Preparation method for synthesizing methanol catalyst

A technology for synthesizing methanol and catalysts, which is applied in catalyst activation/preparation, organic compound preparation, chemical instruments and methods, etc., and can solve the problem of increasing the contact probability of active component copper and co-catalyst zinc, and the low activity and selectivity of copper-based catalysts. , the active components are not uniformly dispersed, etc., to achieve the effects of improved methanol selectivity and thermal stability, high active site density and small crystallites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

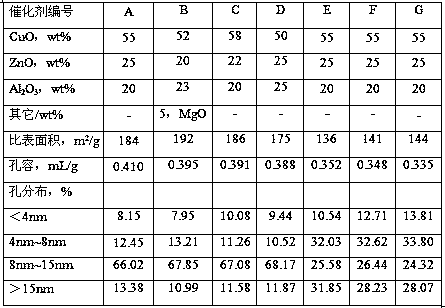

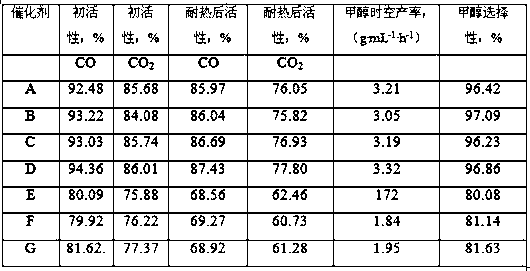

Embodiment 1

[0037] Weigh Cu(NO 3 ) 2 ·3H 2 O168g is dissolved in 600mL deionized water and is made into working solution A, Zn(NO 3 ) 2 ·6H 2 O78g was dissolved in 600mL deionized water to make working solution B. Add 450mL water in reaction tank, will contain Al 2 o 3 500ml of 20g / L sodium metaaluminate solution and solution A are added to the reaction tank in parallel flow, the gelling temperature is kept at 60°C, the pH value is controlled at 7.8 during the co-flow gelling reaction process, and the gelling time is controlled at 60 minutes. A slurry I containing copper and aluminum precipitates is generated. will contain Al 2 o 3 Add 500ml of 20g / L sodium metaaluminate solution to solution B under stirring, keep the gelling temperature at 60°C, control the pH value at the end of the process at 7.6, and control the gelling time at 60 minutes to form zinc and aluminum precipitate slurry II . Mix the above two kinds of sediment-containing slurries, and start aging while stirring...

Embodiment 2

[0039] According to the method of embodiment 1, press the component content ratio of catalyst B in table 1, add copper nitrate, magnesium chloride solution in dissolving tank 1, prepare working solution A, add zinc nitrate to prepare working solution B in dissolving tank 2 . Add 800mL of clean water into the reaction tank, and 2 o 3 850 ml of 20g / L sodium metaaluminate solution and solution A are added to the reaction tank in parallel flow, the gelling temperature is kept at 55°C, the pH value is controlled at 7.8 during the concurrent gelling reaction process, and the gelling time is controlled at 60 minutes. A slurry I containing copper, magnesium and aluminum precipitates is generated. will contain Al 2 o 3 Add 600ml of 30g / L sodium metaaluminate solution to solution B under stirring, keep the gelling temperature at 65°C, control the pH value at the end of the process at 7.4, and control the gelling time at 50 minutes to generate a slurry containing zinc and aluminum pr...

Embodiment 3

[0041] According to the method of Example 1, according to the component content ratio of catalyst C in Table 1, copper nitrate was added to dissolving tank 1 to prepare working solution A, and zinc nitrate was added to dissolving tank 2 to prepare working solution B. Add 1000mL of clean water into the reaction tank, and 2 o 3 600 ml of 20g / L sodium metaaluminate solution and solution A are added into the reaction tank in parallel flow, the gelling temperature is kept at 70°C, the pH value is controlled at 7.6 during the concurrent gelling reaction process, and the gelling time is controlled at 70 minutes. A slurry I containing copper and aluminum precipitates is generated. will contain Al 2 o 3 320 ml of 25g / L sodium metaaluminate solution, add solution B under stirring, keep the gelling temperature at 50°C, control the pH value at the end of the process at 7.8, control the gelling time at 60 minutes, and form zinc and aluminum precipitates Serum II. Mix the above two slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com