Lithium ion battery anode material and preparation method thereof

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as weak binding force of negative electrode material particles, residual metal impurities, complex preparation process, etc., to improve firmness, increase voltage Solid density, the effect of increasing the energy density of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

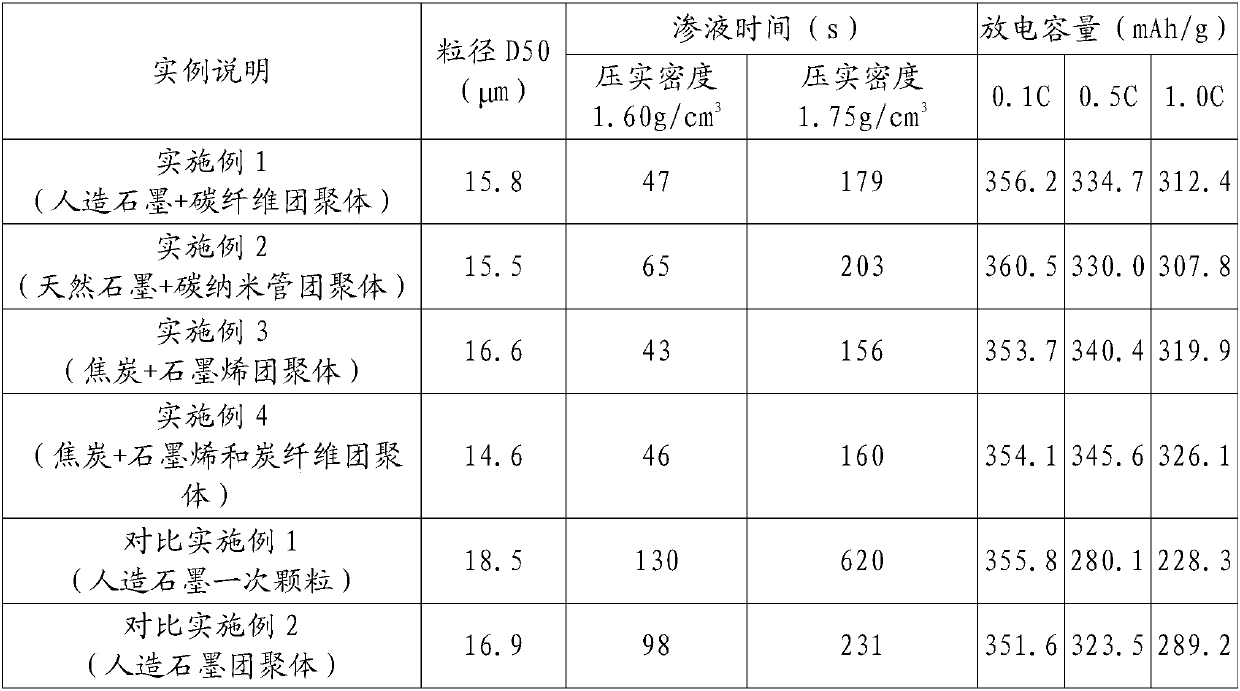

Embodiment 1

[0031] (1) Provide high-temperature coal pitch with an average particle size of 8μm spherical artificial graphite, a carbon fiber with a diameter of about 300nm and a length of about 3-6um, and an average particle size of 3μm;

[0032] (2) The above-mentioned carbon fiber and pitch are mixed uniformly in solid phase at a mass ratio of 30:70, heated to 280°C, stirred for 3 hours, cooled, and pulverized to an average particle size of 20 μm to obtain intermediate material one;

[0033] (3) The above-mentioned artificial graphite and the intermediate material are mixed uniformly in a solid phase with a mass ratio of 80:20 to obtain a mixture;

[0034] (4) Put the mixture in a pressure-resistant heating reaction vessel, stir, pass inert gas to replace the air in the reaction vessel, heat up to 450°C for 2h, then heat up to 650°C for 3h; heat up and keep warm Continuous stirring during the process; then cooling;

[0035] (5) Carbonization, under the protection of inert gas, heat treatment i...

Embodiment 2

[0039] (1) Provide medium temperature petroleum pitch with an average particle size of 8μm spherical natural graphite, a carbon nanotube with a diameter of about 60nm and a length of 1-10μm, and an average particle size of 10μm;

[0040] (2) Ball mill the above-mentioned carbon nanotubes and conductive carbon black in anhydrous ethanol at a mass ratio of 60:40 for 2h, and dry; this step can make the carbon nanotubes easier to disperse in the subsequent steps; it can be understood that anhydrous ethanol is also It can be replaced by other types of solvents such as acetone, aqueous solutions containing dispersants, and the like.

[0041] (3) Mix the mixture of carbon nanotubes and conductive carbon black with the above pitch at a mass ratio of 30:70 in solid phase, heat to 150°C, stir for 3 hours, cool, and pulverize to an average particle size of 50μm. Material one

[0042] (4) The above-mentioned natural graphite and the intermediate material are mixed uniformly in a solid phase wit...

Embodiment 3

[0048] (1) Provide spherical coke with an average particle size of 6μm, graphene with a thickness of about 8nm, and high-temperature coal pitch with an average particle size of 3μm;

[0049] (2) The above-mentioned graphene, pitch and silicon carbide are mixed uniformly in a solid phase at a mass ratio of 46:46:8, heated to 280°C, stirred for 3 hours, cooled, and pulverized to an average particle size of 5μm to obtain intermediate material one; Silicon carbide as a graphitizing agent can also be replaced by iron oxide, titanium oxide and other types or used together;

[0050] (3) Mix the coke and the intermediate material in a solid phase with a mass ratio of 90:10 to obtain a mixture;

[0051] (4) Put the mixture in a pressure-resistant heating reaction vessel, stir, pass inert gas to replace the air in the reaction vessel, heat up to 450°C for 2h, then heat up to 650°C for 3h; heat up and keep warm Continuous stirring during the process; then cooling;

[0052] (5) Carbonization, un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com