Preparation method of BC (bacterial cellulose) with high deformation resistance

A technology of bacterial cellulose, deformability, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., to achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

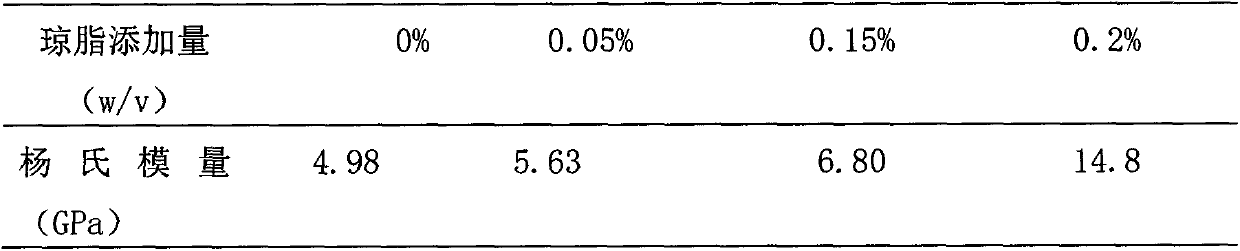

Embodiment 1

[0028] (1) Medium preparation (g / L): glucose 7.5, yeast powder 10, peptone 10, Na 2 HPO4 10, adjust the pH to 6.0 with glacial acetic acid, weigh 0.05% (w / v) agar into the liquid medium, and sterilize at 121° C. for 20 minutes.

[0029] (2) Strain activation: pick the Gluconacetobacter xylinum obtained from the three-section line on the plate and put it in a 500mL Erlenmeyer flask containing 150mL liquid medium, shake it at 30°C and 180r / min for 24h, and then inoculum with 6% Transfer to another two bottles of fresh culture medium, and cultivate to the logarithmic phase at 30°C and 180r / min shaking.

[0030] (3) Inoculation: Mix the two bottles of seed liquid in (2) evenly, inoculate into liquid medium, semi-solid medium and solid medium with 6% inoculum amount, and place it in a constant temperature incubator at 30°C for static cultivation 5 days.

[0031] (4) Bacterial cellulose extraction and treatment: use the membrane after it is taken out, and rinse with water several ...

Embodiment 2

[0034] (1) Medium preparation (g / L): glucose 7.5, yeast powder 10, peptone 10, Na 2 HPO4 10, adjust the pH to 6.0 with glacial acetic acid, weigh 0.15% (w / v) agar into the liquid medium, and sterilize at 121° C. for 20 minutes.

[0035] (2) Strain activation: pick the Gluconacetobacter xylinum obtained from the three-section line on the plate and put it in a 500mL Erlenmeyer flask containing 150mL liquid medium, shake it at 30°C and 180r / min for 24h, and then inoculum with 6% Transfer to another two bottles of fresh culture medium, and cultivate to the logarithmic phase at 30°C and 180r / min shaking.

[0036] (3) Inoculation: Mix the two bottles of seed liquid in (2) evenly, inoculate into liquid medium, semi-solid medium and solid medium with 6% inoculum amount, and place it in a constant temperature incubator at 30°C for static cultivation 5 days.

[0037] (4) Bacterial cellulose extraction and treatment: use the membrane after it is taken out, and rinse with water several ...

Embodiment 3

[0040] (1) Medium preparation (g / L): glucose 7.5, yeast powder 10, peptone 10, Na 2 HPO4 10, adjust the pH to 6.0 with glacial acetic acid, weigh 0.2% (w / v) agar into the liquid medium, and sterilize at 121° C. for 20 minutes.

[0041](2) Strain activation: pick the Gluconacetobacter xylinum obtained from the three-section line on the plate and put it in a 500mL Erlenmeyer flask containing 150mL liquid medium, shake it at 30°C and 180r / min for 24h, and then inoculum with 6% Transfer to another two bottles of fresh culture medium, and cultivate to the logarithmic phase at 30°C and 180r / min shaking.

[0042] (3) Inoculation: Mix the two bottles of seed liquid in (2) evenly, inoculate into liquid medium, semi-solid medium and solid medium with 6% inoculum amount, and place it in a constant temperature incubator at 30°C for static cultivation 5 days.

[0043] (4) Bacterial cellulose extraction and treatment: use the membrane after it is taken out, and rinse with water several ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com