Method for preparing metal-tungsten-surface nano porous active layer

A nano-porous, active layer technology, applied in the direction of surface reaction electrolytic coating, nanotechnology, coating, etc., can solve the problems of inability to be popularized and applied in a large range, long preparation cycle, cumbersome process, etc., to shorten the preparation cycle and operate Simple, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

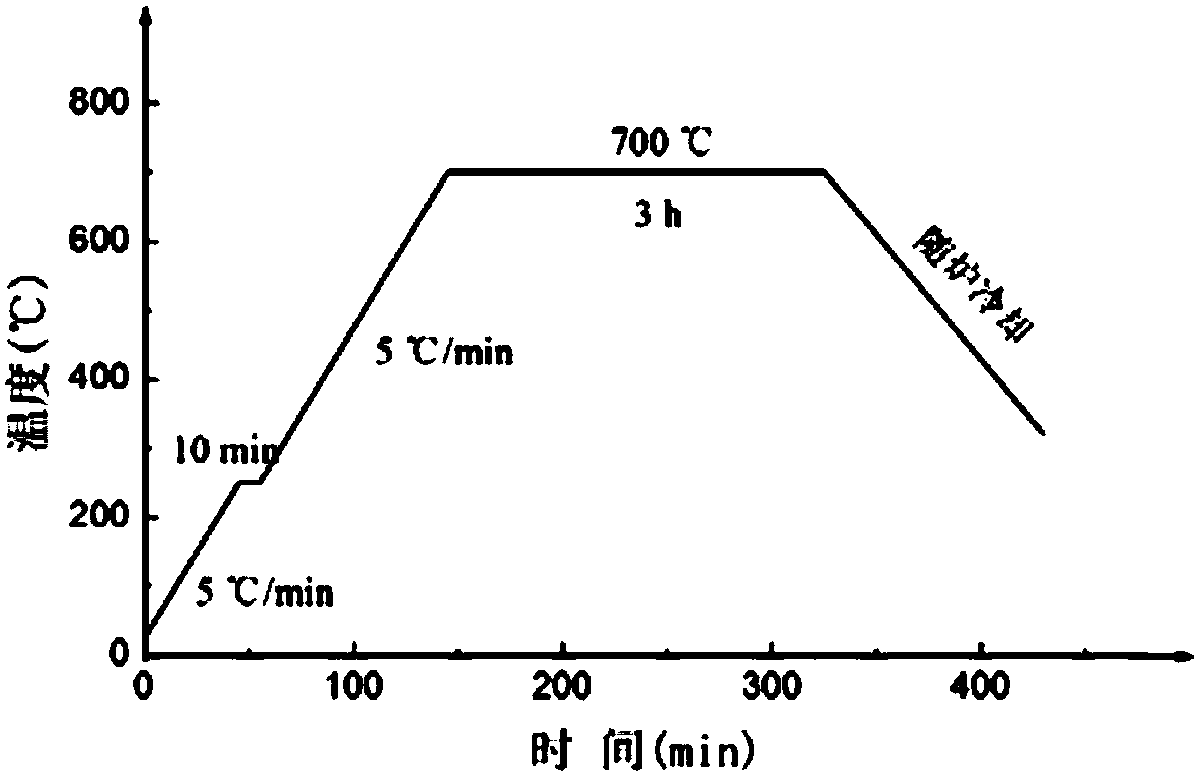

[0028] Embodiment 1: a kind of method for preparing nanoporous active layer on metal tungsten surface, the steps are as follows:

[0029] Step 1. Pretreatment of tungsten sheet, including surface grinding, degreasing, ultrasonic cleaning and drying.

[0030] Surface grinding: The surface of the tungsten sheet (purity ≥ 99.95%) with a size of 20×20×0.1mm is polished smooth with 800#, 1000#, 1500# metallographic sandpaper in sequence, and the grinding direction is rotated 90° every time the sandpaper is changed , until the previous grinding trace completely disappears, and finally only the grinding trace of 1500# sandpaper remains on the surface of the tungsten sheet;

[0031] Degreasing: ultrasonically clean the tungsten sheet polished with sandpaper in acetone, isopropanol, and methanol for 10 minutes;

[0032] Ultrasonic cleaning: Ultrasonic cleaning the degreased tungsten sheet in absolute ethanol and ultrapure water for 10 minutes respectively, after cleaning, put it in a ...

Embodiment 2

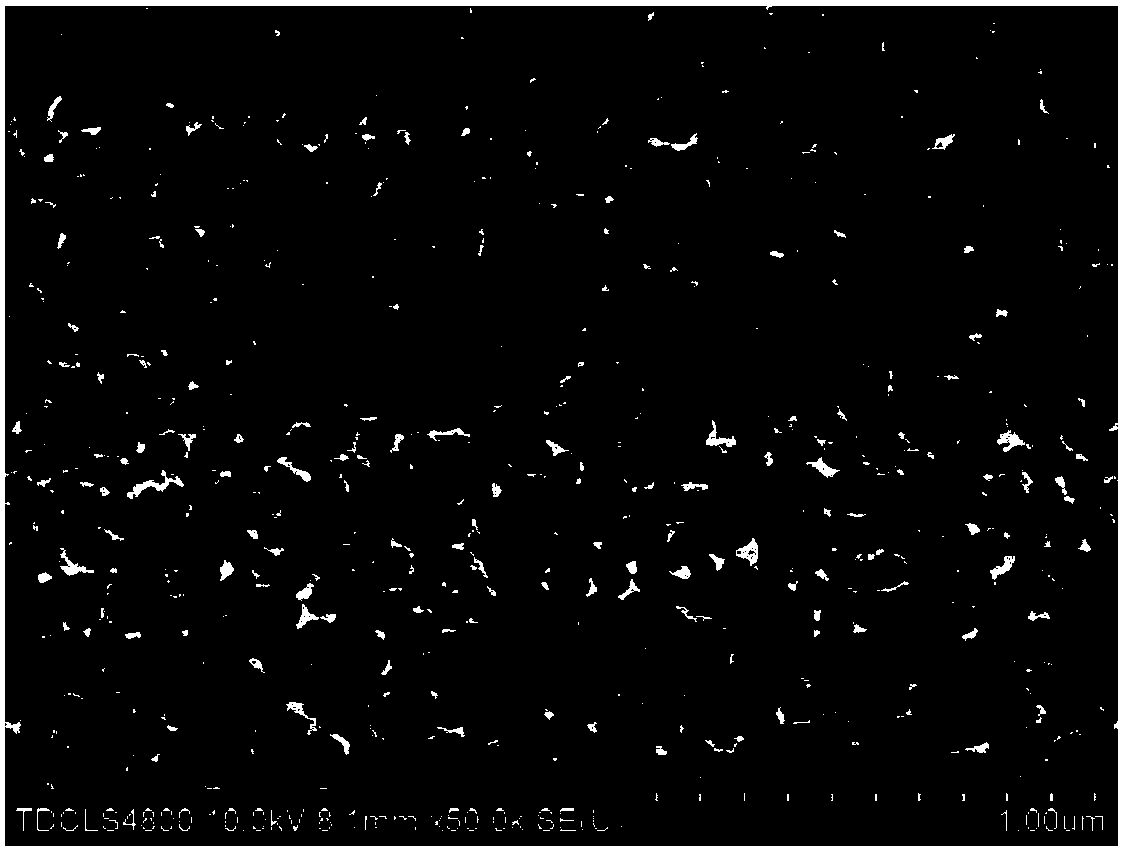

[0046] Embodiment 2. A method for preparing a nanoporous active layer on the surface of metal tungsten. The steps are basically the same as in Embodiment 1, except that in step 4, the annealing holding time at 700° C. is changed from 3 hours to 2 hours. The average pore size of the nanoporous metal layer on the surface of the finally obtained tungsten sheet is about 77nm, such as Figure 9 shown.

Embodiment 3

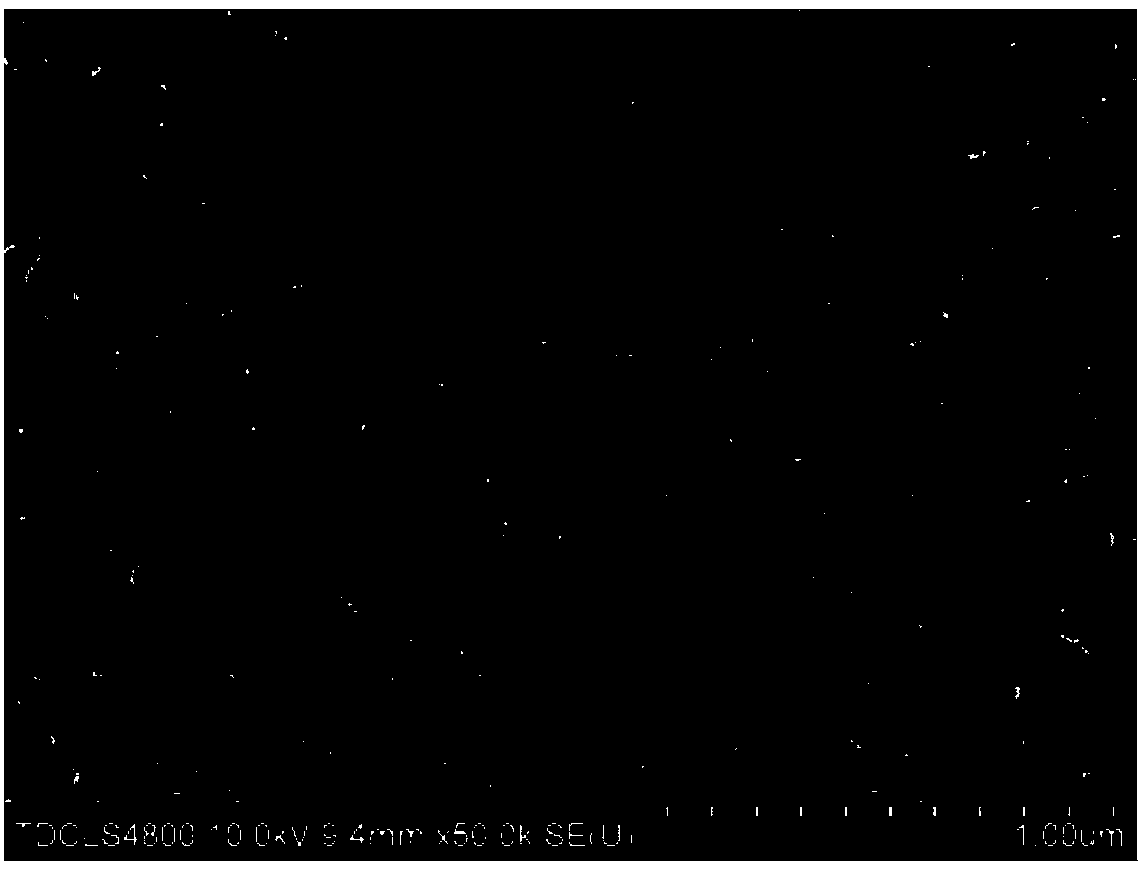

[0047] Example 3, a method for preparing a nanoporous active layer on the surface of metal tungsten, the steps are basically the same as in Example 1, the only difference is that in step 4, the annealing temperature is changed from 700°C to 600°C, and the holding time is changed from 3h to 4h . The average pore size of the nanoporous metal layer on the surface of the final tungsten sheet is about 77nm, such as Figure 10 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com