Preparation method of layered porous active carbon electrode material for supercapacitor

A technology of porous activated carbon and supercapacitors, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

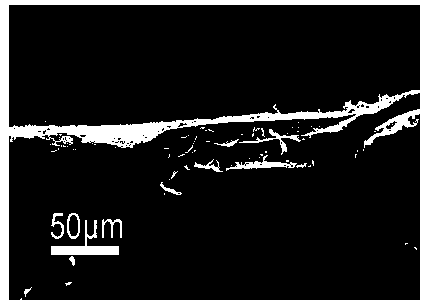

[0031] 1) Carbonization treatment of casings: Soak the casings in warm water at 60°C for 10 hours, wash and dry them, then weigh 10g casings, and weigh 10g casings by figure 1 It can be seen that the casing has an obvious layered structure.

[0032] The sausage casings were laid flat and stacked in a corundum boat, moved into a tube furnace under a nitrogen atmosphere, raised to 500°C at a heating rate of 1°C / min, and carbonized at a constant temperature for 5 hours to obtain a layered casing charcoal material.

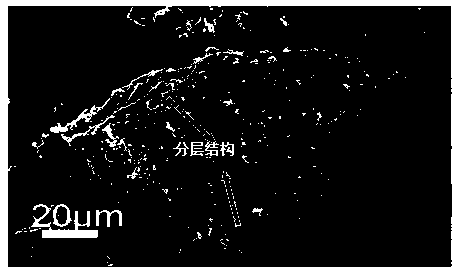

[0033] The SEM image of the above layered casing carbon material is shown in figure 2 shown by figure 2 It can be seen that the pre-carbonized casing material is irregular block with obvious layered structure, and the surface of the block sample is relatively smooth without obvious holes and channels.

[0034] 2) Weigh 12g of potassium hydroxide and dissolve it in an appropriate amount of deionized water to form lye.

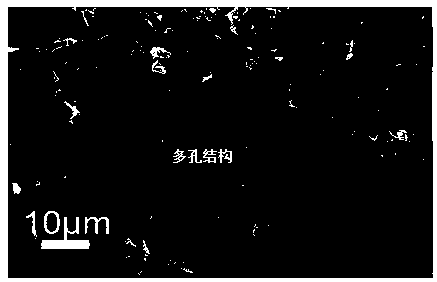

[0035] Weigh 3g of sausage-coated charcoal m...

Embodiment 2

[0043] 1) Carbonization treatment of casings: Soak the casings in warm water at 90°C for 5 hours, wash and dry them, weigh 10g of casings, lay them flat and stack them in a corundum boat, move them into a tube furnace under a nitrogen atmosphere, and heat up at a rate of 5°C / min The temperature was raised to 800°C, and carbonized at a constant temperature for 2 hours to obtain a layered casing carbon material.

[0044] 2) Weigh 15g of potassium hydroxide and dissolve it in an appropriate amount of deionized water to form lye.

[0045] Weigh 3g of sausage-coated charcoal material and add it to the lye, stir evenly with a glass rod, ultrasonicate for 30 minutes, seal with plastic wrap, soak for 5 hours at room temperature, and then dry in an oven to obtain a mixture.

[0046]3) Move the mixture into a nickel crucible, move it into a tube furnace under a nitrogen atmosphere, raise the temperature to 900°C at a heating rate of 10°C / min, activate at a constant temperature for 2 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com