Aqueous solution sprayable trimethylene dioxythiophene polymer blue-transparent electrochromic material, preparation method, component and application

A propylene dioxythiophene, electrochromic material technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of large environmental pollution, high production cost, high price, etc., and achieve high optical contrast and oxidation state transparency. , the effect of short response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

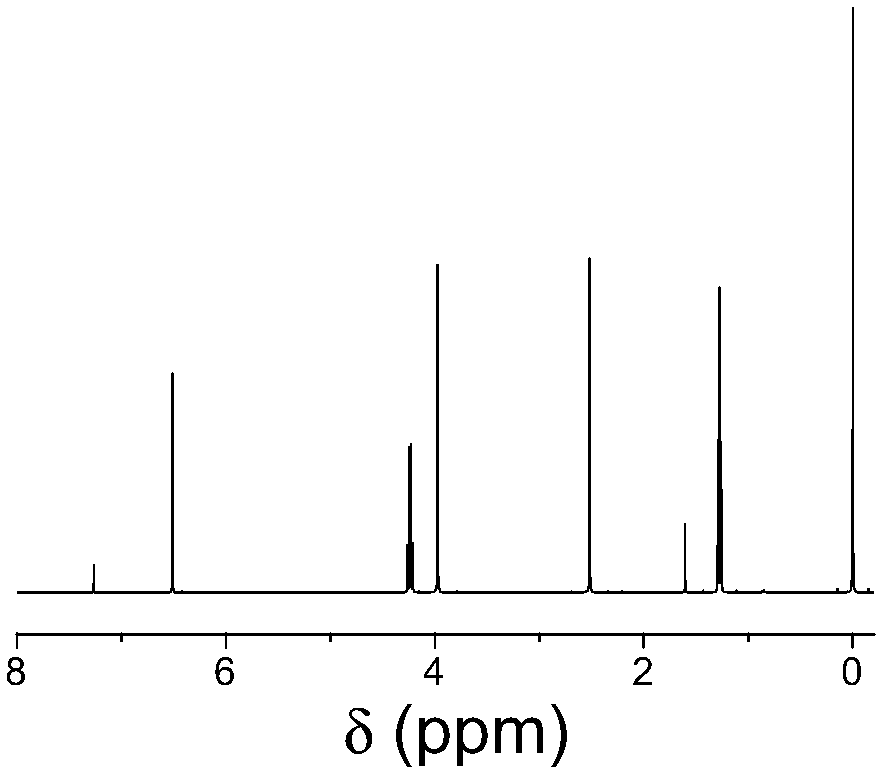

[0036] Embodiment 1 Propylenedioxythiophene polymer blue-transparent electrochromic film

[0037] A kind of preparation method of propylene dioxythiophene polymer blue-transparent electrochromic film is:

[0038] Step 1. Add 35mmol 3,4-dimethoxythiophene, 70mmol dibromoneopentyl glycol, 3.5mmol p-toluenesulfonic acid and 300mL toluene to the flask connected to the Soxhlet extractor containing molecular sieve, and heat to reflux Overnight, then cooled to room temperature, washed with water, the organic phase was dried with anhydrous sodium sulfate, and then the solvent was removed by rotary evaporation. The resulting crude product was subjected to column chromatography to obtain compound 1, with a yield of 60%;

[0039] Step 2. Add 16mmol of compound 1, 32mmol of diethyl malonate, and 64mmol of sodium ethoxide into the flask connected with a reflux condenser at the top, heat to reflux for 8h, then cool to room temperature, add an appropriate amount of water, extract several tim...

Embodiment 2

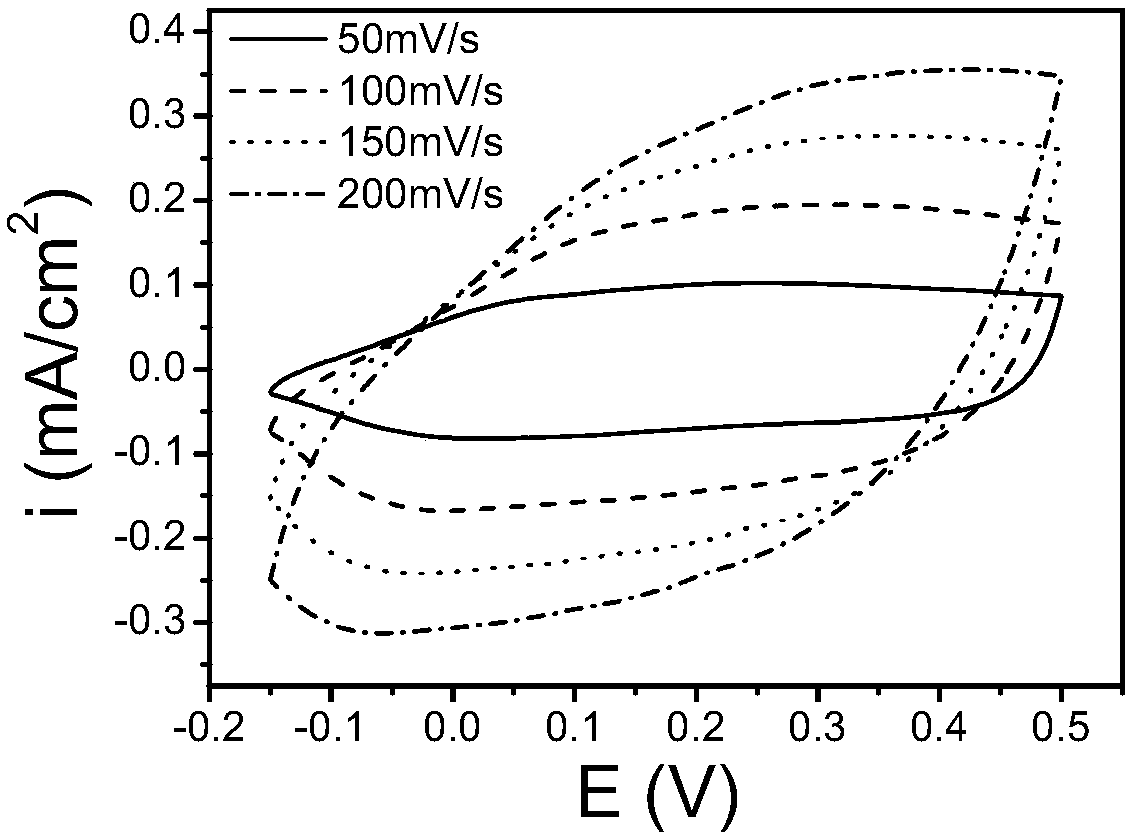

[0045]Example 2 Propylenedioxythiophene polymer blue-transparent electrochromic film (PProDOTCB-Acid) cyclic voltammetry experiment

[0046] The thin film that embodiment 1 is made carries out cyclic voltammetry test, and cyclic voltammetric test condition: adopt three-electrode electrolytic cell, Pt wire is counter electrode, and Ag wire is reference electrode, the polymer thin film (2cm × 0.7cm) ITO conductive glass is the working electrode, the scanning voltage range is -0.15V-0.5V, and the scanning rates are 50mV / s, 100mV / s, 150mV / s, 200mV / s; support electrolyte configuration: 0.1mol / L high Lithium chlorate (LiClO 4 ) was dissolved in 10 mL of propylene carbonate (PC). see test results image 3 , indicating that when the scanning rate is 50mV / s, the oxidation peak potential of the polymer is 0.25V, and the reduction peak potential is 0.05V, and the polymer can complete the redox process within the scanning voltage range of -0.15V-0.5V.

Embodiment 3

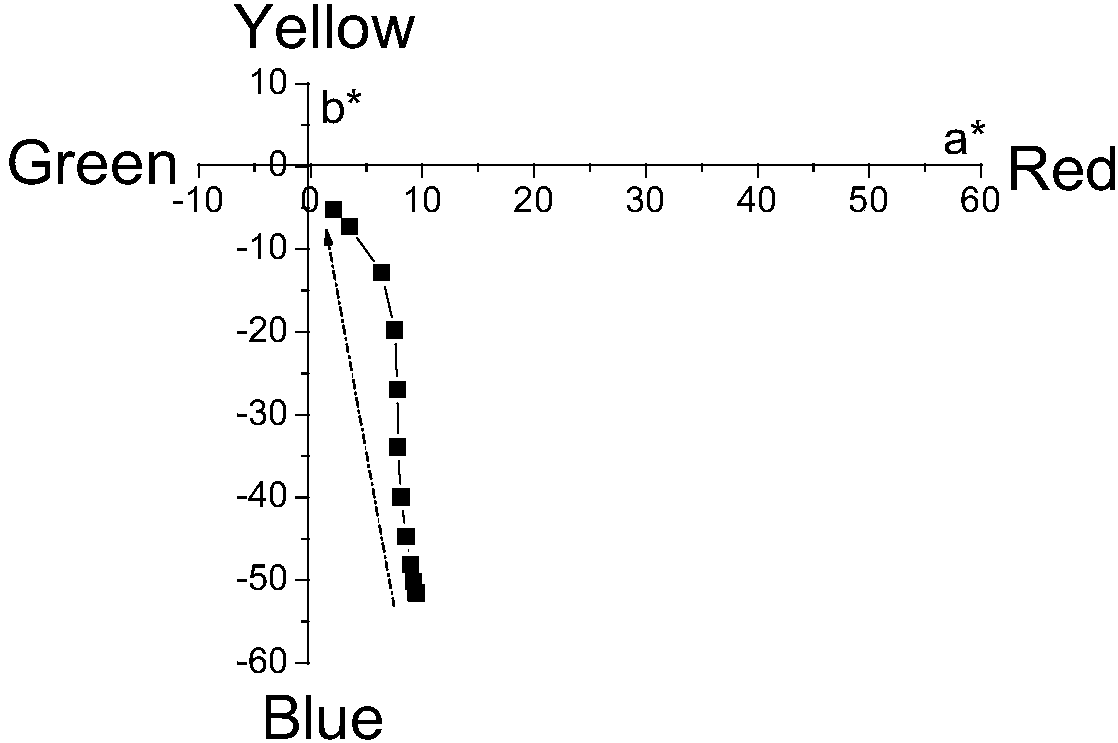

[0047] Example 3 Spectroelectrochemical performance test of propylenedioxythiophene polymer blue-transparent electrochromic film (PProDOTCB-Acid) under different applied voltages

[0048] Experimental conditions: supporting electrolyte configuration: 0.1mol / L lithium perchlorate (LiClO 4 ) was dissolved in 10 mL of propylene carbonate (PC). Adopt three-electrode electrolytic cell, Pt silk is counter electrode, and Ag silk is reference electrode, and the polymer film (2cm * 0.7cm) ITO conductive glass that embodiment 1 prepares is working electrode, test result sees Figure 4 . It shows that the neutral state polymer film (-0.15V) is blue, and the maximum absorption wavelength is 580nm, and the fully oxidized state (0.5V) of the polymer is a transparent state, and there is basically no absorption in the visible light region.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com