High-throughput microalgae growth testing device and method

A testing device and high-throughput technology, which is applied in the field of photosynthetic microorganism cultivation and detection, can solve problems such as poor parallelism, uneven cell dispersion, and limited number of groups, and achieve high reliability of parallelism, shortened research time, and save The effect of sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following examples further illustrate the content of the present invention, but should not be construed as limiting the present invention. Without departing from the spirit and essence of the present invention, any modifications or substitutions made to the methods, steps or conditions of the present invention fall within the scope of the present invention.

[0038] Unless otherwise specified, the technical means used in the embodiments are conventional means well known to those skilled in the art.

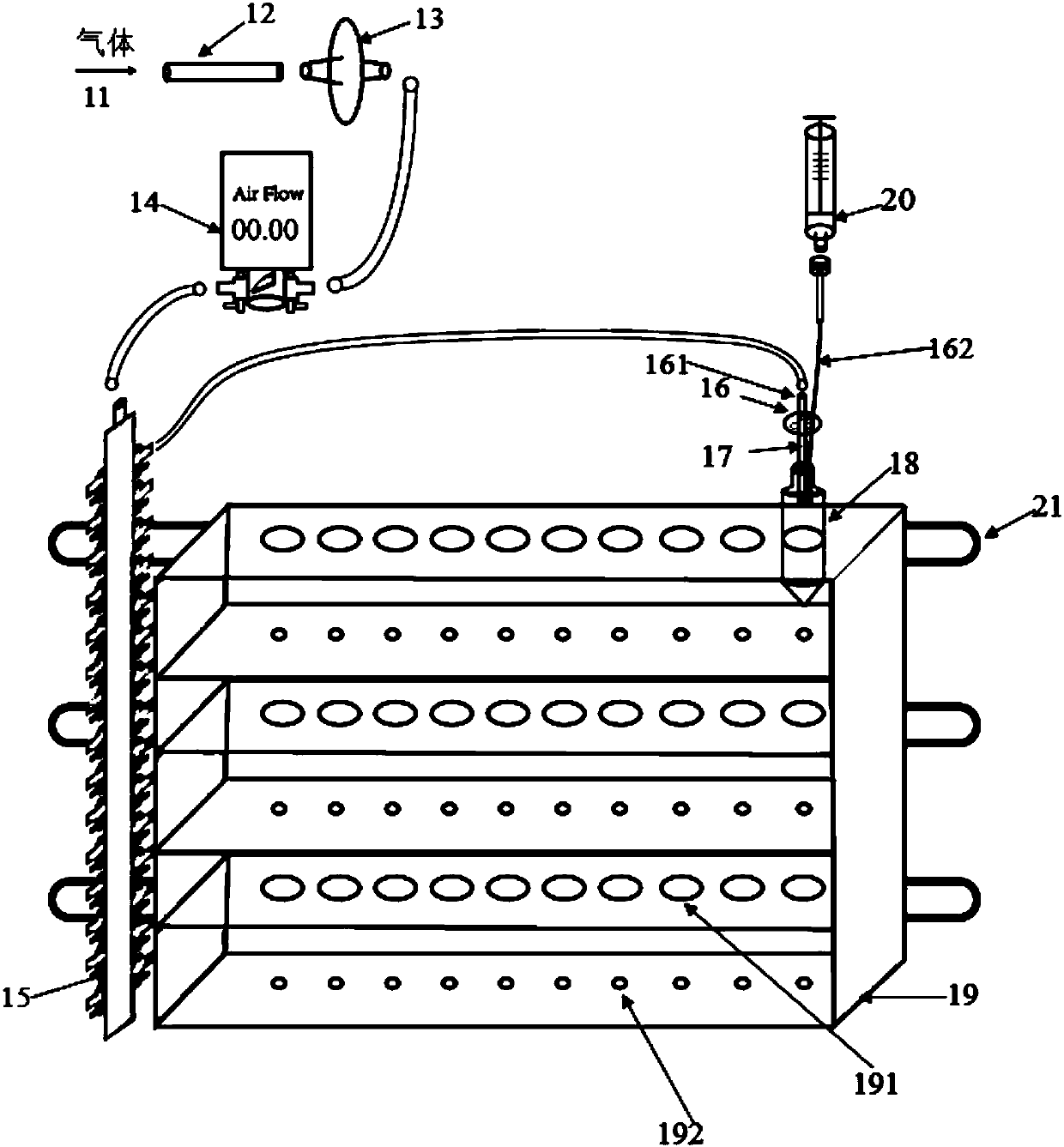

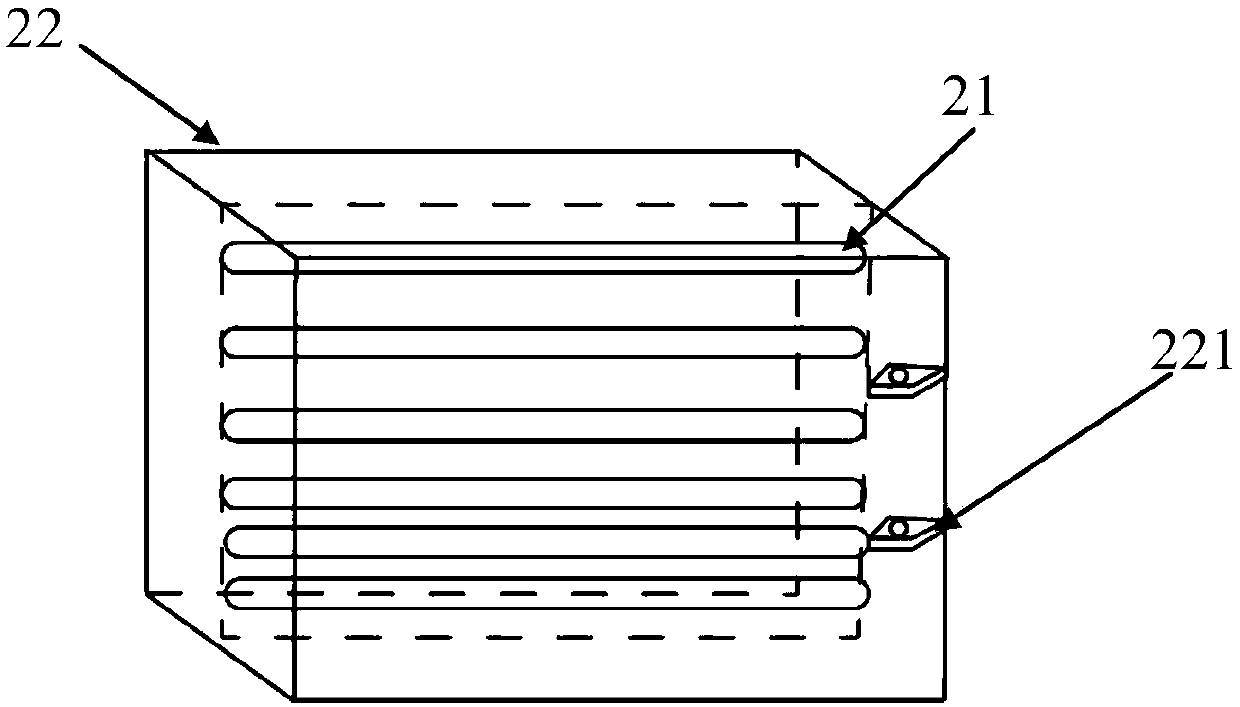

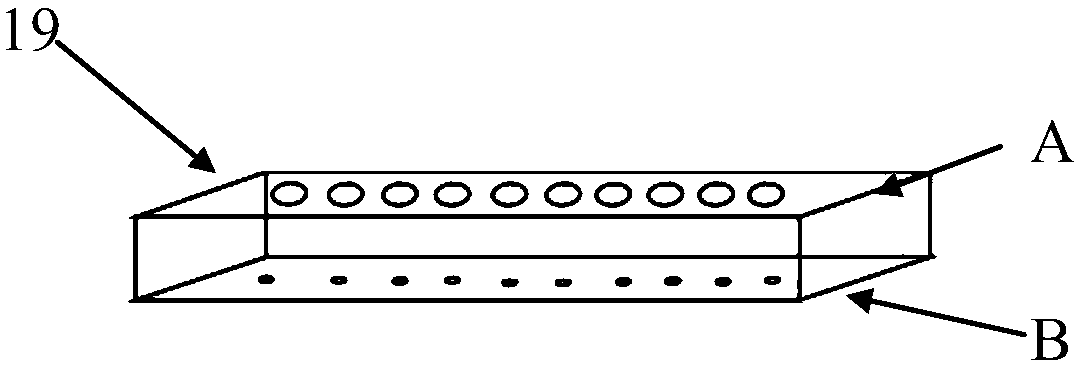

[0039] combine Figure 1-2 As shown, a high-throughput microalgae growth test device includes an illumination and air supply adjustment box 22, and a culture frame body 12, a light source 21, a milliliter-level culture bottle 18, a gas multi-valve shunt regulator 15, and a CO 2 Or an air source 11 and a gas filter 13 , the gas filter 13 is also connected to a digital gas flow meter 14 to monitor the gas flow entering the gas multi-valve shunt regulator 15 . The specif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com