Furyl diacid monomer, soluble aromatic polyamide, repeatedly processable crosslinked polyamide as well as preparation method and application thereof

A technology of furanyl diacid monomer and aromatic polyamide, which is applied in the field of polyamide, can solve the problems of exacerbated energy crisis, high glass transition temperature and melting temperature, environmental pollution, etc., and achieve the reduction of environmental impact and waste of resources, The effect of enhancing mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

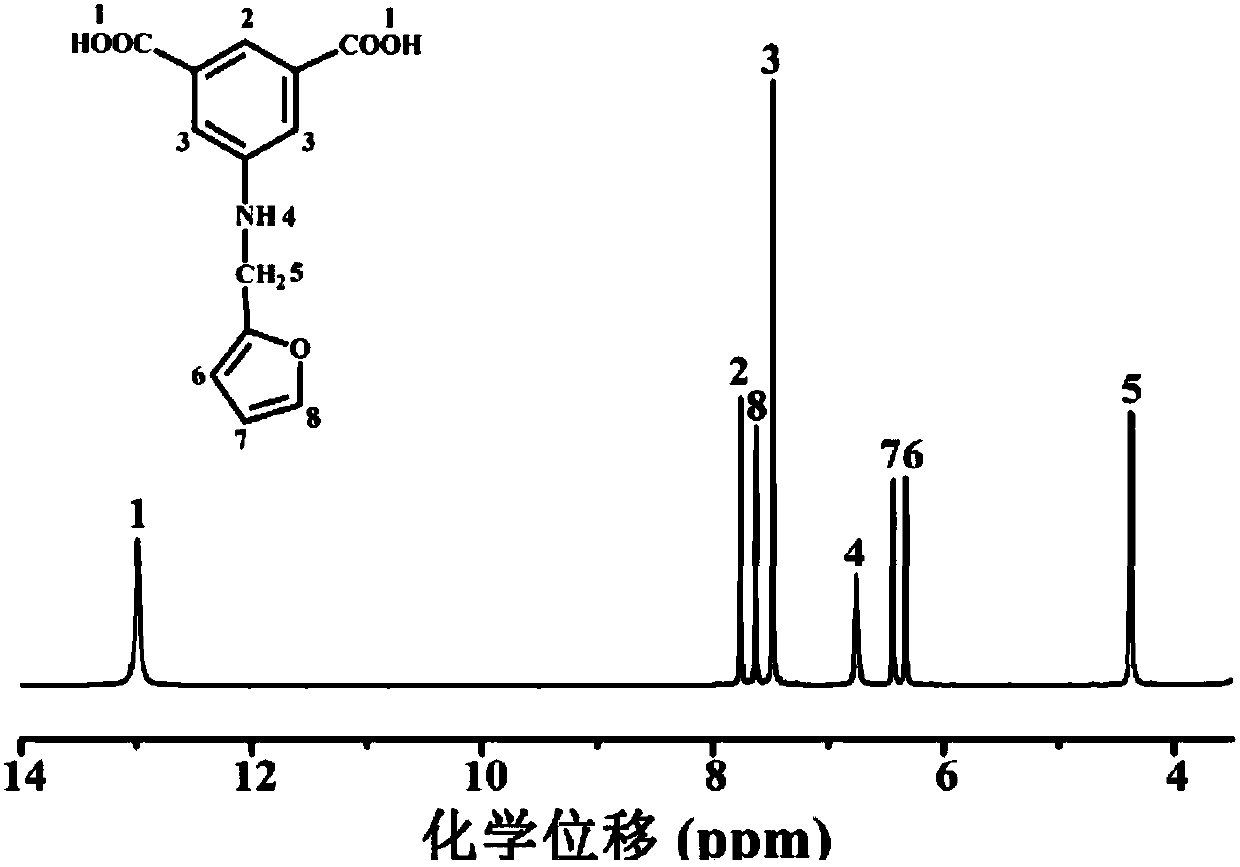

[0061] In an ice-water bath, add 30 mmol of 5-aminoisophthalic acid to an alcohol solvent (methanol, 300 ml), then add anhydrous sodium acetate with a mass fraction of 37% (2 g), and 5 to 10 drops of glacial acetic acid, and stir evenly ; Equimolar furfural (2.5ml) was added twice, and reacted for 4h; 4 times the equivalent of sodium borohydride was added four times, and the reaction was continued for 4h. Remove the solvent under reduced pressure to obtain a white solid, adjust the pH, precipitate the product, wash with deionized water for 3-5 times, and dry at 80°C to obtain the furanyl diacid monomer. The NMR spectrum is as follows: figure 1 Shown (68% yield).

Embodiment 2

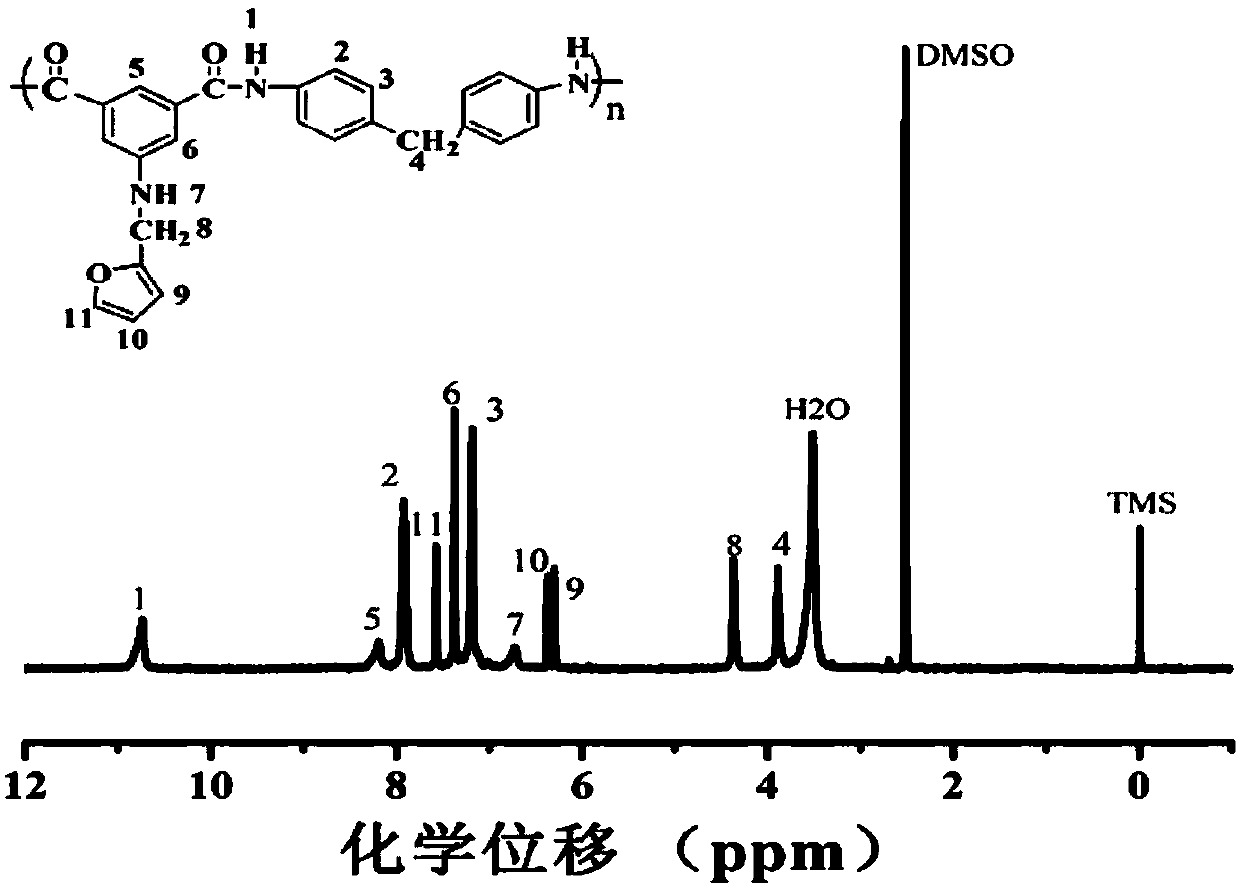

[0063] Inert gas (N at 90°C 2 ) under protection, metal salt diacid (1.4g) was added into polar solvent (NMP, 30ml), then furanyl diacid monomer (2.6123g) was added to obtain diacid solution; equimolar diamine mono The solid (p-phenylenediamine, 1.0814g) was added to the diacid solution and mixed evenly; the catalyst (pyridine 6ml; triphenyl phosphite 5.6ml) was added, the temperature was raised to 110°C for half an hour, and then the temperature was raised to 130°C for 4 hours. A light yellow viscous polymer solution was obtained. The polymer solution was poured into acetone for separation, exchanged in water for 24 hours, then soaked in ethanol for 24 hours, and then dried in an oven at 80°C to obtain furanyl soluble aromatic polyamide, nuclear magnetic spectrum Such as figure 2 Shown (89% yield).

Embodiment 3

[0065] The furan polyamide and cross-linked composite membrane were placed in the polar solvent NMP to test its solvent resistance. It can be seen that the pure polymer is soluble at room temperature, and the cross-linked polyamide film has shown strong solvent resistance; when the temperature is raised to 130 °, the cross-linked polymer also has good solubility ( image 3 A-1), the polyamide solution of dissolving can form gel again through 12h at 60 ° ( image 3 A-2); This gel-sol transformation process can be cycled at least three times. This kind of crosslinking at low temperature endows the material with excellent properties (such as solvent resistance, high strength, etc.), and the decrosslinking at high temperature makes the material have good processing performance and recyclable reuse performance, which saves resources and reduces It reduces environmental pollution and provides the possibility to recycle high-performance polymers. Its repetitive processing such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com