PCL/HA composite porous bone tissue engineering scaffold and preparation method thereof

A tissue engineering scaffold and porous bone technology, which can be applied in tissue regeneration, medical science, prosthesis, etc., can solve the problems of slow degradation rate and high brittleness, and achieve good degradation performance, no biotoxicity, and excellent biocompatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

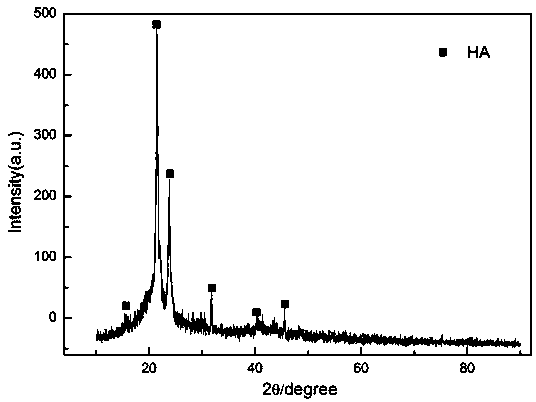

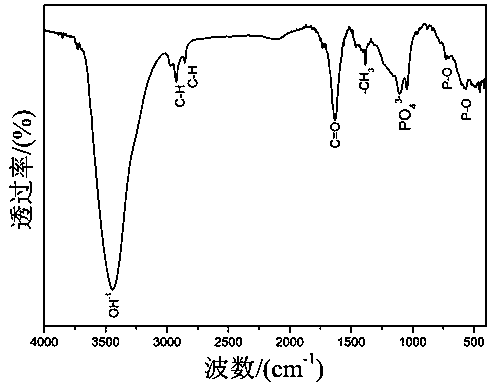

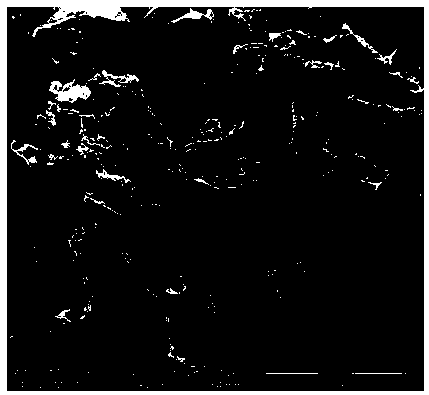

[0024] Example 1: The PCL / HA composite porous bone tissue engineering scaffold in this example is composed of polycaprolactone and hydroxyapatite. In terms of mass percentage, the content of hydroxyapatite is 0.5%, and the rest is polycaprolactone; Among them, the porosity of the scaffold is 89.4%, the diameter of the irregular through-holes is 10-300μm, and the compressive strength is 0.98Mpa;

[0025] (1) Dissolve polycaprolactone in an organic solvent (the organic solvent is dichloromethane), then add a pore-forming agent (the pore-forming agent is sodium bicarbonate) at room temperature and disperse evenly under stirring conditions to obtain Mixture A; wherein the solid-to-liquid ratio g:mL of polycaprolactone to the organic solvent is 1:10, and the solid-to-liquid ratio g:mL of the pore-forming agent (sodium bicarbonate) to the organic solvent is 1:1;

[0026] (2) Add hydroxyapatite to the mixture A obtained in step (1) at room temperature and disperse evenly under stirri...

Embodiment 2

[0037] Example 2: The PCL / HA composite porous bone tissue engineering scaffold in this example is composed of polycaprolactone and hydroxyapatite. In terms of mass percentage, the content of hydroxyapatite is 10%, and the rest is polycaprolactone; Among them, the porosity of the scaffold is 65.5%, the diameter of the irregular through-holes is 10-300μm, and the compressive strength is 2.48Mpa;

[0038] (1) Dissolve polycaprolactone in an organic solvent (the organic solvent is chloroform), then add a pore-forming agent (the pore-forming agent is sodium carbonate) at a temperature of 45°C and disperse evenly under stirring conditions to obtain Mixture A; wherein the solid-to-liquid ratio g:mL of polycaprolactone to the organic solvent is 1:6, and the solid-to-liquid ratio g:mL of the pore-forming agent (sodium carbonate) to the organic solvent is 1:1;

[0039] (2) At a temperature of 55°C, add hydroxyapatite to the mixture A obtained in step (1) and disperse evenly under stirri...

Embodiment 3

[0050] Example 3: The PCL / HA composite porous bone tissue engineering scaffold in this example is composed of polycaprolactone and hydroxyapatite whiskers. In terms of mass percentage, the content of hydroxyapatite is 50%, and the rest is polycaprolactone Ester; the porosity of the scaffold is 10%, the diameter of the irregular through-holes is 10-300μm, and the compressive strength is 10.20Mpa;

[0051] (1) Dissolve polycaprolactone in an organic solvent (the organic solvent is a mixture of chloroform and carbon tetrachloride), and then add a pore-forming agent at a temperature of 80°C (the pore-forming agent is potassium carbonate (K 2 CO 3 ) and potassium bicarbonate (KHCO 3 ) mixture) and uniformly disperse under stirring conditions to obtain mixture A; wherein the solid-liquid ratio g:mL of polycaprolactone and organic solvent is 1:5, and the solid-liquid ratio g:mL of pore-forming agent and organic solvent is 1 :1;

[0052] (2) At a temperature of 80°C, add hydroxyapa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com