Low-temperature proton exchange membrane and preparation method thereof

A technology of proton exchange membrane and low temperature, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, fuel cells, etc. It can solve the problems of unguaranteed mechanical properties, hindering the application of proton exchange membranes, weak water absorption and water retention, etc., to achieve Good mechanical properties, simple preparation method, easy absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

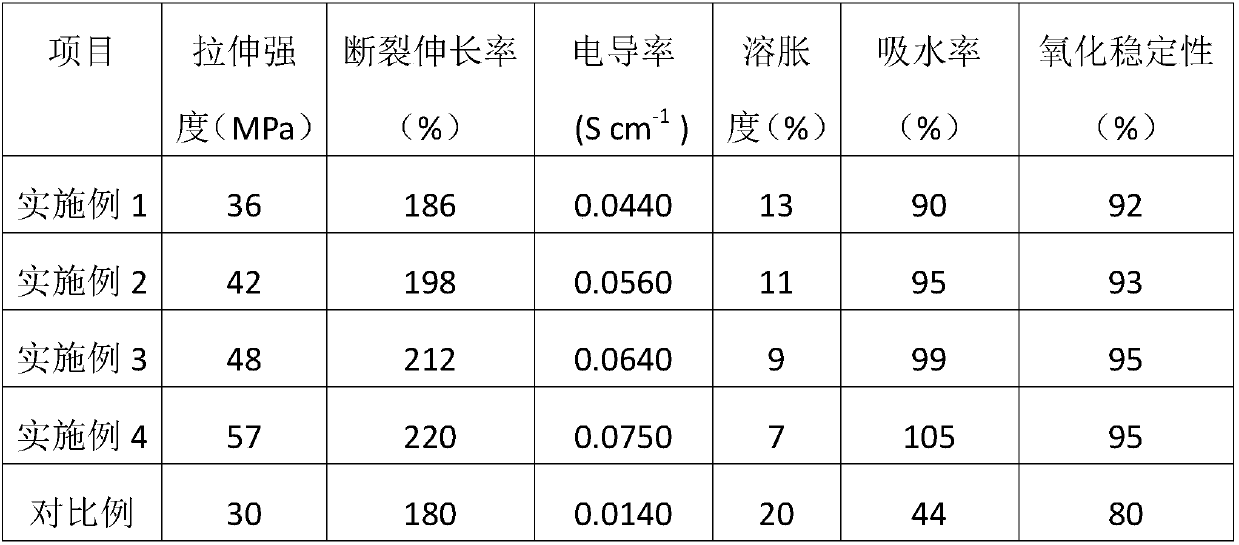

Embodiment 1

[0021] A preparation method for a low-temperature proton exchange membrane, comprising the steps of: tetrakis[4-(4'-carboxyphenyl)phenyl]ethylene 3g, diallyl disulfide 1g, carboxylated fullerene 0.3g, dodeca Mix 0.03g of sodium alkylbenzenesulfonate and 0.03g of benzoin, drop it on a glass plate, put it under a 220nm ultraviolet lamp under a nitrogen atmosphere, and illuminate it for 40 minutes to undergo a polymerization reaction to obtain a low-temperature proton exchange membrane;

[0022] A low-temperature proton exchange membrane prepared by the method for preparing a low-temperature proton exchange membrane;

[0023] A proton exchange membrane fuel cell adopts the low-temperature proton exchange membrane as a polymer electrolyte membrane.

Embodiment 2

[0025] A preparation method for a low-temperature proton exchange membrane, comprising the steps of: tetrakis[4-(4'-carboxyphenyl)phenyl]ethylene 3g, diallyl disulfide 1.2g, carboxylated fullerene 0.4g, poly Mix 0.04g of oxypropylene polyvinyl glyceryl ether with 0.04g of benzoin dimethyl ether, drop it on a glass plate, put it under a 250nm ultraviolet lamp under an argon atmosphere and illuminate it for 45 minutes, and a polymerization reaction occurs to obtain a low-temperature proton exchange membrane;

[0026] A low-temperature proton exchange membrane prepared by the method for preparing a low-temperature proton exchange membrane;

[0027] A proton exchange membrane fuel cell adopts the low-temperature proton exchange membrane as a polymer electrolyte membrane.

Embodiment 3

[0029] A preparation method for a low-temperature proton exchange membrane, comprising the steps of: tetrakis[4-(4'-carboxyphenyl)phenyl]ethylene 3g, diallyl disulfide 1.6g, carboxylated fullerene 0.45g, nonyl 0.05 g of phenol polyoxyethylene ether and 0.04 g of benzoin ethyl ether were mixed, dropped on a glass plate, placed under a 280 nm ultraviolet lamp under a neon gas atmosphere, and illuminated for 48 minutes to undergo a polymerization reaction to obtain a low-temperature proton exchange membrane;

[0030] A low-temperature proton exchange membrane prepared by the method for preparing a low-temperature proton exchange membrane;

[0031] A proton exchange membrane fuel cell adopts the low-temperature proton exchange membrane as a polymer electrolyte membrane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com