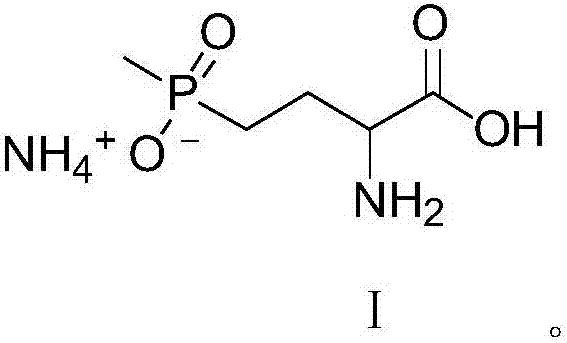

Preparation method of glufosinate-ammonium acid

A technology of glufosinate ammonium and phosphonic acid, applied in the field of pesticide chemistry, can solve the problems of cumbersome process, low separation yield, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

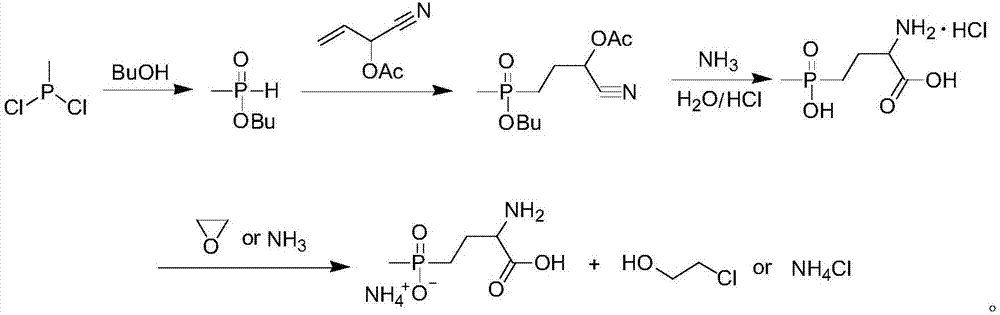

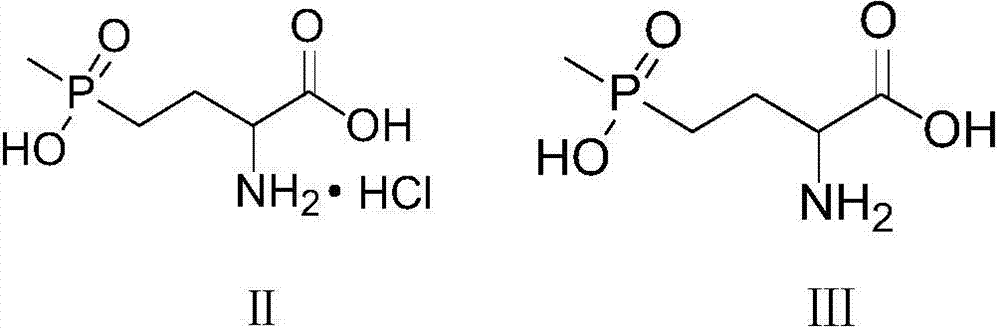

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 glufosinate-ammonium intermediate aminonitrile

[0030] At room temperature, add 5.61g of freshly distilled acrolein to 10.21g of acetic anhydride, and at 25-30°C, add the mixture of the two above to 13.61g of diethyl methylphosphonite and 4.6 g in a mixture of absolute ethanol. After stirring at 30°C for 2h, add dropwise at 25-28°C 4.9g of sodium cyanide and 10.7g of ammonium chloride in 50mL of ammonia solution (the mass fraction of ammonia water is 25%), react at 30°C for 2h, and react At the end, use a rotary evaporator to remove excess ammonia water, add 30g of dichloromethane to fully extract three times, after combining the extracts, concentrate and completely remove the dichloromethane to obtain the formula The shown glufosinate-ammonium aminonitrile is 20.2g, the purity is 92%, and the yield is 97.9%.

Embodiment 2

[0032] Get glufosinate-ammonium aminonitrile intermediate 103.5g (purity is 92%, 0.5mol) and place in four-necked flask, add sodium hydroxide solution (mass fraction is 10%) 440.2g, heat up to 80 ℃ for hydrolysis, and draw Slight negative pressure deamination, absorb the released ammonia with water, and the hydrolysis ends after 1 hour; add 69.5g of oxalic acid dihydrate to the hydrolyzate, raise the temperature to 80°C for salt-forming reaction, react for 20min, and concentrate 50% of the volume of the reaction solution % water, then cooled to 0°C, filtered to obtain the filtrate and sodium oxalate solid, rinsed the sodium oxalate solid with an appropriate amount of water, combined the washing liquid with the filtrate, concentrated the combined liquid to 40% of the original volume to obtain a concentrated liquid, and then added concentrated 2 times the volume of methanol, cooled to -5 ° C, fully stirred to precipitate glufosinate-ammonium solid, filtered, dried to obtain 75.5g...

Embodiment 3

[0034] Get glufosinate-ammonium aminonitrile intermediate 207.1g (purity is 92%, 1.0mol) and place in four-necked flask, add sodium hydroxide solution (mass fraction is 10%) 880.5g, heat up to 70 ℃ for hydrolysis, and draw Deamination under slight negative pressure, absorb the released ammonia gas with water, and the hydrolysis ends after 1 hour; add 139.8 g of oxalic acid dihydrate to the hydrolyzate, raise the temperature to 60°C to carry out the salt-forming reaction, and concentrate to account for 60% of the volume of the reaction solution after 20 minutes of reaction water, then cooled to 0°C, filtered to obtain the filtrate and sodium oxalate solid, rinsed the sodium oxalate solid with an appropriate amount of water, combined the washing liquid with the filtrate, concentrated the combined liquid to 45% of the original volume to obtain a concentrated liquid, and then added concentrated 1.8 times the volume of methanol, cooled to -5°C, fully stirred to precipitate glufosina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com