Graphene/boron nitride fiber composite and preparation method thereof

A boron nitride fiber and composite material technology, which is applied in fiber processing, textiles and papermaking, etc., can solve the problems of poor moisture resistance of boron nitride fibers, and achieve the effects of large application value, uniform distribution and high interface adhesion strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

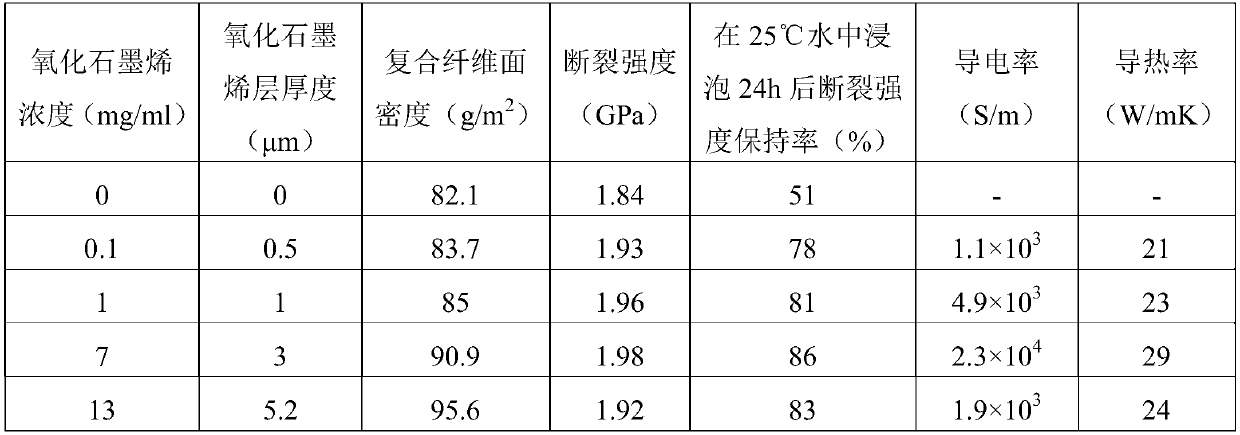

[0027] (1) The surface of the boron nitride fiber is repeatedly coated and dried with an aqueous dispersion of graphene oxide, and the number of cycles is 15 times to obtain a boron nitride fiber coated with graphene oxide on the surface. The thickness of the graphene oxide layer is 3 μm;

[0028] (2) The boron nitride fiber coated with graphene oxide obtained in step (3) is placed in water for surface swelling, and then the fibers are overlapped and dried to form a non-woven fabric, and the drying temperature is lower than 100°C.

[0029] (3) The graphene oxide crosslinked boron nitride fiber obtained in step (2) was placed in a closed kettle containing hydrazine hydrate, and reduced at 80° C. for 12 hours.

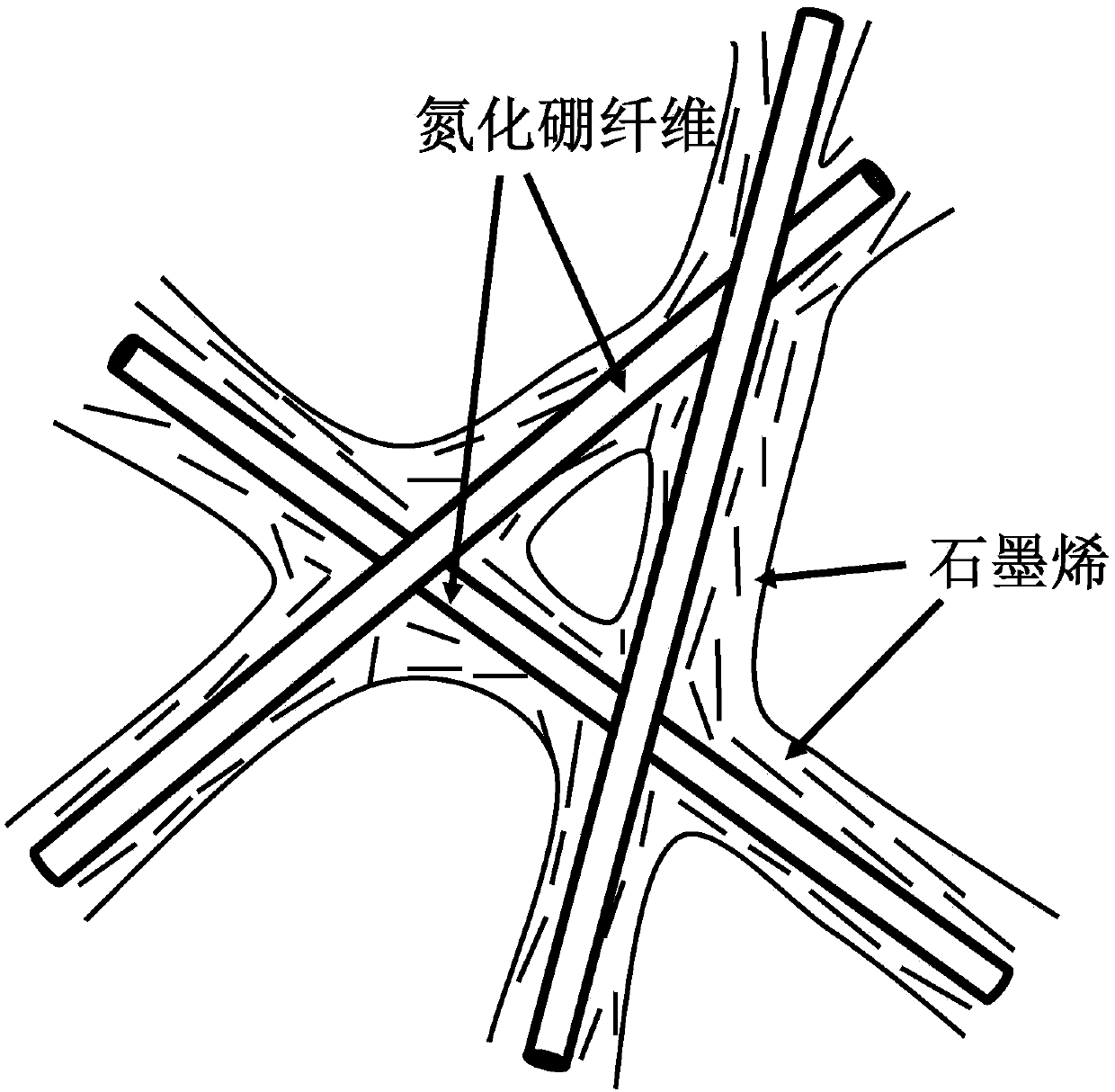

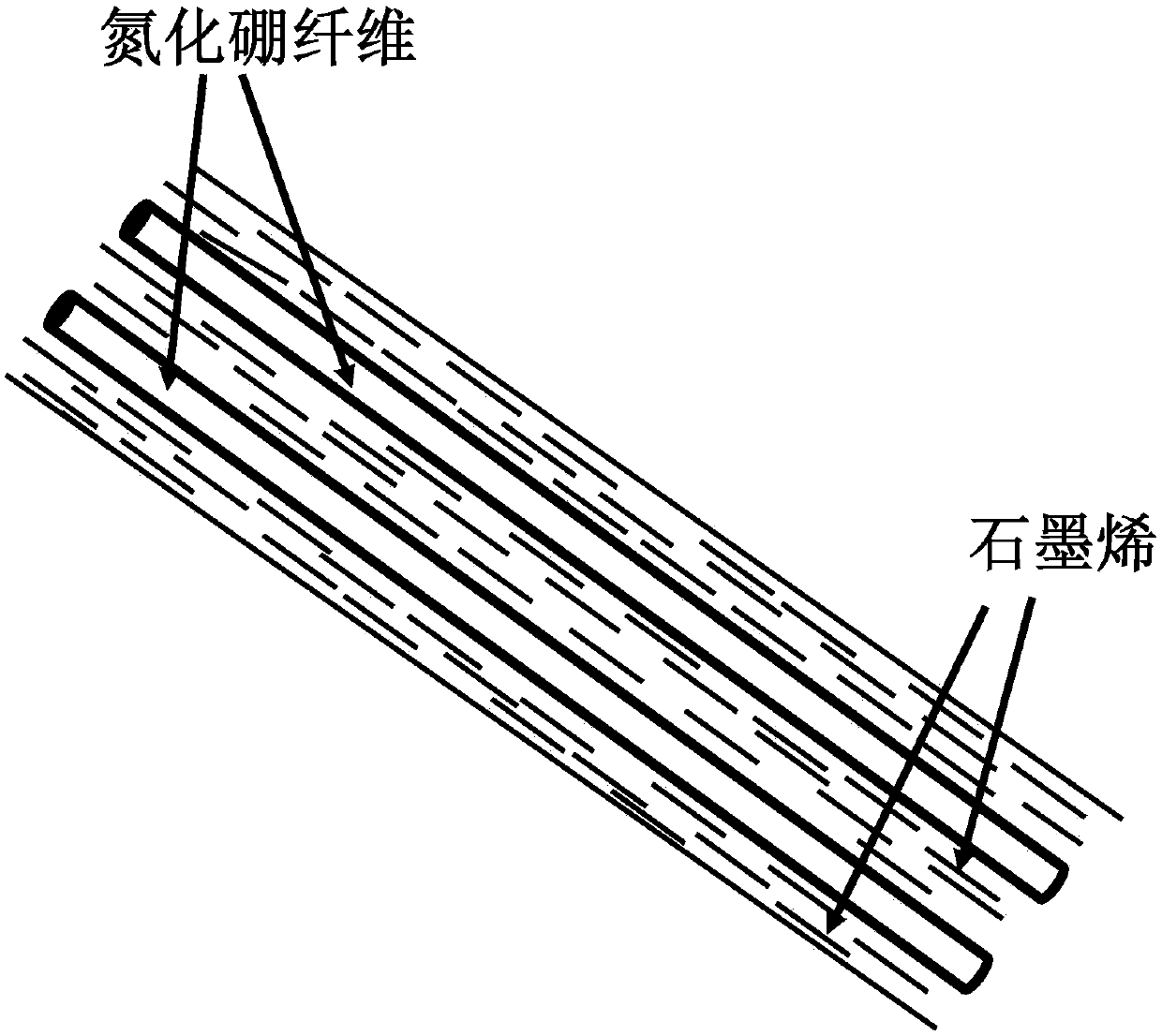

[0030] Through the above steps, the graphene is coated on the surface of the boron nitride fiber, and the surface of the boron nitride fiber and the graphene sheet are connected by van der Waals force and hydrogen bond. The boron nitride fibers are cross-linked through ...

Embodiment 2

[0034] (1) Use the N,N-dimethylformamide dispersion of graphene oxide to repeatedly coat and dry the surface of the boron nitride fiber, the number of cycles is 13 times, and obtain the boron nitride fiber coated with graphene oxide on the surface . The thickness of the graphene oxide layer is 3 μm;

[0035] (2) placing the graphene oxide-coated boron nitride fiber obtained in step (1) in water for surface swelling, and then overlapping the fibers with each other and drying to form a non-woven fabric at a drying temperature lower than 100°C.

[0036] (3) The graphene oxide crosslinked boron nitride fiber obtained in step (2) was placed in a closed kettle containing hydrazine hydrate, and reduced at 80° C. for 12 hours.

[0037] Through the above steps, the graphene is coated on the surface of the boron nitride fiber, and the surface of the boron nitride fiber and the graphene sheet are connected by van der Waals force and hydrogen bond. The boron nitride fibers are cross-lin...

Embodiment 3

[0039] (1) The surface of the boron nitride fiber was repeatedly coated and dried by using the ethanol dispersion of graphene oxide, and the number of cycles was 16 times to obtain a boron nitride fiber coated with graphene oxide on the surface. The thickness of the graphene oxide layer is 3 μm;

[0040] (2) The boron nitride fiber coated with graphene oxide obtained in step (3) is placed in water for surface swelling, and then the fibers are overlapped and dried to form a non-woven fabric, and the drying temperature is lower than 100°C.

[0041] (3) Place the graphene oxide crosslinked boron nitride fiber obtained in step (2) in a closed kettle containing hydroiodic acid, and reduce it at 90° C. for 18 hours.

[0042] Through the above steps, the graphene is coated on the surface of the boron nitride fiber, and the surface of the boron nitride fiber and the graphene sheet are connected by van der Waals force and hydrogen bond. The boron nitride fibers are cross-linked throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com