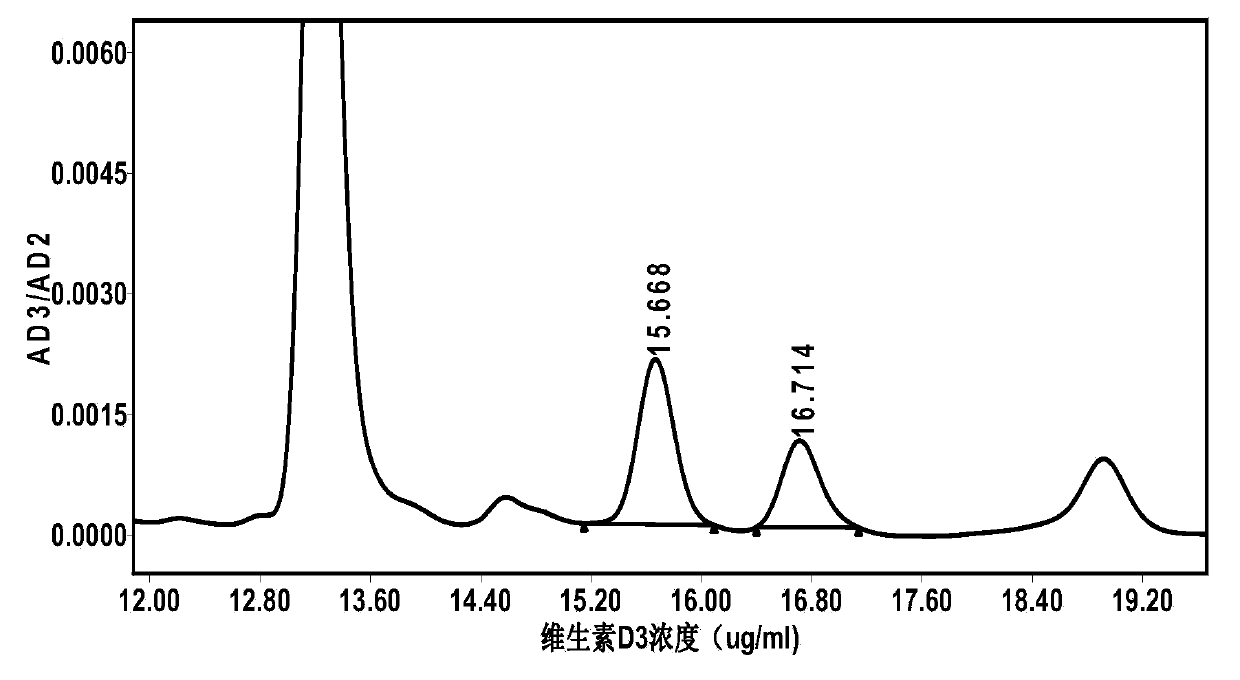

Method for measuring vitamin D3 in soybean protein powder

A technology of soybean protein powder and a determination method, which is applied in the field of determination of vitamin D3 in soybean protein powder, can solve the problems of difficulty in accurately controlling the outflow time of vitamin D3, easily destroyed vitamin content, high cost and high cost, and achieves the goal of being beneficial to popularization, popularization and use, and wide application. Market application prospects, accurate and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with specific embodiments.

[0045] 1. Reagents:

[0046] Aldehyde-free ethanol, ascorbic acid (or 2,6-di-tert-butyl-p-cresol), potassium hydroxide, n-hexane (chromatographically pure), anhydrous sodium sulfate, methanol (chromatographically pure), petroleum with a boiling point of 30-60°C ether;

[0047] The above reagents are all produced by Sinopharm Chemical Reagent Co., Ltd.; unless otherwise stated, the reagents used in this method are of analytical grade, and the water is the first-grade water specified in GB / T6682.

[0048] Amylase: activity unit ≥ 100U / mg.

[0049] 2. Reagent preparation:

[0050] 2.1 Potassium hydroxide solution: 50g potassium hydroxide, add 50ml water to dissolve, store in polyethylene bottle after cooling, prepare before use.

[0051] 2.2 Methanol solution: Accurately measure 5ml of water and add it to 95ml of methanol, mix well, ultrasonically degas, and set aside. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com