Preparation method of 2-bromo-5-iodobenzoic acid

A technology of bromobenzoic acid and iodobenzoic acid, applied in the field of preparation of 2-bromo-5-iodobenzoic acid, can solve problems such as only total yield, unsuitable for industrialized production, etc., achieves simple steps, good market prospects, and reaction mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

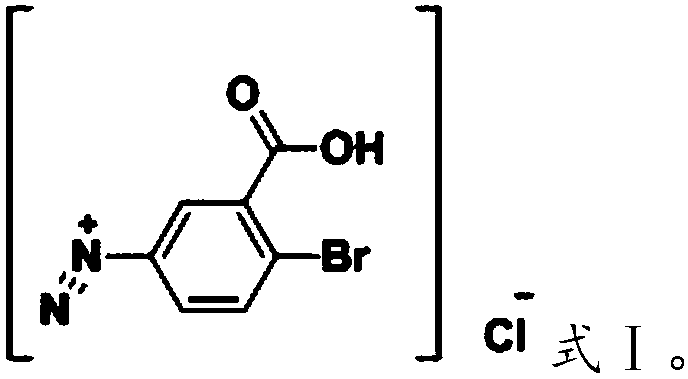

[0028] The invention provides a kind of preparation method of 2-bromo-5-iodobenzoic acid, comprises the steps:

[0029] (1) 5-amino-2-bromobenzoic acid, inorganic acid, organic solvent and water are mixed to obtain 5-amino-2-bromobenzoic acid mixed solution;

[0030] (2) adding the nitrite aqueous solution dropwise to the 5-amino-2-bromobenzoic acid mixed solution to undergo a diazonium reaction to obtain a diazonium salt system;

[0031] (3) Add the iodide aqueous solution dropwise to the diazonium salt system to generate iodine reaction;

[0032] (4) After the iodination reaction is completed, an aqueous solution of sodium bisulfite is added to the system for quenching to obtain 2-bromo-5-iodobenzoic acid.

[0033] The invention mixes 5-amino-2-bromobenzoic acid, inorganic acid, organic solvent and water to obtain 5-amino-2-bromobenzoic acid mixed liquid. In the present invention, the mass ratio of the 5-amino-2-bromobenzoic acid, inorganic acid, organic solvent and water ...

Embodiment 1

[0058] Add 200.0 g of m-aminobenzoic acid and 760.0 g of N,N-dimethylformamide in turn into the reaction flask. Stir and cool down to 0°C; slowly add 273.0g of N-bromosuccinimide, control the temperature at 0°C, and complete the addition within 1h. Incubate at 0°C for 1 h. After the reaction was completed, 3.4Kg of water was added dropwise to quench the reaction. After the drop was completed, stirring was continued at 10° C. for 1 h. Filter and wash the filter cake once with 400.0 g of water. The wet product was dried at 60°C for 10 h to obtain 261.0 g of 5-amino-2-bromobenzoic acid with a product yield of 82.8%.

[0059] The obtained 5-amino-2-bromobenzoic acid is carried out to NMR and mass spectrometry detection, the results are as follows:

[0060] 1 H NMR (400MHz, DMSO) δ13.05(s), 7.26(d, J=8.6Hz), 6.94(d, J=2.8Hz), 6.59(dd, J=8.6, 2.8Hz), 5.52(s) .

[0061] MS calcd for C 7 h 7 BrNO 2 (M+H) + :217,found:217.

[0062] NMR and mass spectrometric detection result...

Embodiment 2

[0069] 20.0Kg of m-aminobenzoic acid and 76.0Kg of N,N-dimethylacetamide were successively added into the reaction kettle. Stir and cool down to -10°C; slowly add 27.3Kg of liquid bromine, control the temperature at -10°C, and complete the addition in 2 hours. The reaction was incubated at -10°C for 2 hours. After the reaction was completed, 340.0Kg of water was slowly sucked in to quench the reaction, and after the dripping was completed, stirring was continued at 0°C for 1 hour. Centrifuge, and wash the filter cake once with 20.0Kg water. The wet product was dried at 60°C for 12 hours to obtain 25.6Kg of 5-amino-2-bromobenzoic acid with a yield of 81.3%.

[0070] The obtained 5-amino-2-bromobenzoic acid was detected by NMR and mass spectrometry, and the results showed that the target product 5-amino-2-bromobenzoic acid was obtained.

[0071] 37.5Kg of 98% sulfuric acid, 163.0Kg of water, 163.0Kg of tetrahydrofuran and 25.0Kg of prepared 5-amino-2-bromobenzoic acid were su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com