality and quality of crops, affecting human nutrition and health, increasing harmful heavy metals, etc., to promote absorption, increase iron content, The effect of increasing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A nitro compound fertilizer, the nitro compound fertilizer comprises the following components in weight percentage: 36.882% of ammonium nitrate phosphate fertilizer, 28% of potash fertilizer, 32% of phosphate fertilizer, silicate polymer coated sodium citrate and silicate polymer Material coated sodium malate 2.5%, bentonite 0.5%, boron 0.06%, manganese 0.03%, molybdenum 0.008%, copper 0.02%. Wherein, the ammonium nitrate phosphate fertilizer is ammonium nitrate fertilizer and nitrate phosphate fertilizer.

[0027] The preparation method of described nitro compound fertilizer comprises the steps:

[0028] 1) Preparation of polymer-coated iron-zinc absorption enhancer: add sodium citrate and sodium malate into the coating machine, spray the silicate polymer on the surface of the mixture of sodium citrate and sodium malate under mixing and stirring, Stir in the drum of the coating machine for 30s, and discharge;

[0029] 2) Equip raw materials in proportion;

[0030] 3...

Embodiment 2

[0032] A nitro compound fertilizer, the nitro compound fertilizer comprises the following components in weight percentage: 27.436% of ammonium nitrate phosphate fertilizer, 40% of potash fertilizer, 30% of phosphate fertilizer, silicate polymer coated sodium citrate and silicate polymer Material coated sodium malate 1.5%, bentonite 0.8%, boron 0.2%, manganese 0.05%, molybdenum 0.006%, copper 0.008%. Wherein, the ammonium nitrate phosphate fertilizer is ammonium nitrate fertilizer and nitrate phosphate fertilizer.

[0033] The preparation method of described nitro compound fertilizer comprises the steps:

[0034] 1) Preparation of polymer-coated iron-zinc absorption enhancer: add sodium citrate and sodium malate into the coating machine, spray the silicate polymer on the surface of the mixture of sodium citrate and sodium malate under mixing and stirring, Stir in the drum of the coating machine for 10s, and discharge;

[0035] 2) Equip raw materials in proportion;

[0036] 3...

Embodiment 3

[0038] A kind of nitro compound fertilizer, the nitro compound fertilizer comprises the following components by weight percentage: 36.93% of ammonium nitrate phosphate fertilizer, 18% of potash fertilizer, 40% of phosphate fertilizer, silicate polymer coated sodium citrate and silicate polymer Material coated sodium malate 3.5%, bentonite 1.2%, boron 0.3%, manganese 0.05%, molybdenum 0.01%, copper 0.01%. Wherein, the ammonium nitrate phosphate fertilizer is ammonium nitrate fertilizer and nitrate phosphate fertilizer.

[0039] The preparation method of described nitro compound fertilizer comprises the steps:

[0040] 1) Preparation of polymer-coated iron-zinc absorption enhancer: add sodium citrate and sodium malate into the coating machine, spray the silicate polymer on the surface of the mixture of sodium citrate and sodium malate under mixing and stirring, Stir in the coating machine drum for 50s and discharge;

[0041] 2) Equip raw materials in proportion;

[0042] 3) A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com