a co 2 Method for preparing aromatic acid by direct carboxylation method

An aromatic acid and carboxylation technology, which is applied in the field of preparing aromatic acids by CO2 direct carboxylation, can solve the problems of harsh operating conditions, strong Lewis corrosion to equipment, and high catalyst cost, and achieves improved reaction selectivity, excellent solubility, The effect of shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] In the preparation method of the present invention: aromatic hydrocarbon is benzene, alkyl substituted benzene (alkyl substituted benzene is toluene, 1,2-xylene, 1,3-xylene, 1,4-xylene, 1,3,5- trimethylbenzene, ethylbenzene, propylbenzene or tert-butylbenzene), halogenated benzene, naphthalene or alkyl-substituted naphthalene;

[0040] Lewis acid is AlCl 3 , AlBr 3 , FeCl 3 , FeBr 3 , BF 3 , SbF 5 , NbCl 5 and La(CF 3 SO 3 ) 3 One of, preferably AlCl 3 , less preferably AlBr 3 , FeCl 3 or FeBr 3 ;

[0041] Organic bases include alkylamines (alkylamines are primary amines R-NH 2 , secondary amine R 1 R 2 -NH or tertiary amine R 1 R 2 R 3 -N, where R 1 , R 2 and R 3 Both are C 1 ~C 18 Alkyl, allyl and various secondary or tertiary alkyl groups), imidazole / N-alkyl substituted imidazole (in imidazole / N-alkyl substituted imidazole, the alkyl is C 1 ~C 18 Alkyl, allyl and various secondary or tertiary alkyl groups), pyridine / alkyl substituted pyridin...

Embodiment 1

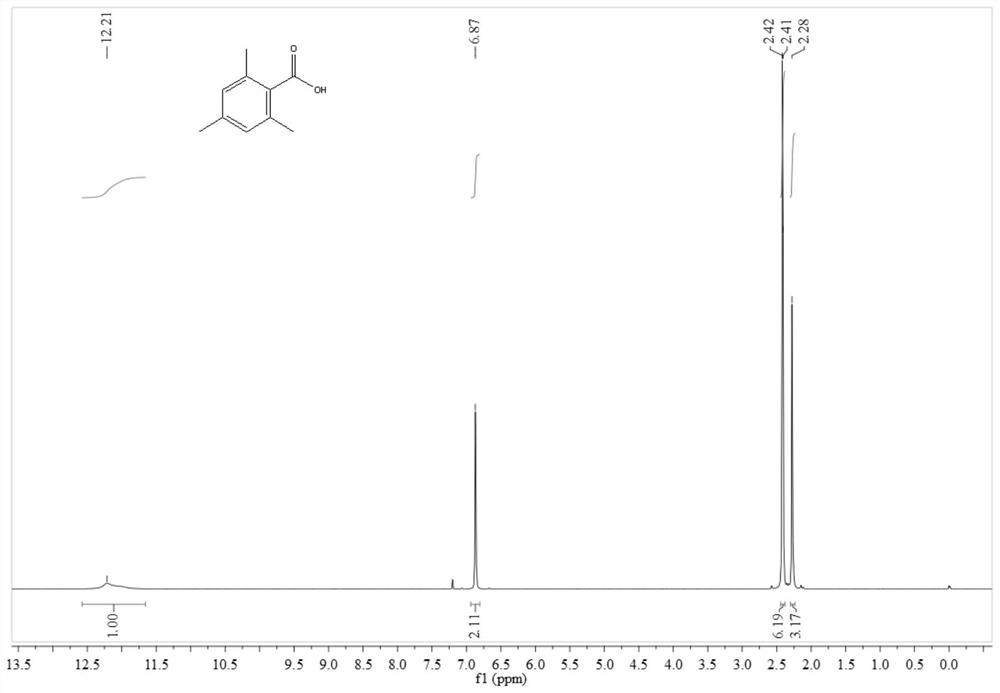

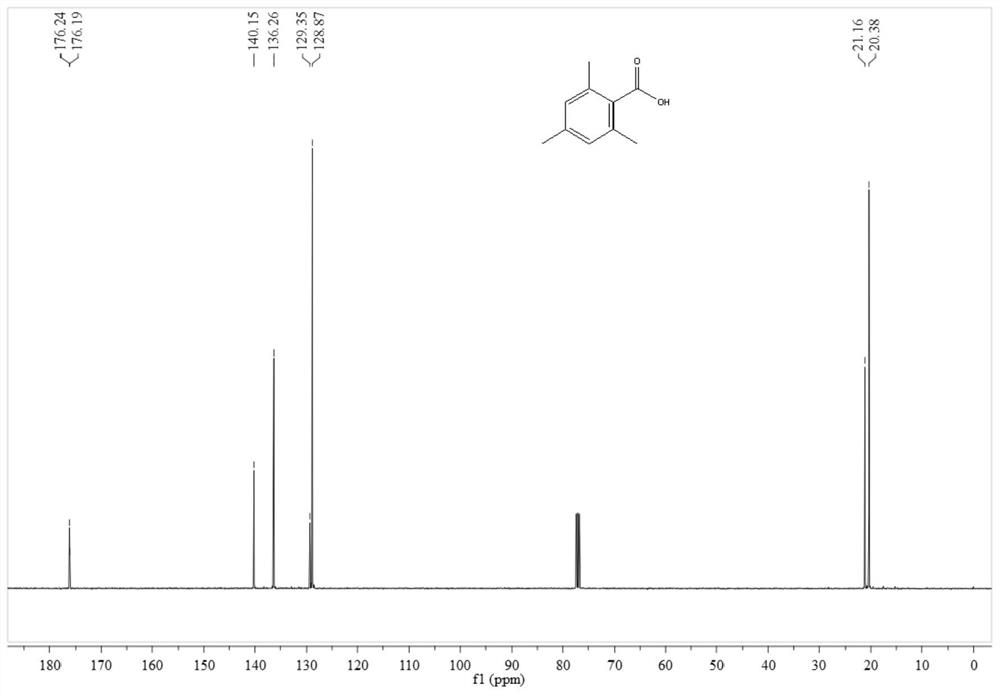

[0043] Under argon atmosphere, quickly add 40mL dry 1,3,5-trimethylbenzene, 2.5g anhydrous AlCl 3 , 1.76g of dry N-methyldicyclohexylamine, and the reaction kettle was sealed after the feeding was completed. Then CO 2 The cylinder is connected to the autoclave through the pipeline, and the valve is opened to control the CO 2 The pressure was 6MPa, and at the same time, the stirring was started at a stirring rate of 1000 rpm, and finally heating was started and kept at 40°C for 30h. After the reaction was completed, 150 mL of water was added to the reaction system, and the reaction was carried out for 30 min under stirring conditions, and then extracted three times with 50 mL of ether, and the extracts were combined and concentrated to dryness to obtain 2.72 g of off-white solid. Dissolve the above-mentioned off-white solid in 20mL of 10%wt sodium hydroxide solution, filter the insoluble matter to obtain the filtrate, then adjust the pH value of the filtrate to 1 with 1mol / L ...

Embodiment 2

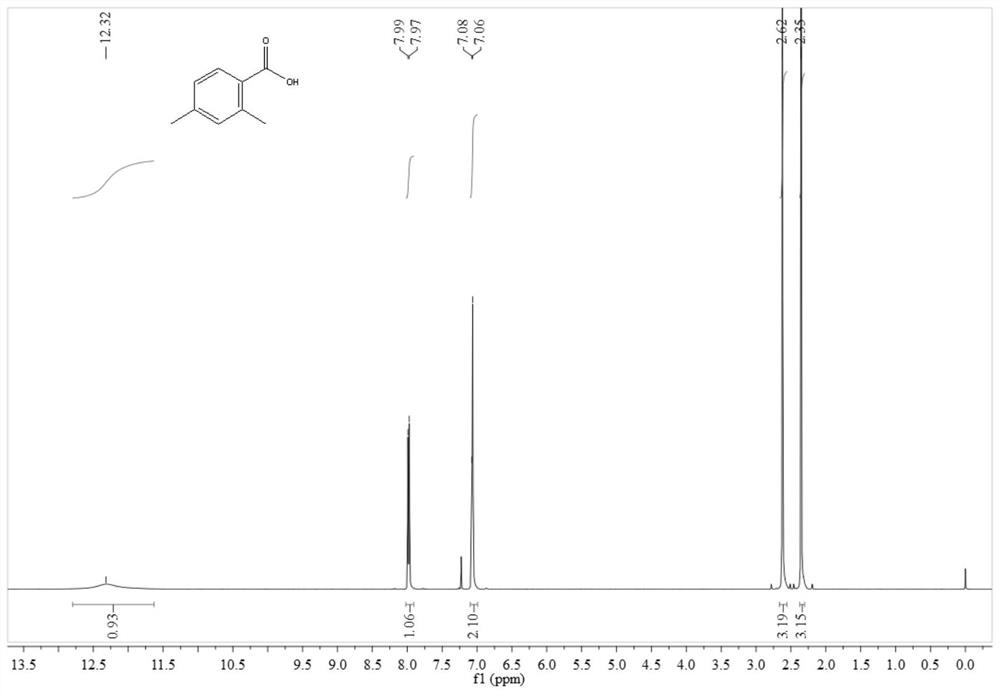

[0045] Under argon atmosphere, quickly add 40mL dry 1,3,5-trimethylbenzene, 2.5g anhydrous AlCl 3 , 0.54g of dry 1-allylimidazole, and the reaction kettle was sealed after the feeding was completed. Then CO 2 The cylinder is connected to the autoclave through the pipeline, and the valve is opened to control the CO 2 The pressure was 6MPa, and at the same time, the stirring was started at a stirring rate of 1000rpm, and finally heating was started and kept at 40°C for 24h. After the reaction was completed, 150 mL of water was added to the reaction system, and the mixture was reacted for 30 min under stirring, and then extracted three times with 50 mL of ether. The extracts were combined, concentrated and dried to obtain 2.85 g of off-white solid. Dissolve the above-mentioned off-white solid in 20mL of 10%wt sodium hydroxide solution, filter the insoluble matter to obtain the filtrate, then adjust the pH value of the filtrate to 1 with 1mol / L HCl, stand at room temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com