Patterned transparent back plate material

A patterned and transparent technology, applied in polyester coatings, rosin coatings, polyurea/polyurethane coatings, etc., can solve the problems of double-sided cells that do not achieve high light utilization, and achieve a simple and easy coating and curing process , the gain effect is obvious, and the attenuation effect is low after aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

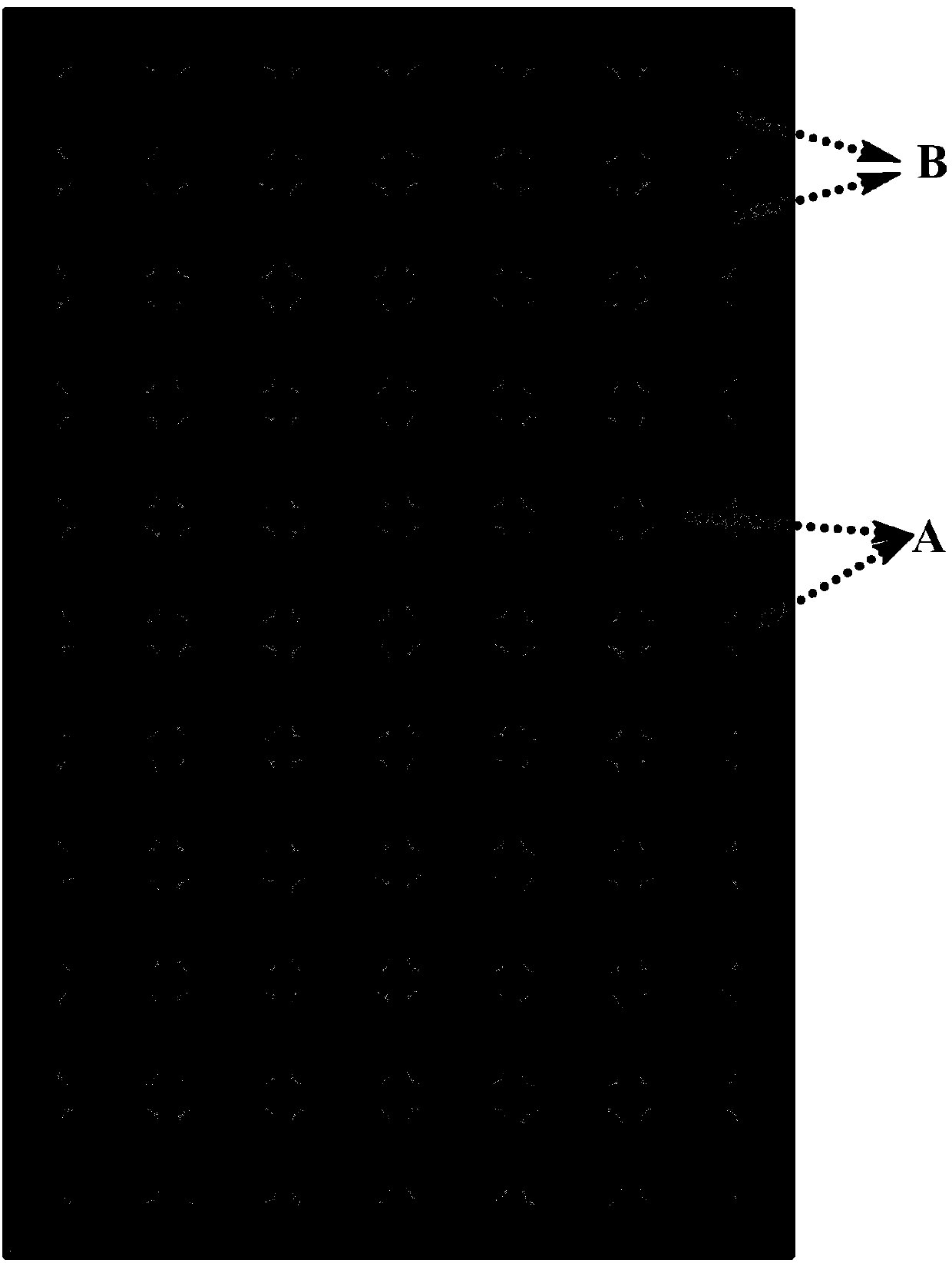

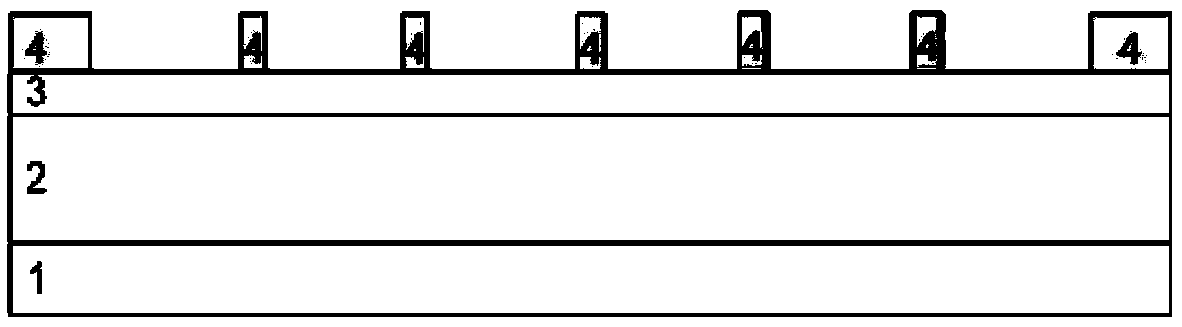

Image

Examples

Embodiment 1

[0067] The formula of matrix layer is as follows (mass fraction):

[0068] Polyethylene terephthalate (DuPont, USA) 90%;

[0069] Modified resin maleic anhydride graft compatibilizer C701 (Chuanju Chemical Technology Co., Ltd.) 5%;

[0070] Hydrolysis Stabilizer P200 (Rheinland Chemical) 0.01%;

[0071] Antioxidant tetrakis(3,5-di-tert-butyl-4-hydroxy)pentaerythritol phenylpropionate (Germany BASF) 0.01%;

[0072] Heat stabilizer hydrotalcite powder (Cunda Chemical Products Co., Ltd.) 4.95%;

[0073] The formula of weather-resistant layer is as follows (mass fraction):

[0074] Fluorine resin GK570 (Japan Daikin paint) 90%;

[0075] Hydroxy acrylic resin LR7765 (Mitsubishi, Japan) 5%;

[0076] Isophorone diisocyanate prepolymer (Japan Polyurethane Company) 3%;

[0077] UV absorber 3-[3-(2-H-benzotriazol-2-yl)-4-hydroxy-5-tert-butylphenyl]-propionic acid-polyethylene glycol ester (Taiwan Double Bond Chemical Company) 1.2%;

[0078] Light stabilizer poly{[6-[(1,1,3,3-tet...

Embodiment 2

[0095] The formula of matrix layer is as follows (mass fraction):

[0096] Polyethylene terephthalate (U.S. DuPont) 50%;

[0097] Modified resin M210 (Japan Zhongyuan) 30%;

[0098] Hydrolysis stabilizer I powder (Rheinland Chemical) 10%;

[0099] Antioxidant triethylene glycol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate (Yongguang Chemical, Taiwan, China) 5%;

[0100] Heat stabilizer N-phenylmaleimide-styrene-methyl methacrylate (Huawen Chemical Co., Ltd.) 5%;

[0101] The formula of weather-resistant layer is as follows (mass fraction):

[0102] Fluororesin T-1 (Sanaifu Chemical) 50%;

[0103] Terpene resin 803L (Yoshida Chemical Co., Ltd.) 30%;

[0104] White carbon black (Jinhe Nano Chemical Co., Ltd.) 3%;

[0105] Methylated polymethylol melamine resin (Changchun Chemical, Taiwan, China) 15%;

[0106] UV Absorber 2-[4-[2-Hydroxy-3-dodecyloxypropyl]oxy]-2-hydroxyphenyl]-4,6-bis(2,4-dimethylphenyl) -1,3,5-triazine (BASF, Germany) 0.8%;

[0107] Ligh...

Embodiment 3

[0122] The formula of matrix layer is as follows (mass fraction):

[0123] Polyethylene terephthalate (DuPont, USA) 62%;

[0124] Modified resin MR501 (Japan Zhongyuan) 20%;

[0125] Hydrolysis stabilizer UN-03 (Shanghai Union Chemical) 5%;

[0126] Antioxidant triethylene glycol ether-bis(3-tert-butyl-4-hydroxy-5-methylphenyl) propionate (BASF, Germany) 3%;

[0127] Heat stabilizer N-phenylmaleimide-styrene-methyl methacrylate (Huawen Chemical Co., Ltd.) 10%;

[0128] The formula of weather-resistant layer is as follows (mass fraction):

[0129] Fluororesin 4102 (Changxing Chemical) 40%;

[0130] Hydroxy polyester resin ST5790 (Japan Toyobo) 20%;

[0131] Scratch-resistant powder (Renqian Chemical Technology Co., Ltd.) 10%;

[0132] Hexamethylene diisocyanate prepolymer (Bayer, Germany) 20%;

[0133] UV absorber 2-(4,6-bis(2,4-dimethylphenyl)-1,3,5-triazin-2-yl)-5-octyloxyphenol (BASF, Germany) 4% ;

[0134] Light stabilizer bis(1,2,2,6,6-pentamethyl-4-piperidinyl)-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com