A kind of preparation method of high temperature resistant methanation catalyst

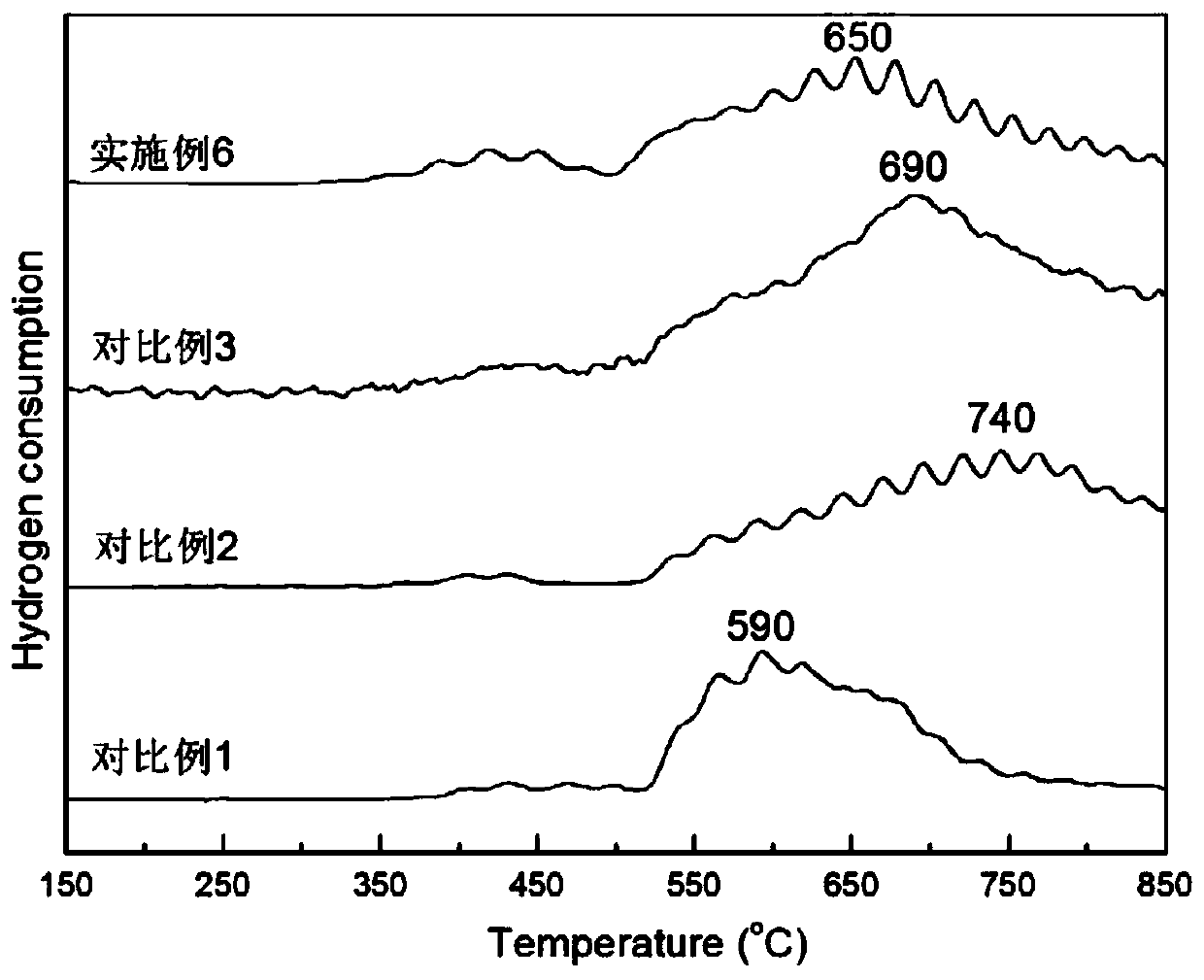

A methanation catalyst and high temperature resistant technology, applied in catalyst activation/preparation, carbon compound catalysts, catalysts, etc., can solve the problems of easy breakage, easy sintering of active components, easy carbon deposition and deactivation, etc. Good anti-sintering ability and the effect of improving catalyst strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

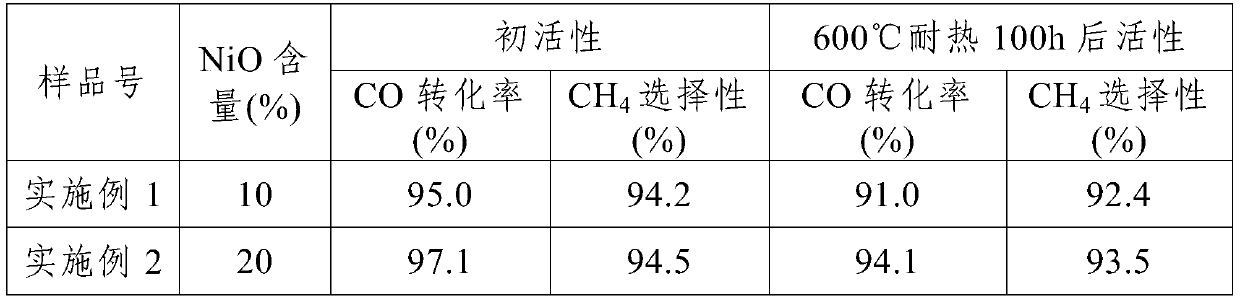

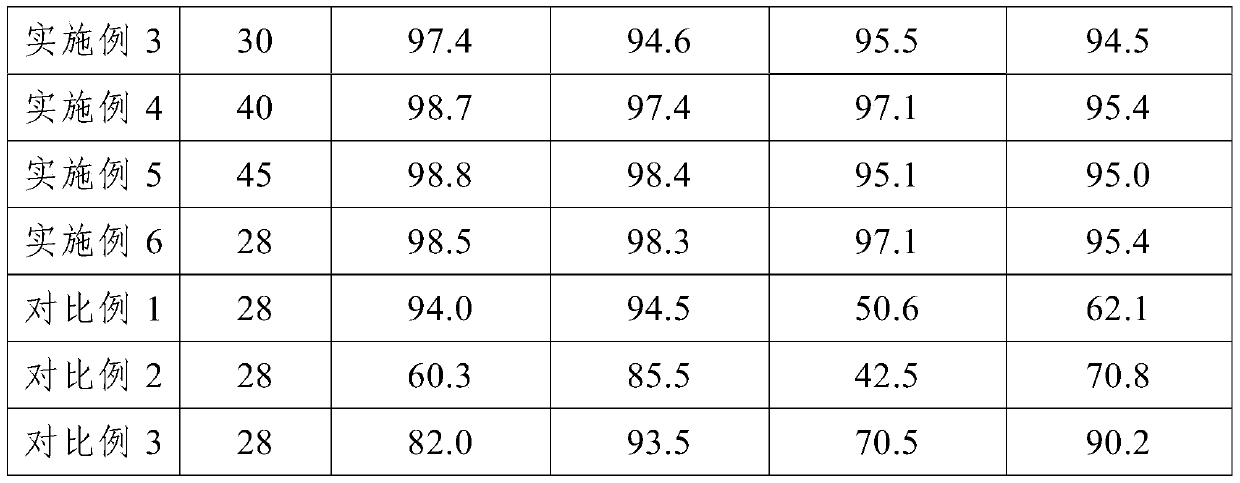

Embodiment 1

[0027]Dissolve 38.9g nickel nitrate hexahydrate and 2.5g aluminum nitrate nonahydrate in 1300mL water to prepare a mixed solution; in addition, dissolve 15.3g sodium carbonate in 1400mL water, add the mixed solution into the sodium carbonate solution at 25°C and stir for precipitation Reaction: After the precipitation reaction is finished, add 0.5g of tetramethoxysilane and stir evenly, then add 115.3g of pseudo-boehmite, stir and mix evenly, then filter and wash with water for several times and then dry at 80°C for 5h to remove water, and the dried material is calcined at 320°C for 10 hours, then mixed with graphite and pressed into tablets to obtain a finished high-temperature-resistant methanation catalyst.

[0028] In this embodiment, the finished high-temperature-resistant methanation catalyst is composed of the following components in mass percent: 10% nickel oxide, 89% aluminum oxide, 0.2% silicon dioxide, and the balance is graphite.

Embodiment 2

[0030] Dissolve 63.6g of nickel chloride hexahydrate and 7.1g of aluminum chloride in 750mL of water; in addition, dissolve 36.9g of sodium carbonate in 1000mL of water, add nickel chloride and aluminum chloride solution into the sodium carbonate solution at 25°C for precipitation After the precipitation is complete, add 1.7g of tetraethoxysilane and stir evenly, then add 99.7g of boehmite, stir and mix evenly, then filter and wash with water for several times and then dry at 80°C for 5h to remove water. After drying, the material is in Calcined at 380°C for 5 hours, then mixed with graphite and pressed into tablets to obtain a finished high temperature resistant methanation catalyst.

[0031] In this embodiment, the finished high-temperature-resistant methanation catalyst is composed of the following components in mass percent: 20% nickel oxide, 78.5% aluminum oxide, 0.5% silicon dioxide, and the balance is graphite.

Embodiment 3

[0033] Dissolve 100.0g nickel acetate and 120.5g aluminum nitrate nonahydrate in 500mL water; in addition, dissolve 122.0g potassium carbonate in 1000mL water, add nickel nickel acetate and aluminum nitrate solution to potassium carbonate solution at 50°C for precipitation; precipitation is complete Finally, add 11.7g of silica sol with 20% solid content and stir evenly, then add 62.0g of aluminum hydroxide, stir and mix evenly, then filter and wash with water for several times, then dry at 80°C for 5h to remove water, and dry the material at 450°C Calcined at lower temperature for 2 hours, then mixed with graphite and pressed into tablets to obtain a finished product of high temperature resistant methanation catalyst.

[0034] In this embodiment, the finished high-temperature-resistant methanation catalyst is composed of the following components in mass percent: 30% nickel oxide, 61% aluminum oxide, 5% silicon dioxide, and the balance is graphite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com