Method for producing itaconic acid in escherichia coli

A technology of Escherichia coli and itaconic acid, which is applied in the field of genetic engineering, can solve problems such as the inability to meet high-yield industrial production, and achieve the effect of easy mutual recognition and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

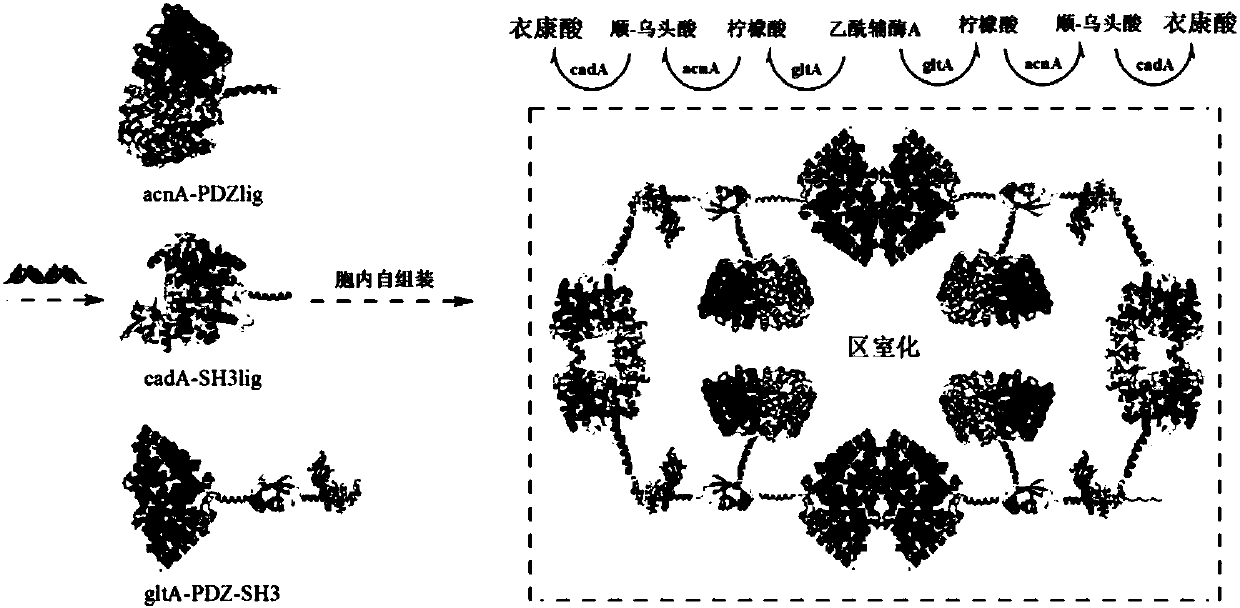

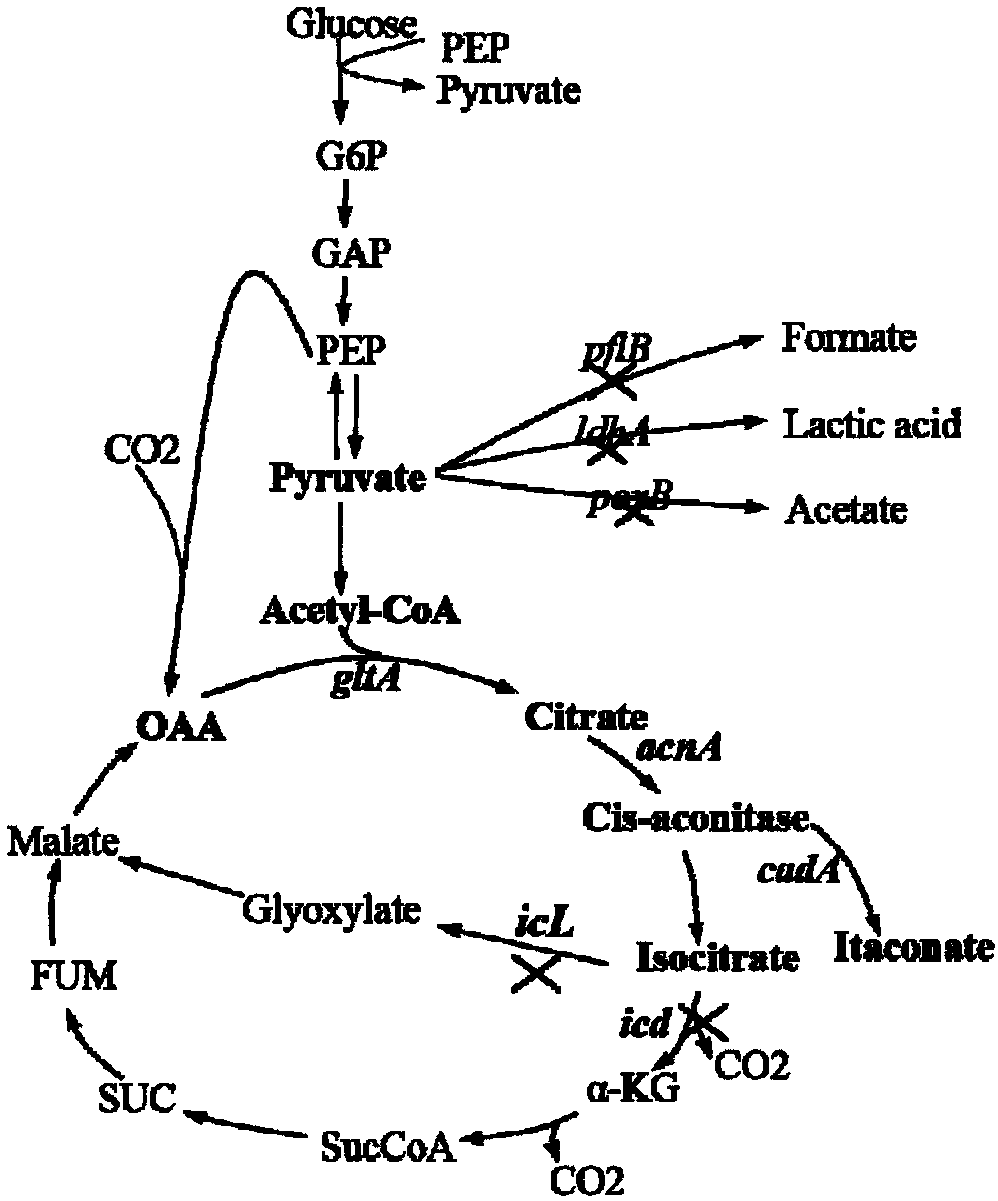

[0030] Construction and expression of embodiment 1 three-enzyme self-assembly plasmid

[0031] gltA (predicted as dimer enzyme) gene from Corynebacterium glutamicum (GenBank ID: 1018824), acnA (predicted as monomeric enzyme) from Corynebacterium glutamicum (GenBank ID: 1019512), cadA (predicted as Dimerase) was derived from Aspergillus terreus (GenBank ID: BAG49047.1). The genes gltA, acnA, and cadA are obtained through the whole gene synthesis of the biological company, and have undergone codon optimization. In addition, the genes PDZ and SH3 have been constructed in our laboratory and stored at -20°C.

[0032] Plasmid construction adopts a one-step cloning method. In this experiment, all plasmid backbones are inserted into the strong promoter BBa_J23100 for transformation, and the target gene is gene fused with the vector. The gltA and cadA genes were constructed in the plasmid pQE-30 to obtain the plasmid pQE30-cadA-gltA, and the ligand SH3lig of the SHM protein pair and ...

Embodiment 2

[0034] Embodiment 2 gltA, acnA and cadA enzymatic property characterization

[0035] Plasmids expressing gltA, acnA and cadA proteins alone were constructed and used as controls after separation and purification. The catalytic activities of the three fusion enzymes and their original enzymes were measured respectively, and their enzymatic properties were studied. The enzyme activity detection method is as follows:

[0036] 1) The enzyme activity of aconitic acid decarboxylase cadA was detected by the concentration of itaconic acid, and the cis-aconitic acid was reacted with the enzyme, and the amount of itaconic acid produced was detected by HPLC. The detection conditions are: Inertsil ODS-3column, 0.1M ammonium dihydrogen phosphate (pH 2.6) as the mobile phase, and the column temperature is 40°C. One unit of enzyme activity is defined as the amount of enzyme that catalyzes the production of 1 micromole of itaconic acid per minute at 37°C.

[0037] 2) The detection method o...

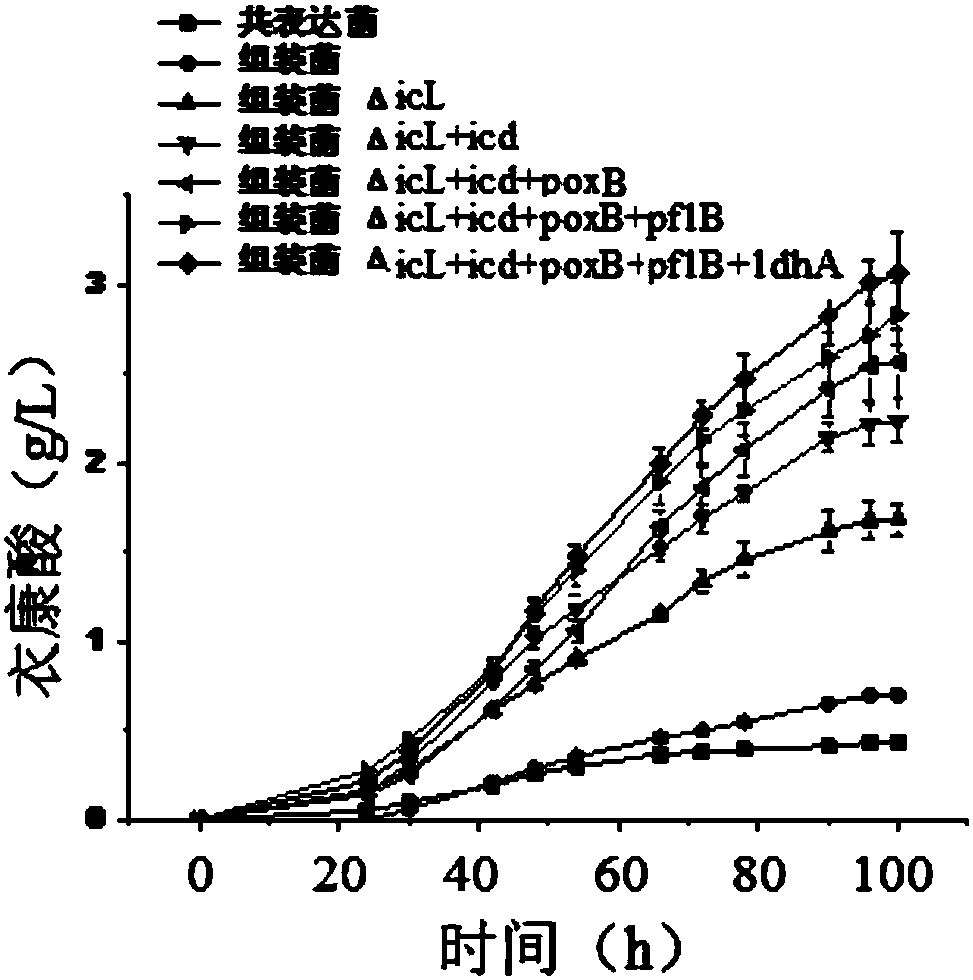

Embodiment 3

[0040] Example 3 Multi-enzyme in vitro assembly experiment

[0041] Multi-enzyme assembly, verification and characterization are carried out outside the cell, that is, non-denaturing electrophoresis, molecular exclusion chromatography, laser particle size analysis, dynamic light scattering and other technologies and activity detection are used to investigate the concentration, ratio and assembly time of each enzyme assembly on the assembly process. and cascade catalytic activity, and by means of atomic force microscopy (AFM) and scanning electron microscopy (SEM) to measure the morphology and surface morphology of the assembled multienzyme, and characterize the structure and compartmentalized geometric characteristics of the multienzyme. The intracellular assembly activity was verified by the amount of itaconic acid (HPLC detection), the product synthesized by final fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com